Sharp DV-L70 (serv.man24) Service Manual ▷ View online

DV-L70S

DV-L70BL

DV-L70W

8

Parts Code

Price Code

Remarks

Parts Code

Price Code

Remarks

QCNW-8145GEZZ

AQ

P.U. extension, 30-pin

QCNW-8151GEZZ

AQ

Inverter extension, 6-pin

QCNW-8146GEZZ

AQ

Spindle extension, 13-pin

QCNW-8152GEZZ

AQ

LCD panel extension, 32-pin

QCNW-8147GEZZ

AN

Sled extension, 2-pin

QCNW-8154GEZZ

AQ

Operation PWB extension, 12-pin

QCNW-8148GEZZ

AM

Power supply extension, 14-pin QCNW-1766TAZZ

BF

Inverter junction PWB

QCNW-8149GEZZ

AQ

Main LCD extension, 14-pin

QPWBF5002GEZZ

BF

LCD junction PWB

QCNW-8150GEZZ

AQ

Main LCD extension, 14-pin

QPWBF5003GEZZ

BF

Pickup junction PWB

Adjustment VR

R1102

Adjustment Point

Put a voltmeter between 6PIN (+7.5V) and 4PIN (GND) of TP1191.

Input Signal/Setting

No input

Adjustment Method

Adjust it to 7.50

±

0.02V.

Adjustment VR

R1103

Adjustment Point

Visual observation of the panel

Input Signal/Setting

Monoscope full screen

Adjustment Method

Adjust the screen so that it is located in the center.

Adjustment VR

R1104

Adjustment Point

Observe the 3PIN of TP1191 with a frequency counter.

Input Signal/Setting

No input, external input mode

Adjustment Method

Adjust it so as to get the HSY frequency of 15.625

±

0.01KHz

(64.0

µ

S).

HSY

15.625KHz

(64.0

µ

S)

6-2. ADJUSTMENT PROCEDURE AND METHOD OF LCD PWB SIDE

1. 7.5V adjustment

2. Free run adjustment

3. Screen center adjustment

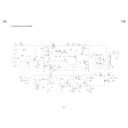

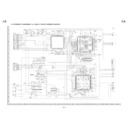

Drawing for service jigs

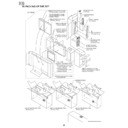

Operation cabinet

Mechanism

Power

supply PWB

supply PWB

PA

AE

AD

AC

AA

CN302

CN301

AB

MA

FFC

FFC spindle

Lead wire

FFC

Pickup junction PWB

QPWBF5003GEZZ

QPWBF5003GEZZ

Pickup

QCNW-8145GEZZ

QCNW-8145GEZZ

QCNW-8146GEZZ

QCNW-8147GEZZ

Sled

Sled

Power supply, 14-pole

QCNW-8148GEZZ

QCNW-8148GEZZ

QCNW-8154GEZZ

QCNW-8150GEZZ

LCD junction

QCNW-8152GEZZ

QCNW-8152GEZZ

LCD junction PWB

QPWBF5002GEZZ

QPWBF5002GEZZ

Inverter junction PWB

QCNW-1766TAZZ

QCNW-1766TAZZ

Inverter

QCNW-8151GEZZ

QCNW-8151GEZZ

Inverter PWB

QCNW-8149GEZZ

Lead wire

LC

LB

LA

LCD

LCD PWB

F

F

C

F

F

C

Panel

Main PWB

6. ADJUSTMENT METHOD

6-1. HARNESS LIST FOR SERVICE PARTS

9

DV-L70S

DV-L70BL

DV-L70W

Adjustment Point

Put voltmeters in 4PIN (GND), 5PIN (-16V) and 7PIN (13V) of TP1191.

Input Signal/Setting

Check in the DVD mode.

Adjustment Method

Check that each voltage indicates -16

±

1V and 13

±

0.5V respectively.

6-3. CHECK ITEMS OF LCD PWB SIDE

1. Power supply voltage check

Adjustment Point

Check the panel visually by connecting to the checker.

Input Signal/Setting

External input

Adjustment Method

Check that the horizontal movement of ODS is 1 mm or less when

inputting a signal in the external input mode with no signal input.

2. Free run check

Input

6-4. ADJUSTMENT PROCEDURE AND METHOD OF MAIN PWB SIDE

1. Press the UP+DOWN key is pushed at the same time, and made power source on.

2. It moves to the special mode(SP MODE), and a BACKLIGHT(HI/LOW/OFF) key is pushed and turned off.

3. After setting is completed, a power source is turned off.

4. Again, a UP+DOWN key is pushed at the same time, and a power source is turned on and made special mode.

5. An INPUT/ DVD key is pushed, and it becomes adjustment mode.

6. Each operation in the adjustment mode changes as follows:

2. It moves to the special mode(SP MODE), and a BACKLIGHT(HI/LOW/OFF) key is pushed and turned off.

3. After setting is completed, a power source is turned off.

4. Again, a UP+DOWN key is pushed at the same time, and a power source is turned on and made special mode.

5. An INPUT/ DVD key is pushed, and it becomes adjustment mode.

6. Each operation in the adjustment mode changes as follows:

(1) Switch the adjustment block with the TILT key input.

(2) Perform paging of each adjustment block with the RETARN key.

