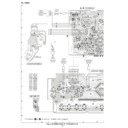

Sharp XL-1500 (serv.man4) Service Manual ▷ View online

– 37 –

XL-1500H

Make sure that the disc is normal, and set the CD TEST MODE (STEP 1).

Is the measured voltage as specified in circuit diagram?

Check the main unit power supply circuit.

No

Yes

No

Is "Er-CD01" displayed"?

Yes

Move the pickup to most internal circumference side of disc.

Turn the power off and reset the CD TEST MODE (STEP 1).

Is "PU ERROR " not displayed?

Turn the power off and reset the CD TEST MODE (STEP 1).

Is "PU ERROR " not displayed?

Yes

Check the PWB pattern between pin 65 (CD_RES) of IC701 and

pin 63 (RST) of IC801.

pin 63 (RST) of IC801.

No

Is +5V applied to pin 63 (RST) of IC801?

Yes

Is CD Lid switch SW802

ON condition ?

ON condition ?

No

Does the CD TEST MODE advance from "STEP 2"?

Yes

Check the between pattern IC701 and SW802 If OK.

Check the main unit power supply circuit.

Check the main unit power supply circuit.

No

Does the laser come on in CD TEST MODE "STEP 2"?

Check the procedure in "LASER FAILURE".

Yes

Does the CD TEST MODE advance from "STEP 3" to "STEP

4"?

4"?

Check the procedure in "FOCUS FAILURE".

Yes

Yes

Does the spindle motor rotate normally when the CD TEST

MODE changes from "STEP 4" to "STEP 3"?

MODE changes from "STEP 4" to "STEP 3"?

Yes

Is the HF output on pin 24 of IC801 in CD TEST MODE "STEP 5"?

Check the procedure "HF ERROR".

Yes

No

No

No

No

Check the pattern between pin 58 (PU_IN) of IC701 and

CNW704/CNP704.

Check the between CNW704/CNP704 and PU-IN switch.

CNW704/CNP704.

Check the between CNW704/CNP704 and PU-IN switch.

Set ON condition the CD

Lid switch.

Lid switch.

Check the procedure in "SPINDLE MOTOR CLV SERVO

FAILURE".

FAILURE".

No

Does the sled motor

move ?

move ?

No

Does the sound heard when the optical pickup move to the

selected play by the FF

selected play by the FF

/REW

key.

Check the procedure "NO SOUND"

No

Yes

Check the procedure in

"SLED MOTOR

OPERATING FAILURE ".

"SLED MOTOR

OPERATING FAILURE ".

Does the LCD track number and time indicator work properly ?

Check the pattern between IC701 and LCD701.

Yes

No

Is "Er-CD01 "

displayed ?

displayed ?

No

Turn the power off and then back on.

Does the unit initialize properly and start playback when PLAY

key is pressed?

Does the unit initialize properly and start playback when PLAY

key is pressed?

Check the pattern between pin 58 (PU_IN) of IC701

and CNW704/CNP704. Check the between CNW704/

CNP704 and PU-IN switch.

and CNW704/CNP704. Check the between CNW704/

CNP704 and PU-IN switch.

No

Yes

Check the procedure in

"HF ERROR".

"HF ERROR".

Yes

Does the unit play in order in the FF mode?

Check the procedure in "TRACK SEARCH FAILUR".

Yes

Does playback continue for 30 seconds after the start of

playback ?

playback ?

Check the procedure in "SLED SERVO FAILURE".

Yes

Normal

No

No

Yes

XL-1500H

– 38 –

Check the PWB pattern between emiter of Q605 and CNP805/

CNW805.

CNW805.

• Laser failure.

Is 0V applied to the pin 38 (SEL) of IC801 ?

Yes

No

Does the laser come on when pattern cut between pin 8 (SEL) of

IC802 and pin 38 (SEL) of IC801 ?

IC802 and pin 38 (SEL) of IC801 ?

Check the PWB pattern between IC701 and IC801 (BUCK/CCE/

BUS0~3)

BUS0~3)

Yes

Yes

No

Check the peripheral parts of IC802 and Q801. If it is normal, the

optical pickup is faulty.

optical pickup is faulty.

No

Check CNP801/CNW801. If it is normal, the optical pickup is

faulty.

faulty.

Is approx. 2V applied to the collector of Q801.

• Focus failure.

Does the optical pickup move up and down when the disc is

removed?

removed?

Is the following waveform ouput at the pin 29 (FEI) of IC801

when the disc is set?

when the disc is set?

Is the waveform shown above input at the pin 30 (SBAD) of

IC801?

IC801?

Yes

Yes

No

No

The optical pickup is faulty.

Check as stated in item "FOCUS SERVO SAWTOOTH WAVE

FAILURE".

FAILURE".

Yes

Check the periphery of IC802 and CNP801/CNW801. Is it normal?

No

Check the pattern between pin 12 of IC802 and pin 30 of IC801.

Check the periphery of IC802 and CNP801/CNW801.

Check the periphery of IC802 and CNP801/CNW801.

IC802 is faulty.

Yes

Is +7.2V applied to the pin 1 of CNW805 ?

Is +5V applied to the cathode side of ZD801 ?

Yes

No

No

Check the peripheral parts of ZD801,C802 and C821.

Is +5V applied to the pin 64 (VDD) of IC801 ?

Is +3.3V applied to the pin 1 (VCC) of IC802 ?

Yes

No

No

Check the PWB pattern between cathode side of ZD801 and pin

64 of IC801.

64 of IC801.

Check the PWB pattern between collector of Q802 and pin 1 of

IC802.

IC802.

pin 29

(FEI)

pin 33

(FOO)

pin 30

(SBAD)

Yes

Yes

– 39 –

XL-1500H

• Focus servo sawtooth wave failure.

