Sharp R-464 (serv.man2) Service Manual ▷ View online

R-464(SL)

1

SERVICE MANUAL

MICROWAVE OVEN

R-464(SL)

GENERAL IMPORTANT INFORMATION

This Manual has been prepared to provide Sharp Corp. Service

engineers with Operation and Service Information.

engineers with Operation and Service Information.

It is recommended that service engineers carefully study the

entire text of this manual, so they will be qualified to render

satisfactory customer service.

entire text of this manual, so they will be qualified to render

satisfactory customer service.

CAUTION

MICROWAVE RADIATION

DO NOT BECOME EXPOSED TO RADIATION FROM

THE MICROWAVE GENERATOR OR OTHER PARTS

CONDUCTING MICROWAVE ENERGY.

THE MICROWAVE GENERATOR OR OTHER PARTS

CONDUCTING MICROWAVE ENERGY.

Service engineers should not be exposed to the microwave

energy which may radiate from the magnetron or other

microwave generating devices if it is improperly used or

connected. All input and output microwave connections,

waveguides, flanges and gaskets must be secured. Never

operate the device without a microwave energy absorbing

load attached. Never look into an open waveguide or

antenna while the device is energized.

energy which may radiate from the magnetron or other

microwave generating devices if it is improperly used or

connected. All input and output microwave connections,

waveguides, flanges and gaskets must be secured. Never

operate the device without a microwave energy absorbing

load attached. Never look into an open waveguide or

antenna while the device is energized.

WARNING

Never operate the oven until the following points are ensured.

(A) The door is tightly closed.

(B) The door brackets and hinges are not defective.

(C) The door packing is not damaged.

(D) The door is not deformed or warped.

(E) There is not any other visible damage with the oven.

(A) The door is tightly closed.

(B) The door brackets and hinges are not defective.

(C) The door packing is not damaged.

(D) The door is not deformed or warped.

(E) There is not any other visible damage with the oven.

Servicing and repair work must be carried out only by trained

service engineers.

service engineers.

All the parts marked "*" on parts list are used at voltages more

than 250V.

than 250V.

Removal of the outer wrap gives access to potentials above

250V.

250V.

All the parts marked "

∆

" on parts list may cause undue micro-

wave exposure, by themselves, or when they are damaged,

loosened or removed.

loosened or removed.

SHARP CORPORATION

OSAKA, JAPAN

PRODUCT SPECIFICATIONS

APPEARANCE VIEW

OPERATING SEQUENCE

FUNCTION OF IMPORTANT

COMPONENTS

COMPONENTS

SERVICING AND

TROUBLESHOOTING CHART

TROUBLESHOOTING CHART

TEST PROCEDURE

TOUCH CONTROL PANEL

ASSEMBLY

ASSEMBLY

COMPONENT REPLACEMENT

AND ADJUSTMENT PROCEDURE

AND ADJUSTMENT PROCEDURE

MICROWAVE MEASUREMENT

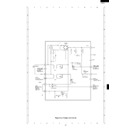

WIRING DIAGRAM

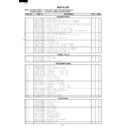

PARTS LIST

R-464(SL)

3

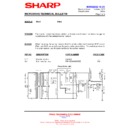

APPEARANCE VIEW

1 Door opening handle

2 Control panel

3 Digital display

4 See through door

7 Door latches

6 Door hinges

7 Door seals and sealing surfaces

8 Coupling

9 Oven cavity

10 Oven lamp

11 Waveguide cover

12 Ventilation openings

13 Outer case cabinet

14 Power cord

15 Turntable

16 Turntable support

2 Control panel

3 Digital display

4 See through door

7 Door latches

6 Door hinges

7 Door seals and sealing surfaces

8 Coupling

9 Oven cavity

10 Oven lamp

11 Waveguide cover

12 Ventilation openings

13 Outer case cabinet

14 Power cord

15 Turntable

16 Turntable support

1. EXPRESS COOK keys

Use to cook 7 popular foods.

2. EXPRESS DEFROST keys

Use to defrost 3 popular foods.

3. INSTANT COOK keys

Use to cook 3 popular foods. menus. (See NOTE.)

4. DIGITAL DISPLAY

5. WEIGHT CONVERSION key

5. WEIGHT CONVERSION key

Use to change weight, e.g. Kg/g to Lb/oz.

6. KITCHEN TIMER key

Press to use as a minute timer, or to programme

standing time.

standing time.

7. TIME key

Use to enter clocking time.

8. POWER LEVEL key

Press to select microwave power level.

