Sharp R-657SL (serv.man10) Service Manual ▷ View online

R657(W)

11 – 1

R657(W)

Service Manual

CHAPTER 11.

COMPONENT REPLACEMENT AND ADJUSTMENT PROCE-

DURE

[1] BEFORE OPERATING

Microwave ovens contain circuitry capable of producing very high voltage and current, contact with following parts may result in severe, possibly fatal,

electric shock.

electric shock.

(Example)

High Voltage Capacitor, High Voltage Transformer, Magnetron, High Voltage Rectifier Assembly, High Voltage fuse, High Voltage Harness etc..

WARNING:

Avoid possible exposure to microwave energy. Please follow the instructions below before operating

the oven.

the oven.

1) Disconnect the power supply cord.

2) Visually check the door and cavity face plate for damage (dents,

cracks, signs of arcing etc.).

Carry out any remedial work that is necessary before operating the

oven.

oven.

Do not operate the oven if any of the following conditions exist;

1) Door does not close firmly.

2) Door hinge, support or latch hook is damaged.

3) The door gasket or seal is damaged.

4) The door is bent or warped.

5) There are defective parts in the door interlock system.

6) There are defective parts in the microwave generating and trans-

mission assembly.

7) There is visible damage to the oven.

Do not operate the oven:

1) Without the RF gasket (Magnetron).

2) If the wave guide or oven cavity are not intact.

3) If the door is not closed.

4) If the outer case cabinet is not fitted.

To prevent an electric shock, take the following manners.

1. Before wiring,

1) Disconnect the power supply cord.

2) Open the door and block it open.

3) Discharge the high voltage capacitor and wait for 60 seconds.

2. Don't let the wire leads touch to the following parts;

1) High voltage parts:

Magnetron, High voltage transformer, High voltage capacitor

and High voltage rectifier assembly.

and High voltage rectifier assembly.

2) Hot parts:

Grill heating element, Oven lamp, Magnetron, High voltage

transformer and Oven cavity.

transformer and Oven cavity.

3) Sharp edge:

Bottom plate, Oven cavity, Waveguide flange, Chassis support

and other metallic plate.

and other metallic plate.

4) Movable parts (to prevent a fault)

Fan blade, Fan motor, Switch, Turntable motor and cooling fan.

3. Do not catch the wire leads in the outer case cabinet.

4. Insert the positive lock connector certainly until its pin is locked.

And make sure that the wire leads should not come off even if the

wire leads is pulled.

wire leads is pulled.

5. To prevent an error function, connect the wire leads correctly, refer-

ring to the Pictorial Diagram.

Please refer to ‘OVEN PARTS, CABINET PARTS, CONTROL PANEL PARTS, DOOR PARTS’, when carrying out any of the following removal proce-

dures:

dures:

[2] OUTER CASE CABINET REMOVAL

To remove the outer case cabinet, procedure as follows.

1. Disconnect the oven from power supply.

2. Open the oven door and wedge it open.

3. Remove the two screws from the exhaust duct (rear).

4. Slide the exhaust duct (rear) up and pull it away from the oven cav-

ity.

5. Remove the screws from the rear(4).

6. Slide the entire case back about 3 cm to free it from retaining clips

on the cavity face plate.

7. Lift the entire case from the oven.

8. Discharge the H.V. capacitor before carrying out any further work.

9. Do not operate the oven with the outer case cabinet removed.

CAUTION: DISCHARGE HIGH VOLTAGE CAPACITOR BEFORE

TOUCHING ANY OVEN COMPONENT OR WIRING.

[3] HIGH VOLTAGE COMPONENTS REMOVAL

(HIGH VOLTAGE CAPACITOR AND HIGH VOLTAGE RECTIFIER ASSEMBLY)

To remove the components, proceed as follows.

1. CARRY OUT 3D CHECKS.

2. Disconnect all the leads and terminals of high voltage rectifier from

high voltage capacitor.