Is +7.0V applied to the pins 21 and 22 (VCC) of IC803 ?

Is sawtooh wave output to the pin 33 (FOO) of IC801 ?

IC801 is faulty.

No

Yes

Yes

Is sawtooth wave obtained between pins 17 and 18 of IC803 ?

No

No

Check the PWB pattern

between pin 7 of IC803

and pin 66 (CD STB) of

IC701.

between pin 7 of IC803

and pin 66 (CD STB) of

IC701.

Is +5V applied to the pin 7

(MUTE) of IC803 ?

(MUTE) of IC803 ?

Check the PWB pattern between pin 33 (FOO) of IC801 and pins

19 and 20 of IC803. If OK. IC803 is faulty.

19 and 20 of IC803. If OK. IC803 is faulty.

Check the PWB pattern between pin emiter of Q605 and IC803.

No

Is sawtooth wave obtained between pins 13 and 16 of

CNP801/CNW801 ? (as shown above)

CNP801/CNW801 ? (as shown above)

Yes

Check the PWB pattern between CNP801/CNW801 and IC803.

No

CNP801/CNW801 connection failure or optical pickup failure.

Yes

• Spindle motor clv servo failure.

Is above wave obtained between pins 1 and 2 of IC803 ?

Is following wave output to the pin 41 (DMO) of IC801 when

the CD TEST MODE "STEP 3" is changed to " STEP 4" ?

the CD TEST MODE "STEP 3" is changed to " STEP 4" ?

No

Yes

Check the procedure in "HF ERROR".

If OK. IC801 is faulty.

If OK. IC801 is faulty.

Check the PWB pattern between pin 41 (DMO) of IC801 and pins

9 and 10 of IC803. If OK. IC803 is faulty.

9 and 10 of IC803. If OK. IC803 is faulty.

No

Is above wave obtained between pins 9 and 12 of CNP801/

CNW801 ?

CNW801 ?

Yes

Check the PWB pattern between CNP801/CNW801 and IC803.

No

CNP801/CNW801 connection failure or optical pickup failure.

Yes

DMO

Yes

1.5~2.5sec

1.5~2.5sec

XL-1500H

– 40 –

• HF error.

Yes

Yes

Is output (tracking error signal) obtained at the pins 31 (TEI)

and 32 (TEZI) of IC801 the CD TEST MODE "STEP 4" is

changed to "STEP 5"?

and 32 (TEZI) of IC801 the CD TEST MODE "STEP 4" is

changed to "STEP 5"?

Is output (HF signal) obtained at the pin 24 (RFI) of IC801

when the CD TEST MODE "STEP 4" is changed to "STEP 5"?

when the CD TEST MODE "STEP 4" is changed to "STEP 5"?

Is output (HF signal) obtained at the pins 27 (RFZI) and 28

(RFRP) of IC801 when the CD TEST MODE "STEP 4" is

changed to "STEP 5"?

(RFRP) of IC801 when the CD TEST MODE "STEP 4" is

changed to "STEP 5"?

No

No

• No sound.

No sound from both L and R-ch?

Yes

Is +3.3V applied to pin 51 (DVDD) of IC801?

No

Check the PWB pattern between pin 34 (TRO) of IC801 and pin 25

of IC803.

Check the periphery of IC803 and CNP801/CNW801.

If OK. Optical pickup failure.

of IC803.

Check the periphery of IC803 and CNP801/CNW801.

If OK. Optical pickup failure.

Check the periphery of IC802.

Check the PWB pattern between pin17 (RFRP) of IC802 and pins

27 (RFZI) and 28 (RFRP) of IC801.

If OK. IC802 is faulty.

Check the PWB pattern between pin17 (RFRP) of IC802 and pins

27 (RFZI) and 28 (RFRP) of IC801.

If OK. IC802 is faulty.

No

Yes

Normal.

Check the interval between the pins 50 or 53 of IC801 and the pins

2 or 5 of IC101.

2 or 5 of IC101.

No

Check the PWB pattern between pin 51 of IC801 and Q808.

Yes

Is signal of pins 50 and 53 of IC801 output?

No

Check the peripheral parts of IC801. If OK, IC801 is faulty.

Yes

The main PWB is faulty.

Check the periphery of IC802.

Check the PWB pattern between

pin 11 (TEO) of IC802 and pins 31

and 32 of IC801.

Is it normal ?

Check the PWB pattern between

pin 11 (TEO) of IC802 and pins 31

and 32 of IC801.

Is it normal ?

Is output obtained at the pins 3 and

8 of CNP801/CNW801.

8 of CNP801/CNW801.

Optical pickup failure.

IC802 is faulty.

Check the periphery of IC802.

Check the PWB pattern between pin 19 (RFGO) of IC802 and pins

24 (RFI) of IC801.

If OK. IC802 is faulty

Check the PWB pattern between pin 19 (RFGO) of IC802 and pins

24 (RFI) of IC801.

If OK. IC802 is faulty

Is output obtained at the pins 4 and

5,6 of CNP801/CNW801.

5,6 of CNP801/CNW801.

Optical pickup failure.

Is the following wave output to the pin 41 (DMO) of IC801

when the CD TEST MODE "STEP 4" or "STEP 5"?

when the CD TEST MODE "STEP 4" or "STEP 5"?

Check the periphery pins 15~19 of IC801.

If OK. IC801 failure.

If OK. IC801 failure.

No

No

No

Yes

Yes

No

Yes

Yes

test mode "step 4"

test mode "step 5"

TEI

TEZI

test mode "step 4"

test mode "step 5"

RFI

test mode "step 4"

test mode "step 5"

RFZI

RFRP

test mode "step 4"

test mode "step 5"

DMO