2

5

4

11 5

7

10

9

1

6

3

8

12

14

13

15

16

Coupling

1

7

9

8

6

5

2

3

12

11

10

13

4

TOUCH CONTROL PANEL

9. START/ AUTO MINUTE key

Press to start a programme. Press to cook on 100P for

1 minute on or increase time during cooking in multiples

of 1 minute. (See NOTE.)

1 minute on or increase time during cooking in multiples

of 1 minute. (See NOTE.)

10.STOP/CLEAR key

Press once to stop a programme, twice to cancel a

programme.

programme.

11.LESS/ MORE keys

Press to shorten/ lengthen cooking time.

12.WEIGHT keys

Press up or down to select correct weight/ number of

pieces.

When the minimum (or maximum) weight/ number is

reached, the display will not change, even if you

continue to press the DOWN (or UP) key.

pieces.

When the minimum (or maximum) weight/ number is

reached, the display will not change, even if you

continue to press the DOWN (or UP) key.

13.CLOCK SET key

Use to set the clock or display the time.

NOTE:

The directed features are disabled after three minutes when the oven is not in use. These features are

automatically enabled when the door is opened and closed or the STOP/ CLEAR pad is pressed.

The directed features are disabled after three minutes when the oven is not in use. These features are

automatically enabled when the door is opened and closed or the STOP/ CLEAR pad is pressed.

R-464(SL)

4

OPERATION SEQUENCE

OFF CONDITION

Closing the door activates all door interlock switches

(1st. latch switch, 2nd. interlock relay control switch).

(1st. latch switch, 2nd. interlock relay control switch).

IMPORTANT

When the oven door is closed, the monitor switch contacts

(COM-NC) must be open.

When the microwave oven is plugged in a wall outlet, rated

voltage is supplied to the noise filter and the control unit.

When the oven door is closed, the monitor switch contacts

(COM-NC) must be open.

When the microwave oven is plugged in a wall outlet, rated

voltage is supplied to the noise filter and the control unit.

Figure O-1 on page 25

1. The display will show flashing "88:88".

2. To set any programmes or set the clock, you must

2. To set any programmes or set the clock, you must

first touch the STOP/CLEAR pad.

3. : appears in the display.

NOTE: When the oven door is opened, the oven lamp

comes on at this time.

MICROWAVE COOKING CONDITION

HIGH COOKING

Enter a desired cooking time with the touching TIME keys

and start the oven with touching STARTkey.

Enter a desired cooking time with the touching TIME keys

and start the oven with touching STARTkey.

Function sequence

Figure O-2 on page 25

CONNECTED COMPONENTS

RELAY

Oven lamp, Fan motors, Turntable motor

RY1

High voltage transformer

RY2

1. Rated voltage is supplied to the primary winding of the

high voltage transformer. The voltage is converted to

about 3.3 volts A.C. output on the filament winding and

high voltage of approximately 2000 volts A.C. on the

secondary winding.

about 3.3 volts A.C. output on the filament winding and

high voltage of approximately 2000 volts A.C. on the

secondary winding.

2. The filament winding voltage (3.3 volts) heats the

magnetron filament and the high voltage (2000 volts) is

sent to the voltage doubling circuit, where it is doubled

to negative voltage of approximately 4000 volts D.C..

sent to the voltage doubling circuit, where it is doubled

to negative voltage of approximately 4000 volts D.C..

3. The 2450 MHz microwave energy produced in the

magnetron generates a wave length of 12.24 cm. This

energy is channeled through the waveguide (transport

channel) into the oven cavity, where the food is placed

to be cooked.

energy is channeled through the waveguide (transport

channel) into the oven cavity, where the food is placed

to be cooked.

4. When the cooking time is up, a signal tone is heard and

the relays RY1+RY2 go back to their home position.

The circuits to the oven lamp, high voltage transformer,

fan motors and turntable motor are cut off.

The circuits to the oven lamp, high voltage transformer,

fan motors and turntable motor are cut off.

5. When the door is opened during a cook cycle, the

switches come to the following condition

CONDITION

DURING

DURING

DOOR OPEN

SWITCH

CONTACT

COOKING

(NO COOKING)

1st. interlock switch

COM-NO

Closed

Open

2nd. interlock relay

control switch

control switch

COM-NO

Closed

Open

Monitor switch

COM-NC

Open

Closed

The circuits to the high voltage transformer, fan motors

and turntable motor are cut off when the 1st. interlock

switch and 2nd. interlock relay control switch are made

open. The oven lamp remains on even if the oven door

and turntable motor are cut off when the 1st. interlock

switch and 2nd. interlock relay control switch are made

open. The oven lamp remains on even if the oven door

is opened after the cooking cycle has been interrupted,

because the relay RY1 stays closed. Shown in the

display is the remaining time.

because the relay RY1 stays closed. Shown in the

display is the remaining time.

