Sharp CD-CH1500 (serv.man2) Service Manual ▷ View online

CD-CH1000/CD-CH1000H/CD-CH1000W/CD-RW5000H/CD-RW5000W/CD-MD3000H/

CD-MD3000W/CD-CH1500/CD-CH1500H/CD-CH1500W/CD-BA3100

CD-MD3000W/CD-CH1500/CD-CH1500H/CD-CH1500W/CD-BA3100

– 2 –

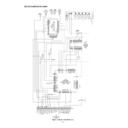

CD CHANGER MECHANISM MAIN BASE PARTS

ASSEMBLING ADJUSTING PROCEDURE

PART NO

PART NAME

MOTOR ASS'Y

01(101)

MAIN BASE

MOUNTING

29(MOB1,2)

MOTOR ASSY x 2

MOTOR

(801)

SCREW x 4

MOTOR GEAR

MT IDLER GEAR

25(137)

MT IDLER GEAR C

MOUNTING

(807)

SCREW x 1

MT SYSTEM GEAR

24(138)

MT IDLER GEAR B

MOUNTING

27(139)

MT IDLER GEAR E

26(140)

MT IDLER GEAR D

23(141)

MT IDLER GEAR A x 2

37(142)

TRAY GEAR C

38(130)

TRAY IDLER GEAR

STB GEAR SHAFT

45(132)

STB GEAR A

47(133-1)

STB GEAR C

(133)

STB GEAR ASSY

48(133-2)

STB GEAR D

(807)

SCREW x 1

46(104)

STB GEAR B

53(105)

STB GEAR ANG

(803)

SCREW x 2

TRAY BIG GEAR

31(134)

TRAY BIG GEAR

GEAR POSITIONING

MOUNTING

T.M SW PWB

MODE SW x 5

TRAY SW x 2

T.M SW PWB ASSY

(PWB-F)

T.M SW PWB ASSY

CABLE HOLDER (8P)

MOUNTING

(802)

SCREW x 2

CAM SW WIRE 8P

(806)

SCREW x 1

STB HOLDER

STB HOLDER ASSEMBLY

MOUNTING

03(147)

STB HOLDER

STBILIZER ASSY

STB DRIVE GEAR

STB DRIVE GEAR L ASSY

STB HOLDER Carefully install them horizontally.

MOUNTING

STB DRIVE GEAR R ASSY

(805)

SCREW x 2

(149)

STABILIZER

(148)

MAGNET

36(125)

TRAY JOINT GEAR R

GEAR POSITIONING

34(124)

TRAY DRIVE GEAR R

TRAY GEAR A/B

32(135)

TRAY GEAR A

GEAR POSITIONING

10(119)

STB DRIVE GEAR A

MOUNTING

33(136)

TRAY GEAR B

11(120)

STB DRIVE GEAR L

(121)

OS LEVER

(123)

OS SPRING

LIFT GEAR B/C

43(128)

LIFT GEAR B

GEAR POSITIONING

(804)

SCREW x 1

ASSEMBLING

44(129)

LIFT GEAR C

41(126)

MODE BIG GEAR

28(131)

MT IDLER GEAR F

(806)

SCREW x 1

10(119)

STB DRIVE GEAR A

12(122)

STB DRIVE GEAR R

(121)

OS LEVER

CHANGE BOX R

04(103)

CHANGE BOX R

(123)

OS SPRING

MOUNTING

(803)

SCREW x 4

(804)

SCREW x 1

LIFT GEAR A

42(127)

LIFT GEAR A

GEAR POSITIONING

Check the gap between the STB DRIVE GEAR L/R and OS LEVER

Check the gap between the STB DRIVE GEAR L/R and OS LEVER

ASSEMBLING

CHANGE BOX L ASSY

CHANGE BOX L ASSY

GEAR POSITIONING

MOUNTING

(803)

SCREW x 4

02(102)

CHANGE BOX L

30(143)

TRAY DRIVE GEAR F

35(144)

TRAY JOINT GEAR F

LIFT CAM

40(115)

LIFT CAM

GEAR POSITIONING

(145)

LIFT LEVER

ASSEMBLING

(116)

LIFT CAM SHAFT

(146)

LIFT LEV SHAFT

(106)

TRAY LOCK LEVER x 6

(107)

TRAY LOCK SPRING

STB HOLDER HIGHT

CHECK/ADJUSTMENT

(802)

SCREW x 3

ADJUSTING

TOP PLATE F

(118)

DISK OB LEV x 2

MOUNTING

80(117)

TOP PLATE F

(803)

SCREW x 6

TRAYS 1-6

91(108)

TRAY 1

ASSEMBLING

92(109)

TRAY 2

93(110)

TRAY 3

94(111)

TRAY 4

15(112)