(3) Switch each adjustment item with the menu key input.

(4) Change each adjustment value with the left or right cursor key.

DAC adjustment

OPT adjustment

BAT adjustment

TV1

TV2

TV3

GAM0

TV1 adjustment

TV2 adjustment

TV3 adjustment

SBRI

GPOS

CONT

WB-R

WB-B

SCOL

STIN

COM

OSDH

BBRI

GAM2

DV-L70S

DV-L70BL

DV-L70W

10

1. DAC adjustment

(1) TV1 adjustment

(1) TV1 adjustment

Adjustment VR

GAM0

Initial value "44" adjustment is unnecessary.

Adjustment VR

SBRI

Adjustment Point

————

Input Signal/Setting

It is set in "56".

Adjustment VR

GPOS

Adjustment Point

Connect the oscilloscope to COM output (6PIN of TP1901) and GND.

Input Signal/Setting

Black-and-white 10STEP

Adjustment Method

Adjust the common amplitude to 8.0

±

0.1Vp-p.

8.0

±

0.1Vp-p

Adjustment VR

WB-R

Adjustment Point

Connect the oscilloscope to 3PIN (VG) and 4PIN (VR) of TP1901.

Input Signal/Setting

Black-and-white 10STEP

Adjustment Method

Adjust the white balance (red) so that peak-peak the equal of green and red output become equal.

(2) TV2 adjustment

Adjustment VR

WB-B

Adjustment Point

Dual the oscilloscope to 3PIN (VG) and 5PIN (VB) and GND of TP1901.

Input Signal/Setting

Black-and-white 10STEP

Adjustment Method

Adjust the white balance (blue) so that peak-peak the equal of green and blue output become equal.

Adjustment VR

SCOL

Adjustment Point

Connect the oscilloscope to 5PIN (VB) and GND of TP1901.

Input Signal/Setting

100% color bar

Adjustment Method

Adjust the blue amplitude of the color bar (black level to peak level) to 3.8

±

0.1Vpp.

Adjustment VR

GAM2

Adjustment Point

Connect the oscilloscope to 3PIN (VG) and GND of TP1901.

Input Signal/Setting

Black-and-white 10STEP

Adjustment Method

Adjust the Vpp of VG to 4.3

±

0.1Vp-p.

4.3

±

0.1Vp-p

Adjustment VR

CONT

Adjustment Point

Connect the oscilloscope to 3PIN (VG) and GND of TP1901.

Input Signal/Setting

Black-and-white 10STEP

Adjustment Method

Adjust the Vpp of VG to 3.3Vp-p.

3.3

±

0.1Vp-p

White level

Black level

Sync.

11

DV-L70S

DV-L70BL

DV-L70W

Adjustment VR

STIN

Adjustment Point

Connect the oscilloscope to 5PIN (VB) and GND of TP1901.

Input Signal/Setting

100% color bar

Adjustment Method

It is adjusted so that shakes of the waveform of the blue signal of the color bar may become the

smallest.

(3) TV3 adjustment

Adjustment VR

COM

Adjustment Point

Specified adjustment jig (illuminometer) or visual observation

Input Signal/Setting

No input state

Brightness: Center

Perform it in a combination of PWB and the liquid crystal panel which will be supplied as

products finally.

Brightness: Center

Perform it in a combination of PWB and the liquid crystal panel which will be supplied as

products finally.

Adjustment Method

• When using the specified adjustment jig

Connect the output of jig to the oscilloscope and

adjust the waveform to the minimum point.

At this time, perform the adjustment several times

to fix the optimal point because the measuring value

hardly changes around the optimal point.

Connect the output of jig to the oscilloscope and

adjust the waveform to the minimum point.

At this time, perform the adjustment several times

to fix the optimal point because the measuring value

hardly changes around the optimal point.

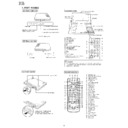

• In case of visual adjustment

Stand or tilt the panel as shown in the figure and check

by shaking your head and seeing whether stripes appear.

If the adjustment is improper, you will see stripes in the

longitudinal direction. Perform the adjustment so that they

do not appear.

Stand or tilt the panel as shown in the figure and check

by shaking your head and seeing whether stripes appear.

If the adjustment is improper, you will see stripes in the

longitudinal direction. Perform the adjustment so that they

do not appear.

(Type drawing)

Optimal point

Adjust within the above

range to fix the optimal point

range to fix the optimal point

Direction of stripe

Adjustment VR

OSDH

Adjustment Point

Visual observation

Adjustment method

Adjust the OSDH of TV3 to 27 mm from the right of screen.

27mm

B brightness

Adjustment VR

B BRI

Adjustment method

Set the B brightness to “76”.

Adjustment VR

OPT adjustment

Initialization

It is set respectively in WIDE "03", OSDV"00", BL"01", PAL"00".

2. OPT adjustment

3. BAR adjustment

Adjustment VR

BAT adjustment

Initialization

Stabilized power supply, in the body, connection.

It is made DVD start rise state, and a BACKLIGHT(HI/LOW/OFF) key is pushed and made "HI".

The voltage of the stabilized power supply is adjusted to become 6.4

±

0.05V in the stabilized

power supply connection part (at DC JACK).

Adjustment Method

It is set so that the numerical value of the BAT display may become "00"

Display