Sharp XL-35 (serv.man9) Service Manual ▷ View online

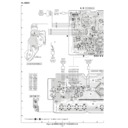

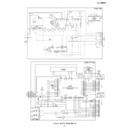

– 7 –

XL-35H

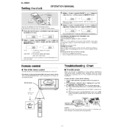

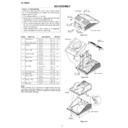

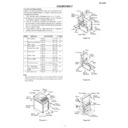

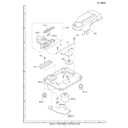

How to remove the pickup (See Fig. 7-3)

1. Remove the mechanism cover, paying attention to the

pawls (A1) x 4 pcs.

2. Remove the screws (A2) x 2 pcs., to remove the shaft (A3)

x 1 pc.

3. Remove the stop washer (A4) x 1 pc., to remove the gear

(A5) x 1 pc.

4. Remove the pickup.

CD MECHANISM SECTION

Perform steps 1, 9 and 10 of the disassembly method to

remove the CD mechanism. (See page 5.)

remove the CD mechanism. (See page 5.)

Pickup Unit

(A2) x2

ø2.6 x6mm

ø2.6 x6mm

(A1) x2

CD Mechanism

Shaft

(A3) x1

(A3) x1

Gear

(A5) x1

(A5) x1

StopWasher

(A4) x1

(A4) x1

Mechanism Cover

(A1) x2

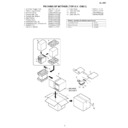

How to remove the tape mechanism PWB

(See Fig. 7-2.)

(See Fig. 7-2.)

1. Remove the screw (F1) x 1 pc., to remove the tape

mechanism PWB.

2. Remove the screws (F2) x 1 pc.

3. Remove the solder joints (F3) x 2 pcs., to remove the tape

3. Remove the solder joints (F3) x 2 pcs., to remove the tape

mechanism PWB.

How to remove the flywheel (See Fig. 7-1.)

1. Remove the belt.

2. Remove the stop washer (E1) x 1 pc., with a small precision

2. Remove the stop washer (E1) x 1 pc., with a small precision

screwdriver to extract the flywheel from the capstan metal.

Note:

When the stop washer is deformed or damaged, replace it

with a new one.

When the stop washer is deformed or damaged, replace it

with a new one.

How to reinstall the parts

Install each part in the reverse order of the removal with care.

Stop

Washer

Washer

Driver

(E1)x1

Stop Washer

Stop Washer

Mechanism

Chassis

Chassis

Washerx2

Flywheel

Tape

Mechanism

PWB

Mechanism

PWB

Tape

Mechanism

PWB

Mechanism

PWB

(F3)x2

Solder

Joint

Solder

Joint

(F2)x1

ø2x8mm

ø2x8mm

(F1)x1

ø2x3mm

ø2x3mm

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

Figure 7-1

Figure 7-2

Figure 7-3

– 7 –

XL-35H

How to remove the pickup (See Fig. 7-3)

1. Remove the mechanism cover, paying attention to the

pawls (A1) x 4 pcs.

2. Remove the screws (A2) x 2 pcs., to remove the shaft (A3)

x 1 pc.

3. Remove the stop washer (A4) x 1 pc., to remove the gear

(A5) x 1 pc.

4. Remove the pickup.

CD MECHANISM SECTION

Perform steps 1, 9 and 10 of the disassembly method to

remove the CD mechanism. (See page 5.)

remove the CD mechanism. (See page 5.)

Pickup Unit

(A2) x2

ø2.6 x6mm

ø2.6 x6mm

(A1) x2

CD Mechanism

Shaft

(A3) x1

(A3) x1

Gear

(A5) x1

(A5) x1

StopWasher

(A4) x1

(A4) x1

Mechanism Cover

(A1) x2

How to remove the tape mechanism PWB

(See Fig. 7-2.)

(See Fig. 7-2.)

1. Remove the screw (F1) x 1 pc., to remove the tape

mechanism PWB.

2. Remove the screws (F2) x 1 pc.

3. Remove the solder joints (F3) x 2 pcs., to remove the tape

3. Remove the solder joints (F3) x 2 pcs., to remove the tape

mechanism PWB.

How to remove the flywheel (See Fig. 7-1.)

1. Remove the belt.

2. Remove the stop washer (E1) x 1 pc., with a small precision

2. Remove the stop washer (E1) x 1 pc., with a small precision

screwdriver to extract the flywheel from the capstan metal.

Note:

When the stop washer is deformed or damaged, replace it

with a new one.

When the stop washer is deformed or damaged, replace it

with a new one.

How to reinstall the parts

Install each part in the reverse order of the removal with care.