6.

MONITOR SWITCH CIRCUIT

The monitor switch is mechanically controlled by

oven door, and monitors the operation of the 1st.

interlock switch and the relay RY1.

The monitor switch is mechanically controlled by

oven door, and monitors the operation of the 1st.

interlock switch and the relay RY1.

6-1 When the oven door is opened during or after the

cycle of a cooking program, the 1st. interlock switch

and 2nd. interlock relay control switch must open their

contacts first.

After that the contacts (COM-NC) of the monitor

switch can be closed.

and 2nd. interlock relay control switch must open their

contacts first.

After that the contacts (COM-NC) of the monitor

switch can be closed.

6-2. When the oven door is closed, the contacts (COM-

NC) of the monitor switch must be opened. After that

the contacts of the 1st. interlock switch and 2nd.

interlock relay control switch are closed.

the contacts of the 1st. interlock switch and 2nd.

interlock relay control switch are closed.

6-3. When the oven door is opened and the contacts of

the1st. interlock switch and the relay RY1 remain

closed, the fuse will blow, because the monitor switch

is closed and a short circuit is caused.

closed, the fuse will blow, because the monitor switch

is closed and a short circuit is caused.

NOTE FOR FUSE:

Fuse M10A is used util serial number 0109xxxxx.

Fuse F10A is used from serial number 0110xxxxx.

Fuse M10A is used util serial number 0109xxxxx.

Fuse F10A is used from serial number 0110xxxxx.

MEDIUM HIGH, MEDIUM, MEDIUM LOW, LOW

COOKING

COOKING

When the microwave oven is preset for variable cooking

power, rated voltage is supplied to the power transformer

intermittently within a 32-second time base through the

relay contact which is coupled with the current-limiting

relay RY2. The following levels of microwave power are

given.

power, rated voltage is supplied to the power transformer

intermittently within a 32-second time base through the

relay contact which is coupled with the current-limiting

relay RY2. The following levels of microwave power are

given.

SETTING;

NOTE: The ON/OFF time ratio does not exactly correspond

to the percentage of microwave power, because

approx. 3 seconds are needed for heating up the

magnetron filament.

approx. 3 seconds are needed for heating up the

magnetron filament.

POWER OUTPUT REDUCTION

After 100% power cooking mode is carried out for more

than 40 minutes, the power out-put is automatically re-

duced to 70%. Even if the cooking time is shorter than for

40 minutes, the power output is reduced to 70% after total

cooking time over 40 minutes when the oven is started in

100% power cooking mode again within 1 minute and 35

seconds.

than 40 minutes, the power out-put is automatically re-

duced to 70%. Even if the cooking time is shorter than for

40 minutes, the power output is reduced to 70% after total

cooking time over 40 minutes when the oven is started in

100% power cooking mode again within 1 minute and 35

seconds.

100P (HIGH)

32 sec. ON

70P (MEDIUM

HIGH)

Approx. 70%

100%

24 sec. ON

8 sec. OFF

14 sec. OFF

20 sec. OFF

26 sec. OFF

50P (MEDIUM)

Approx. 50%

18 sec. ON

30P (MEDIUM

LOW)

Approx. 30%

12 sec. ON

10P (LOW)

Approx. 10%

6 sec. ON

R-464(SL)

5

FUNCTION OF IMPORTANT COMPONENTS

THERMAL CUT-OUT (OVEN)

The thermal cut-out, located on the top of the oven cavity,

is designed to prevent damage to the oven by fire. If the

foods load is overcooked, by either error in cook time or

defect in the control unit, the thermal cut-out will open.

Under normal operation, the oven thermal cut-out remains

closed. However, when abnormally high temperatures are

reached within the oven cavity, the oven thermal cut-out

will open at 125˚C, causing the oven to shut down. The

defective thermal cut-out must be replaced with new one.

is designed to prevent damage to the oven by fire. If the

foods load is overcooked, by either error in cook time or

defect in the control unit, the thermal cut-out will open.

Under normal operation, the oven thermal cut-out remains

closed. However, when abnormally high temperatures are

reached within the oven cavity, the oven thermal cut-out

will open at 125˚C, causing the oven to shut down. The

defective thermal cut-out must be replaced with new one.