TRAY 5

96(113)

TRAY 6

TOP PLATE R

(114)

TOP PLATE R

MOUNTING

(803)

SCREW x 6

DISK DETECT SW PWB

DISK DETECT SW x 3

CABLE HOLDER (4P)

CABLE HOLDER (4P)

DISK DETECT SW

DISK DETECT SW PWB ASSY

TRAY SW WIRE 4P

PWB FIXING

(802)

SCREW x 2

CD MECHA

CD MECHA ASSY

FIXING

CD MECHA WIRE

SCREW x 4

CD PWB

CD PWB ASSY

FIXING

SCREW x 4

WIRE DRESS

N-BAND x 2

REMARKS

STB/TRAY DRIVE

SYSTEM GEAR AND

OTHERS ASSY

MOUNTING

MT IDLER GEAR F

ASSEMBLING MODE BIG

GEAR MOUNTING

ASSEMBLING MODE BIG

GEAR MOUNTING

TRAY JOINT GEAR R

/TRAY DRIVE GEAR R

MOUNTING

/TRAY DRIVE GEAR R

MOUNTING

➀

➁

➂

➃

➄

➅

➆

➇

➈

➉

11

12

13

14

15

16

17

18

19

20

21

22

23

24

MOTOR GEAR

ASS'Y

ASS'Y

STB GEAR

T.M SW PWB

STB HOLDER

ASSEMBLY

ASSEMBLY

STABILIZER

ASSEMBLY

STB DRIVE GEAR

L ASS'Y

L ASS'Y

STB DRIVE GEAR

R ASS'Y

R ASS'Y

CHANGE BOX L

ASS'Y

ASS'Y

PWB ASS'Y

CD MECHA

CD PWB

MAIN ASS'Y

ASS'Y

ASS'Y

ASS'Y

ASS'Y

CD-CH1000/CD-CH1000H/CD-CH1000W/CD-RW5000H/CD-RW5000W/CD-MD3000H/

CD-MD3000W/CD-CH1500/CD-CH1500H/CD-CH1500W/CD-BA3100

– 3 –

1. Motor assembly (x 2) mounting (screw x 4).

01/29

Fig. 5

2. MT idle gear mounting (screw x 1).

25

Fig. 5

3. MT system gear assembly.

23/24/26/27

Fig. 5

4. STB/tray drive system gear and others assembling/

37/38/45/46 (53)/47/48

Fig. 5

mounting (screw x 3).

5. Tray big gear assembly.

31

Fig. 5

Gear positioning

6. T.M SW PWB mounting (screw x 3).

Fig. 6

7. STB holder assembling.

03

Fig. 5

8. STB drive gear L/R assembly mounting (screw x 2).

11 (10)/12 (10)

Fig. 5

9. Tray joint gear R/tray drive gear R assembling.

34/36

Fig. 6

Gear positioning

10. Tray gear A/B assembling.

32/33

Fig. 6

Gear positioning

11. Lift gear B/C assembling.

43/44

Fig. 7

Gear positioning

12. MT idler gear F assembling, mode big gear

28/42

Fig. 7

mounting (screw x 1).

13. Change box R mounting (screw x 4).

04

Fig. 7

14. Lift gear A assembling.

42

Fig. 7

Gear positioning

15. Change box L assembly mounting (screw x 4).

02/30/35

Fig. 8

16. Lift cam assembling (shaft inserting).

44

Fig. 8

Gear positioning

17. STB holder height adjusting.

Fig. 9

Check/adjustment

18. Top plate F/disc OB LEV. Mounting (screw x 6).

80

Fig. 9

19. Trays 1 - 6 assembling.

91/92/93/94/95/96

Fig. 10

20. Top plate R mounting (screw x 6).

––

Applied Part No.

Work Content

Assembly Fig. No.

Remarks

CD CHANGER MECHANISM MAIN BASE PARTS ASSEMBLING/ADJUSTING

PROCEDURE

PROCEDURE

01 (101)

MAIN BASE

02 (102)

CHANGE BOX L

03 (147)

STB HOLDER

04 (103)

CHANGE BOX R

10 (119)

STB DRIVE GEAR A

11 (120)

STB DRIVE GEAR L

12 (122)

STB DRIVE GEAR R

20 (149)

STABILIZER FH

23 (141)

MT IDLER GEAR A

24 (138)

MT IDLER GEAR B

25 (137)

MT IDLER GEAR C

26 (140)

MT IDLER GEAR D

27 (139)

MT IDLER GEAR E

28 (131)

MT IDLER GEAR F

29 (MOB1,2)

MOTOR GEAR

30 (143)

TRAY DRIVE GEAR F

31 (134)

TRAY BIG GEAR

32 (135)

TRAY GEAR A

33 (136)

TRAY GEAR B

34 (124)

TRAY DRIVE GEAR R

35 (144)

TRAY JOINT GEAR F

36 (125)

TRAY JOINT GEAR R

37 (142)

TRAY GEAR C

38 (130)

TRAY IDLER GEAR

Part Name

No.

