Sharp SD-EX100H (serv.man6) Service Manual ▷ View online

SD-EX100H

– 8 –

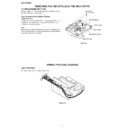

REMOVING AND REINSTALLING THE MAIN PARTS

How to remove the Optical Pickup

(See Fig. 8-1)

(See Fig. 8-1)

1. Remove the stop washer (A1) x 1 pc and gear (A2) x 1 pc.

2. Remove the screws (A3) x 2 pcs and shaft (A4) x 1 pc.

3. Remove the optical pickup.

2. Remove the screws (A3) x 2 pcs and shaft (A4) x 1 pc.

3. Remove the optical pickup.

Note:

After pulling out the optical pickup connector, wrap the tip of

it with conductive aluminium foil or the like to protect the optical

pickup from the static electricity.

After pulling out the optical pickup connector, wrap the tip of

it with conductive aluminium foil or the like to protect the optical

pickup from the static electricity.

Figure 8-1

Optical Pickup

(A3)x2

ø2.6x6mm

ø2.6x6mm

CD Mechanism

Shaft (A4)x1

Gear (A2)x1

Stop Washer (A1)x1

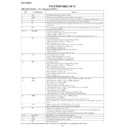

WIRING PROCESS DIAGRAM

1-BIT SECTION

Figure 8-2

CD MECHANISM SECTION

Perform steps 1 to 15 of the disassembly method to remove

the CD mechanism. (See page 5.)

the CD mechanism. (See page 5.)

Tie nylon straps around cords as illustrated.

– 9 –

SD-EX100H

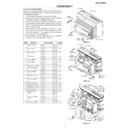

EXPLANATION OF CD MECHANISM

Description of CD Mechanism

This is a vertical loading mechanism, which carries a CD to the playback point. Direct and reverse motors, equipped with the end

detection switches, control the CDs’ movement.

detection switches, control the CDs’ movement.

Opening/closing the tray: CD up/down mechanism

The mechanism carries a CD loaded in the tray to the playback point.

Since the center position differs between 8-cm and 12-cm discs, the tray is positioned by the photo sensor.

The sensor on the right of the slot detects the 12-cm disc.

The mechanism carries a CD loaded in the tray to the playback point.

Since the center position differs between 8-cm and 12-cm discs, the tray is positioned by the photo sensor.

The sensor on the right of the slot detects the 12-cm disc.

Moving up/down the CD mechanism unit: back and forth mechanism

The mechanism moves the unit back and forth to load the medium on or unload the medium from the turntable.

When the mechanism is moved toward the front of the unit, the medium is loaded on the mechanism.

The mechanism moves the unit back and forth to load the medium on or unload the medium from the turntable.

When the mechanism is moved toward the front of the unit, the medium is loaded on the mechanism.

Tray position and waveform

The both end switches and the photo sensor are used for detecting the tray position.

The plate with slits for position detection passes between photo interrupters located on the reverse side of the tray.

The plate with slits for position detection passes between photo interrupters located on the reverse side of the tray.

Open END SW

Open END SW

Close END SW

Close END SW

Light receiving element

Light emitting element

Light receiving element

Light emitting element

Open END SW

Eject END

Close END SW

Position sensor

< Open >

< Close >

12cm Disc Sensor

8cm

Loading position

Loading position

12cm

Loading position

Load END

Tray opened

Photo interrupter

Tray closed

Output waveform when the tray travels

Detecting a 12-cm disc

A CD on the tray passes between the photo interrupters. The signal is not detected when no CDs or an 8-cm CD is loaded.

SD-EX100H

– 10 –

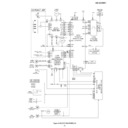

Control Input/Output

The following terminals are used for control.

Microcomputer input terminal

Microcomputer output terminal

Name

Type

Descriptions

SW_Tray Eject

H/L

Switch input for tray eject completion detection

L: Position "Ejected"

H: other positions

H: other positions

SW_Tray Load

H/L

Switch input for tray loading completion detection

L: Position "Loaded"

H: other positions

H: other positions

SW_Mecha Up

H/L

Switch input for mechanism up completion detection

L: "UpEnd" position

H: other positions

H: other positions

SW_Mecha Down

H/L

Switch input for mechanism down completion detection

L: "DownEnd" position

H: other positions

H: other positions

PH_12cm Disc

H/L

Input of the photo sensor for detecting a 12-cm disc. The sensor detects the disc directly.

At the detection position, L : 12-cm disc

At the detection position, L : 12-cm disc

H : Others (interpreted as 8-cm disc)

PH_Tray

H/L

Input of the photo sensor for detecting the tray position. The tray is covered with a piece of tape.

L: a covered tray

H: a non-covered tape. Parts not covered, or a slit.

H: a non-covered tape. Parts not covered, or a slit.

Sens_Jaming

A/Din

Port for overcurrent detection of the mechanism up/down motor

Port voltage > 1.65 V: abnormal. Considered as jamming.

Port voltage < 1.65 V: normal.

Port voltage < 1.65 V: normal.

Name

Type

Initial value

Descriptions

TRY_M+

D Aout

0V

Control output for tray control motor CW (EJECT direction)

TRY_M–

D Aout

0V

Control output for tray control motor CCW (LOADING direction)

MECHA_M+

H/L

L

Control output for mechanism up/down control motor CW (upward,

media loaded)

media loaded)

MECHA_M+

H/L

L

Control output for mechanism up/down control motor CCW

(downward, media removed)

(downward, media removed)

=

– 11 –

SD-EX100H

Initializing the mechanism

The mechanism is initialized and checked in the following cases.

1. The power is turned on for the first time after resetting the microcomputer.

2. The mechanism is not in the loading or ejecting completed state when the power is turned on.

1. The power is turned on for the first time after resetting the microcomputer.

2. The mechanism is not in the loading or ejecting completed state when the power is turned on.

Initializing the mechanism

Start

End

Mechanism up

switch

OK?

Close

Open

The tray moves downward until

the close switch is turned on.

the close switch is turned on.

The CD mechanism moves

downward until the switch is

turned on.

downward until the switch is

turned on.

The CD mechanism moves

downward until the switch is

turned on.

downward until the switch is

turned on.

The tray moves upward until

the open switch is turned on.

the open switch is turned on.

The tray moves downward until

the close switch is turned on.

the close switch is turned on.

OK

OK?

OK?

OK

OK

OK?

OK

OK?

OK

NG

Er-CD TA?O0

NG

Er-CD TA?D0

NG

Er-CD TA?C0

The open switch

is checked.

is checked.

The up/down

motor and the

down switch are

checked.

motor and the

down switch are

checked.

NG

Er-CD TA?D0

The up/down

motor and the

down switch are

checked.

motor and the

down switch are

checked.

The tray motor

and the close

switch are

checked.

and the close

switch are

checked.

NG

Er-CD TA?C0

The tray motor

and the close

switch are

checked.

and the close

switch are

checked.

Display