3. Remove one (1) screw holding capacitor holder from the base

plate.

4. Remove one (1) screw holding earth side terminal of the high volt-

age rectifier assembly

WARNING AGAINST HIGH VOLTAGE:

WARNING FOR WIRING

R657(W)

11 – 2

5. Remove the capacitor from the capacitor holder.

6. Now the high voltage rectifier and capacitor should be free.

CAUTION: WHEN REPLACING HIGH VOLTAGE RECTIFIER

ASSEMBLY, ENSURE THAT THE CATHODE (EARTH)

CONNECTION IS SECURELY FIXED TO THE BASE

PLATE THROUGH THE CAPACITOR HOLDER WITH AN

EARTHING SCREW.

CONNECTION IS SECURELY FIXED TO THE BASE

PLATE THROUGH THE CAPACITOR HOLDER WITH AN

EARTHING SCREW.

[4] HIGH VOLTAGE TRANSFORMER REMOVAL

To remove the components, proceed as follows.

1. CARRY OUT 3D CHECKS.

2. Disconnect the primary connections from high voltage transformer.

3. Disconnect the filament leads of the high voltage transformer from

high voltage capacitor and the magnetron.

4. Disconnect the H.V. secondary wire (white) from the high voltage

capacitor.

5. Remove the two (2) screws holding the transformer to base plate.

6. Remove the transformer from the base plate by sliding it away from

the oven cavity and lifting it.

7. Disconnect the high voltage wire from the filament lead of the high

voltage transformer.

8. Now, the high voltage transformer is free.

[5] MAGNETRON REMOVAL

1. CARRY OUT 3D CHECKS.

2. Disconnect the H.V. wire and filament lead of the transformer from

the magnetron.

3. Remove the one (1) screw holding the air intake duct to the latch

hook.

4. Remove the one (1) screw holding the chassis support to the mag-

netron.

5. Move the air intake duct to left.

6. Carefully remove four (4) screws holding magnetron to the

waveguide.

7. Remove the magnetron from the waveguide with care so the mag-

netron antenna is not hit by any metal object around the antenna.

CAUTION: WHEN REPLACING THE MAGNETRON, BE SURE THE

R.F. GASKET IS IN PLACE AND THE MAGNETRON

MOUNTING SCREWS ARE TIGHTENED SECURELY.

MOUNTING SCREWS ARE TIGHTENED SECURELY.

[6] FAN MOTOR REREPLACEMENT

1. REMOVAL

1. CARRY OUT 3D CHECKS.

2. Disconnect the wire leads from the fan motor.

3. Remove the two (2) screws holding the fan motor to the oven cavity

back plate. The fan motor is now free.

4. Remove the fan blade from the fan motor shaft according to the fol-

lowing procedure.

i)

Hold the edge of the rotor of the fan motor by using a pair of

groove joint pliers.

groove joint pliers.

CAUTION: • Make sure that any pieces do not enter the gap

between the rotor and the starter of the fan motor.

Because the rotor is easy to be shaven by pliers and

metal pieces may be produced.

Because the rotor is easy to be shaven by pliers and

metal pieces may be produced.

• Do not let the pliers touch the coil of the fan motor

because the coil may be cut or damaged.

• Do not distort the bracket by touching with the pliers.

ii) Remove the fan blade from the shaft of the fan motor by pulling

and rotating the fan blade with your hand.

CAUTION: • Do not use this removed fan blade again. Because the

hole (for shaft) of it may become bigger than a standard

one.

one.

iii) Now, the fan blade will be free.

2. INSTALLATION

1. Install the fan blade to the fan motor shaft according to the following

procedure.

i)

Hold the centre of the bracket which supports the shaft of the

fan motor on a flat table.

fan motor on a flat table.

ii) Install the fan blade to the shaft of fan motor by pushing the fan

blade with a small, light weight, ball peen hammer or rubber

mallet.

mallet.

CAUTION: • Do not hit the fan blade when installing because the

bracket may be deformed.