40 (115)

LIFT CAM

41 (126)

MODE BIG GEAR

42 (127)

LIFT GEAR A

43 (128)

LIFT GEAR B

44 (129)

LIFT GEAR C

45 (132)

STB GEAR A

46 (104)

STB GEAR B

47 (133-1)

STB GEAR C

48 (133-3)

STB GEAR D

50 (145)

LIFT LEVER

51 (106)

TRAY LOCK LEVER

52 (118)

DISC OB LEVER

53 (105)

STB GEAR ANG

80 (117)

TOP PLATE F

81 (114)

TOP PLATE R

91 (108)

TRAY 1

92 (109)

TRAY 2

93 (110)

TRAY 3

94 (111)

TRAY 4

95 (112)

TRAY 5

96 (113)

TRAY 6

Part Name

No.

CD CHANGER MECHANISM PARTS LIST

The number of ( ) is the number of the parts guide.

CD-CH1000/CD-CH1000H/CD-CH1000W/CD-RW5000H/CD-RW5000W/CD-MD3000H/

CD-MD3000W/CD-CH1500/CD-CH1500H/CD-CH1500W/CD-BA3100

CD-MD3000W/CD-CH1500/CD-CH1500H/CD-CH1500W/CD-BA3100

– 4 –

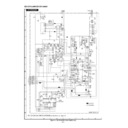

46(104)

45(132)

44(129)

43(128)

42(127)

36(125)

32(135)

30(143)

24(138)

23(141)

TRAY DRIVE GEAR F

TRAY GEAR A

TRAY JOINT GEAR R

LIFT GEAR A

STB GEAR A

STB GEAR B

LIFT GEAR B

LIFT GEAR C

STB DRIVE GEAR A

MT IDLER GEAR A

MT IDLER GEAR B

10(119)

φ

20

d=52.7

φ

27.2

h=12.4

φ

30.4

h=9.5

h=6.3

φ

14

h=5.5

φ

18.4

h=36.5

φ

18.4

h=80.7

h=17.4

φ

16

h=8.2

φ

27

h=25.7

h=8.6

φ

23.7

31(134)

37(142)

33(136)

25(137)

11(120)

TRAY GEAR B

TRAY GEAR C

TRAY BIG GEAR

STB DRIVE GEAR L

MT IDLER GEAR C

38(130)

34(124)

26(140)

TRAY DRIVE GEAR R

MT IDLER GEAR D

TRAY IDLER GEAR

White Color

h=18

φ

20

d=52.7

φ

17

h=26

h=5.6

φ

16

φ

23

h=12.5

h=15

φ

22.2

φ

27.2

h=3.8

35(144)

28(131)

MT IDLER GEAR F

27(139)

12(122)

TRAY JOINT GEAR F

MT IDLER GEAR E

STB DRIVE GEAR R

Black Color

d=52.7

h=21.9

φ

17.6

φ

20.4

h=9.7

41(126)

40(115)

LIFT CAM

MODE BIG GEAR

φ

23

h=75.2

Figure 4

CD-CH1000/CD-CH1000H/CD-CH1000W/CD-RW5000H/CD-RW5000W/CD-MD3000H/

CD-MD3000W/CD-CH1500/CD-CH1500H/CD-CH1500W/CD-BA3100

– 5 –

Figure 5

03

STB HOLDER

STB HOLDER

48

STB GEAR D

STB GEAR D

12

STB DRIVE GEAR R

(ASSY)

10

STB DRIVE GEAR A

29

29

23

23

24

25

26

27

01

MAIN BASE

MAIN BASE

Mark position

After assembling TRAY BIG GEAR, turn it in the arrow direction.

TRAY BIG GEAR ASSEMBLING POSITION

31

TRAY BIG GEAR

TRAY BIG GEAR

37

TRAY GEAR C

TRAY GEAR C

38

TRAY IDLER GEAR

TRAY IDLER GEAR

47

STB GEAR C

46

STB GEAR B

10

STB DRIVE GEAR A

11

STB DRIVE GEAR L

(ASSY)

53

STB GEAR ANG.

45

STB GEAR A

11(/12) (10)

STB DRIVE GEAR L(/R)

(ASS'Y)

STB DRIVE GEAR L(/R)

(ASS'Y)

46

STB GEAR B

37

TRAY GEAR C

TRAY GEAR C

47

STB GEAR C

31

TRAY BIG GEAR

38

TRAY IDLER GEAR

45

STB GEAR A

53

STB GEAR ANG.

L