Stop

Washer

Washer

Driver

(E1)x1

Stop Washer

Stop Washer

Mechanism

Chassis

Chassis

Washerx2

Flywheel

Tape

Mechanism

PWB

Mechanism

PWB

Tape

Mechanism

PWB

Mechanism

PWB

(F3)x2

Solder

Joint

Solder

Joint

(F2)x1

ø2x8mm

ø2x8mm

(F1)x1

ø2x3mm

ø2x3mm

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

Figure 7-1

Figure 7-2

Figure 7-3

– 7 –

XL-35H

How to remove the pickup (See Fig. 7-3)

1. Remove the mechanism cover, paying attention to the

pawls (A1) x 4 pcs.

2. Remove the screws (A2) x 2 pcs., to remove the shaft (A3)

x 1 pc.

3. Remove the stop washer (A4) x 1 pc., to remove the gear

(A5) x 1 pc.

4. Remove the pickup.

CD MECHANISM SECTION

Perform steps 1, 9 and 10 of the disassembly method to

remove the CD mechanism. (See page 5.)

remove the CD mechanism. (See page 5.)

Pickup Unit

(A2) x2

ø2.6 x6mm

ø2.6 x6mm

(A1) x2

CD Mechanism

Shaft

(A3) x1

(A3) x1

Gear

(A5) x1

(A5) x1

StopWasher

(A4) x1

(A4) x1

Mechanism Cover

(A1) x2

How to remove the tape mechanism PWB

(See Fig. 7-2.)

(See Fig. 7-2.)

1. Remove the screw (F1) x 1 pc., to remove the tape

mechanism PWB.

2. Remove the screws (F2) x 1 pc.

3. Remove the solder joints (F3) x 2 pcs., to remove the tape

3. Remove the solder joints (F3) x 2 pcs., to remove the tape

mechanism PWB.

How to remove the flywheel (See Fig. 7-1.)

1. Remove the belt.

2. Remove the stop washer (E1) x 1 pc., with a small precision

2. Remove the stop washer (E1) x 1 pc., with a small precision

screwdriver to extract the flywheel from the capstan metal.

Note:

When the stop washer is deformed or damaged, replace it

with a new one.

When the stop washer is deformed or damaged, replace it

with a new one.

How to reinstall the parts

Install each part in the reverse order of the removal with care.

Stop

Washer

Washer

Driver

(E1)x1

Stop Washer

Stop Washer

Mechanism

Chassis

Chassis

Washerx2

Flywheel

Tape

Mechanism

PWB

Mechanism

PWB

Tape

Mechanism

PWB

Mechanism

PWB

(F3)x2

Solder

Joint

Solder

Joint

(F2)x1

ø2x8mm

ø2x8mm

(F1)x1

ø2x3mm

ø2x3mm

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

Figure 7-1

Figure 7-2

Figure 7-3

– 7 –

XL-35H

How to remove the pickup (See Fig. 7-3)

1. Remove the mechanism cover, paying attention to the

pawls (A1) x 4 pcs.

2. Remove the screws (A2) x 2 pcs., to remove the shaft (A3)

x 1 pc.

3. Remove the stop washer (A4) x 1 pc., to remove the gear

(A5) x 1 pc.

4. Remove the pickup.

CD MECHANISM SECTION

Perform steps 1, 9 and 10 of the disassembly method to

remove the CD mechanism. (See page 5.)

remove the CD mechanism. (See page 5.)

Pickup Unit

(A2) x2

ø2.6 x6mm

ø2.6 x6mm

(A1) x2

CD Mechanism

Shaft

(A3) x1

(A3) x1

Gear

(A5) x1

(A5) x1

StopWasher

(A4) x1

(A4) x1

Mechanism Cover

(A1) x2

How to remove the tape mechanism PWB

(See Fig. 7-2.)

(See Fig. 7-2.)

1. Remove the screw (F1) x 1 pc., to remove the tape

mechanism PWB.

2. Remove the screws (F2) x 1 pc.

3. Remove the solder joints (F3) x 2 pcs., to remove the tape

3. Remove the solder joints (F3) x 2 pcs., to remove the tape

mechanism PWB.

How to remove the flywheel (See Fig. 7-1.)

1. Remove the belt.

2. Remove the stop washer (E1) x 1 pc., with a small precision

2. Remove the stop washer (E1) x 1 pc., with a small precision

screwdriver to extract the flywheel from the capstan metal.

Note:

When the stop washer is deformed or damaged, replace it

with a new one.

When the stop washer is deformed or damaged, replace it

with a new one.

How to reinstall the parts

Install each part in the reverse order of the removal with care.

Stop

Washer

Washer

Driver

(E1)x1

Stop Washer

Stop Washer

Mechanism

Chassis

Chassis

Washerx2

Flywheel

Tape

Mechanism

PWB

Mechanism

PWB

Tape

Mechanism

PWB

Mechanism

PWB

(F3)x2

Solder

Joint

Solder

Joint

(F2)x1

ø2x8mm

ø2x8mm

(F1)x1

ø2x3mm

ø2x3mm

Note:

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

After removing the connector for the optical pickup from the

connector, wrap the conductive aluminium foil around the

front end of connector remove to protect the optical pickup

from electrostatic damage.

Figure 7-1

Figure 7-2

Figure 7-3

Display