• Make sure that the fan blade rotates smoothly after

installation.

• Make sure that the axis of the shaft is not slanted.

2. Install the fan motor to the oven cavity back plate with the two (2)

screws.

3. Re-connect the wire leads to the fan motor, referring to the pictorial

diagram.

Gap

Rotor

Bracket

Stator

Groove joint pliers

Coil

Shaft

Axis

Stator

Rotor

These are the positions

that should be pinched

with pliers.

that should be pinched

with pliers.

Shaft

Table

Center of

bracket

bracket

Rear View

Side View

R657(W)

11 – 3

[7] TURNTABLE MOTOR REPLACEMENT

1. Disconnect the oven from the power supply.

2. Remove the turntable motor cover by snipping off the material in

four corners.

3. Where the corners have been snipped off bent corner areas flat. No

sharp edge must be evident after removal of turntable motor cover.

4. Disconnect the wire leads from the turntable motor and remove the

one (1) screw holding the turntable motor.

5. Turntable motor is now free.

6. After replacement use one (1) screw to fit the turntable motor

cover.(XOTS740P08000)

[8] CONTROL PANEL ASSEMBLY REMOVAL

1. CARRY OUT 3D CHECKS.

2. Disconnect all the wire leads and the connectors from the control

panel.

3. Straighten the tab holding the control panel to the oven cavity face.

4. Lift up the control panel assembly and pull it forward.

Now the control panel assembly is free.

[9] GRAPHIC SHEET AND MEMBRANE SWITCH REPLACEMENT

1. REMOVAL

1. CARRY OUT 3D CHECKS.

2. Remove the control panel assembly, referring to chapter of CON-

TROL PANEL ASSEMBLY REMOVAL.

3. Disconnect the ribbon cable of the membrane switch from the con-

nector (CN-G) on the control unit.

4. Tear away the graphic sheet from the control panel frame.

5. Tear away the membrane switch from the control panel frame.

2. REINSTALL

1. Remove remaining adhesive on the control panel frame surfaces

with a soft cloth soaked in alcohol.

2. Tear the backing paper from the new membrane switch.

3. Insert the ribbon cable of the membrane switch into the slit of the

control panel frame.

4. Adjust the upper edge and right edge of the membrane switch to

the small depression on the surface of the control panel frame.

5. Attach the membrane switch to the control panel frame by rubbing

with a soft cloth not to scratch.

6. Tear the backing paper from the new graphic sheet.

7. Adjust the upper edge and right edge of the graphic sheet to the

large depression on the surface of the control panel frame.

8. Attach the graphic sheet to the control panel frame by rubbing with

a soft cloth not to scratch.

9. Connect the ribbon cable of the membrane switch to the connector

(CN-G) on the control unit.

NOTE: Do not contact the contact surface of the ribbon cable

(edge) and the rubber connector directly with your fin-

gers. This is to avoid oxidized. If display digits are miss-

ing or scrambled, remove control unit and clean contact

surface with alcohol. After cleaning, do not attach the rub-

ber connector until alcohol dries up. Do not use alcohol

or solution to clean the rubber connector. Make sure that

there is no trash or foreign substance on contact surface

of the rubber connector.

gers. This is to avoid oxidized. If display digits are miss-

ing or scrambled, remove control unit and clean contact

surface with alcohol. After cleaning, do not attach the rub-

ber connector until alcohol dries up. Do not use alcohol

or solution to clean the rubber connector. Make sure that

there is no trash or foreign substance on contact surface

of the rubber connector.

Figure C-1. Graphic Sheet and Membrane Switch Replace-

ment

[10] OVEN LAMP REMOVAL

1. CARRY OUT 3D CHECKS.

2. Disconnect the wire lead from the oven lamp.

3. Lift up the oven lamp from the clips of the air intake duct.

4. Now, the oven lamp is free.

Oven lamp

[11] GRILL HEATING ELEMENTS REMOVAL

1. CARRY OUT 3D CHECKS.

2. Remove the two (2) screws holding the two (2) terminals of the

main wire harness to the grill heating element.