THERMAL CUT-OUT (MAGNETRON)

The thermal cut-out located near the magnetron is de-

signed to prevent damage to the magnetron if an over

heated condition develops in the tube due to cooling fan

failure, obstructed air guide, dirty or blocked air intake, etc.

Under normal operation, the thermal cut-out remains

closed. However, when abnormally high temperatures are

reached within the magnetron, the thermal cut-out will

open at 125˚C causing the oven to shut down. The

defective thermal cut-out must be replaced with new one.

signed to prevent damage to the magnetron if an over

heated condition develops in the tube due to cooling fan

failure, obstructed air guide, dirty or blocked air intake, etc.

Under normal operation, the thermal cut-out remains

closed. However, when abnormally high temperatures are

reached within the magnetron, the thermal cut-out will

open at 125˚C causing the oven to shut down. The

defective thermal cut-out must be replaced with new one.

THERMOSTAT 150˚C IN HIGH VOLTAGE TRANS-

FORMER

FORMER

The thermostat protects the high voltage transformer

against over heating. If the temperature goes up higher

than 150˚C because the fan motor is interrupted or the

ventilation openings are blocked, the thermostat will cycle,

line voltage to the high voltage transformer will also cycle.

(If operated, check the magnetron for damage.)

against over heating. If the temperature goes up higher

than 150˚C because the fan motor is interrupted or the

ventilation openings are blocked, the thermostat will cycle,

line voltage to the high voltage transformer will also cycle.

(If operated, check the magnetron for damage.)

TURNTABLE MOTOR

The turntable motor drives the turntable roller assembly to

rotate the turntable.

rotate the turntable.

FAN MOTOR

The fan motor drives a blade which draws external cool air.

This cool air is directed through the air vents surrounding

the magnetron and cools the magnetron. This air is

channeled through the oven cavity to remove steam and

vapors given off from the heating foods. It is then ex-

hausted through the exhausting air vents at the oven

cavity

This cool air is directed through the air vents surrounding

the magnetron and cools the magnetron. This air is

channeled through the oven cavity to remove steam and

vapors given off from the heating foods. It is then ex-

hausted through the exhausting air vents at the oven

cavity

NOISE FILTER

The noise filter prevents the radio frequency interference

that might flow back in the power circuit.

that might flow back in the power circuit.

DOOR OPEN MECHANISM

The door is opened by pulling the door, refer to the Figure

D-1.

D-1.

Figure D-1. Door Open Mechanism

1ST. INTERLOCK SWITCH AND 2ND. INTERLOCK

RELAY CONTROL SWITCH

RELAY CONTROL SWITCH

1. When the oven door is closed, the contacts (COM-NO)

must be closed.

2. When the oven door is opened, the contacts (COM-

NO) must be opened.

MONITOR SWITCH

1. When the oven door is closed, the contacts (COM-NC)

must be opened.

2. When the oven door is opened, the contacts (COM-

NC) must be closed.

3. If the oven door is opened and the contacts (COM-NO)

of the 1st. interlock switch and the relay RY1 fail to

open, the fuse blows simultaneously with closing the

contacts (COM-NC) of the monitor switch.

open, the fuse blows simultaneously with closing the

contacts (COM-NC) of the monitor switch.

CAUTION: BEFORE REPLACING A BLOWN FUSE

TEST THE 1ST. INTERLOCK SWITCH, RE-

LAY RY1, MONITOR SWITCH AND MONI-

TOR RESISTOR FOR PROPER OPERA-

TION.

LAY RY1, MONITOR SWITCH AND MONI-

TOR RESISTOR FOR PROPER OPERA-

TION.

MONITOR RESISTOR 0.8

Ω

20W

The monitor resistor prevents the fuse bursting when the

fuse blows due to the operation of the monitor switch.

fuse blows due to the operation of the monitor switch.

HIGH VOLTAGE FUSE

The high voltage fuse blows when the high voltage rectifier

or magnetron is shorted.

or magnetron is shorted.

FUSE

1. The fuse blows when the contacts (COM-NO) of the

1st. interlock switch and the relay RY1 remain closed

with the oven door open and when the monitor switch

closes.

with the oven door open and when the monitor switch

closes.

2. If the wire harness or electrical components are short-

circuited, this fuse blows to prevent an electric shock or

fire hazard.

fire hazard.

NOTE: Fuse M10A is used util serial number

0109xxxxx.

Fuse F10A is used from serial number

0110xxxxx.

Fuse F10A is used from serial number

0110xxxxx.

Latch

Heads

Heads

Door

Latch Hook

2nd. Interlock

Relay Control

Switch

Relay Control

Switch

1st. Interlock

Switch

Switch

Monitor Switch