Graphic sheet

Ribbon

cable

cable

Connector

(CN-G)

(CN-G)

Small depression

Control panel frame

Slit

Control unit

Membrane

switch

switch

Ribbon

cable

cable

Large

depression

depression

BULB

LOCK

R657(W)

11 – 4

3. Remove the one(1) screw holding the grill heater angle to the top of

the oven cavity.

4. Remove the grill heater angle from the oven cavity.

5. Remove the grill heating element from the top of the oven cavity.

6. Now the grill heating element is free.

[12] POWER SUPPLY CORD REPLACEMENT

1. REMOVAL

1. CARRY OUT 3D CHECKS.

2. Remove the one (1) screw holding the green/yellow wire to the

chassis support.

3. Disconnect the leads of the power supply cord from the noise filter,

referring to the Figure C-2(a).

4. Release the power supply cord from the oven cavity.

5. Now, the power supply cord is free.

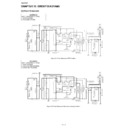

Figure C-2 (a) Replacement of Power Supply Cord

2. REINSTALL

1. Insert the moulding cord stopper of power supply cord into the

square hole of the power angle, referring to the Figure C-2(b).

2. Install the earth wire lead of power supply cord to the chassis sup-

port with one (1) screw and tight the screw.

3. Connect the brown and blue wire leads of power supply cord to the

noise filter correctly, referring to the Pictorial Diagram.

Figure C-2(b). Power Supply Cord Replacement

[13] MONITORED LATCH SWITCH, MONITOR SWITCH AND STOP SWITCH REMOVAL

1. REMOVAL

1. CARRY OUT 3D CHECKS.

2. Disconnect the wire leads from the switches and control panel.

3. Remove the control panel assembly from the oven cavity front

flange. Referring to chapter “CONTROL PANEL ASSEMBLY

REMOVAL”.

REMOVAL”.

4. Remove the one (1) screw holding the air intake duct to the latch

hook.

5. Remove the two (2) screws holding the latch hook to the oven

flange.

6. Remove the latch hook assembly from the oven flange.

7. To remove the switch.

1) With pushing outward on the tab that is holding the switch, turn

the switch so that the post is an axis.(Monitor Switch)

With pushing outward on the tab that is holding the switch, slide

the switch out of the latch hook. (Stop Switch and Monitored

Latch switch)

the switch out of the latch hook. (Stop Switch and Monitored

Latch switch)

2) Pull out the switch from the latch hook. Do not break the post or

tab of the latch hook.

3) Now the switch is free.

2. REINSTALL

1. Re-install each switch in its place. The monitored latch switch is in

the lower position and the monitor switch is in the middle position.

The stop switch is in the upper position.

The stop switch is in the upper position.

2. Re-connect wire leads to each switch. Refer to chapter “Pictorial

Diagram”.

3. Secure latch hook (with two (2) mounting screws) to oven flange.

4. Reinstall the air intake duct to the latch hook with the one (1) screw.

5. Re-install the control panel assembly to the oven cavity front

flange.

6. Re-connect wire leads to the control unit. Refer to chapter “Pictorial

Diagram”.

7. Make sure that monitor switch is operating properly and check con-

tinuity of the monitor circuit. Refer to chapter “Test Procedure”, and

Adjustment Procedure

Adjustment Procedure

Figure C-3. Switches

Power supply

cord

cord

Oven cavity

back plate

back plate

Chassis

support

support

BLU

G-Y

BRN

EARTH

Noise filter

RED

N

F2

F1

TP

TL

L

WHT

RED

RED

BLK

WHT

Power Supply

Cord

Cord

Oven Cavity

Rear Plate

Rear Plate

Moulding Cord

Stopper

Stopper

Square Hple

Latch hook

Tab

Stop switch

Monitor switch

Monitored latch switch

Tab

Tab

Display