Sharp CD-C621H (serv.man12) Service Manual ▷ View online

– 43 –

CD-C621H

FUNCTION TABLE OF IC

IC1 VHiLA9241M/-1: Servo Amp. (LA9241M) (1/2)

1

FIN2

Connection pin for photodiode of pickup.

RF signal is generated through addition with FIN pin, and FE signal is generated through subtraction.

RF signal is generated through addition with FIN pin, and FE signal is generated through subtraction.

2

FIN1

Connection pin for photodiode of pickup.

3

E

Connection pin for photodiode of pickup. TE signal is generated through subtraction with F pin.

4

F

Connection pin for photodiode of pickup.

5

TB

Pin for input of DC component of TE signal.

6

TE-

Pin to connect gain setting resistor of TE signal to TE signal.

7

TE

TE signal output pin.

8

TESI

TES (Track error sense) comparator input pin. TE signal is band-passed and input.

9

SCI

Input pin for shock detection.

10

TH

Pin to set time constant of tracking gain.

11*

TA

TA amplifier output pin.

12

TD-

Pin to compose tracking phase compensation constant between TD and VR pins.

13

TD

Pin to set tracking phase compensation.

14

JP

Pin to set amplitude of tracking jump signal (kick pulse).

15

TO

Tracking control signal output pin.

16

FD

Focusing control signal output pin.

17

FD-

Pin to compose focusing phase compensation constant between FD and FA pins.

18

FA

Pin to compose focusing phase compensation constant between FD-/FA-pins.

19

FA-

Pin to compose focusing phase compensation constant between FA and FE pins.

20

FE

Output pin of FE signal.

21

FE-

Pin to connect gain setting resistor of FE signal across TE pin.

22

AGND

GND for analog signal.

23

NC

No connect.

24

SPI

Spindle amplifier input.

25

SPG

Pin to connect gain setting resistor in the 12cm mode of spindle.

26

SP-

Pin to connect spindle phase compensation constant together with SPD pin.

27

SPD

Spindle control signal output pin.

28

SLEQ

Pin to connect thread phase compensation constant.

29

SLD

Thread control signal output pin.

30

SL-

Input pin of thread feed signal from micro computer.

31

SL+

Input pin of thread feed signal from micro computer.

32

JP-

Input pin of tracking jump signal from DSP.

33

JP+

Input pin of tracking jump signal from DSP.

34

TGL

Input pin of tracking gain control signal from DSP. TGL = Gain low at "H"

35

TOFF

Input pin of tracking off control signal from DSP. TOFF = Off at "H"

36

TES

Output pin of TES signal to DSP.

37

HFL

(HIGH FREQUENCY LEVEL) is used to judge whether main beam is positioned on the bit or on the mirror.

38

SLOF

Thread servo off control input pin.

39

CV-

Pin to input CLV error signal from DSP.

40

CV+

Pin to input CLV error signal from DSP.

41

RFSM

RF output pin.

42

RFS-

Pin to set gain of RF and set 3T compensation constant together with RFSM pin.

43

SLC

(SLICE LEVEL CONTROL) is the output pin to control of the level of the data slice with RF waveform DSP.

44

SLI

Input pin to control the level of data slice with DSP.

45

DGND

GND pin in the digital system.

46

FSC

Output pin for focus search smoothening capacitor.

47

TBC

(Tracking Balance Control) Pin to set EF balance variable range.

48*

NC

No connect.

49

DEF

Defect detection output pin of disk.

50

CLK

Reference clock input pin. 4.23MHz of DSP is input.

Pin No.

Port Name

Function

In this unit, the terminal with asterisk mark (*) is (open) terminal which is not connected to the outside.

CD-C621H

– 44 –

IC1 VHiLA9241M/-1:Servo Amp.(LA9241M) (2/2)

Pin No.

Port Name

Function

51

CL

Micro computer command clock input pin.

52

DAT

Micro computer command data input pin.

53

CE

Micro computer command chip enable input pin.

54

DRF

(DETECT RF) RF level detection output.

55

FSS

(Focus Serch Select) Pin to switch focus search mode. (

±

search/+ search for reference voltage)

56

VCC2

VCC pin for servo system and digital system.

57

REFI

Pin to connect pass control for reference voltage.

58

VR

Reference voltage output pin.

59

LF2

Pin to set defect detection time constant of disk.

60

PH1

Pin to connect capacitor for peak hold of RF signal.

61

BH1

Pin to connect capacitor for bottom hold of RF signal.

62

LDD

APC circuit output pin.

63

LDS

APC circuit output pin.

64

VCC1

RF system VCC pin.

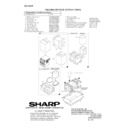

Figure 44 BLOCK DIAGRAM OF IC

1

FIN2

FIN1

E

F

TB

TE-

TE

TESI

SCI

TH

TA

TD-

TD

JP

TO

FD

FD-

FA

FA-

FE

FE- AGND SP

SPI

SPG

SP-

SPD

SLEQ

SLD

SL- SL+

JP-

JP+

TGL

TOFF

TES

HFL

SLOF

CV-

CV+

RFSM

RFS-

SLC

SLI

DGND

FSC

TBC

NC

DEF

CLK

CL

DAT

CE

DRF

FSS

VCC2

REFI

VR

LP2

PH1

BH1

LDD

LDS

SLC

RF AMP

TE

F.SERVO & F.LOGIC

SPINDLE SERVO

SLED SERVO

VCC1

2

3

4

6

7

5

8

9

10

11

12

13

14

15

16

17

18

19

20

21

23

22

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

46

47

48

49

50

51

52

53

54

55

56

57

58

59

61

60

62

63

64

45

24

APC

RF DET

REF

VCA

VCA

INTER FACE

BAL

µ

-COM

I/V

T.SERVO & T.LOGIC

NC

– 45 –

CD-C621H

1

DEFI

Input

Defect detection signal (DFF) input terminal. (When this terminal is not used, connect it to 0V.)

2

TAI

Input

For PLL Input terminal for test. Pull-down resistor built in. Be sure to connect this terminal to 0V.

3

PDO

Output

Phase comparison output terminal for external VCO control.

4

VVSS

—

Grounding terminal for built-in VCO. Be sure to connect this terminal to 0V.

5

ISET

Input

Resistor connection terminal for adjustment of PDO output current.

6

VVDD

—

Power terminal for built-in VCO.

7

FR

Input

For VCO frequency range adjustment.

8

VSS

—

Digital system grounding terminal. Be sure to connect this terminal to 0V.

9

EFMO

Output

For slice level control EFM signal output terminal.

10

EFMIN

Input

EFM signal input terminal.

11

TEST2

Input

Input terminal for test. Pull-down resistor built-in. Be sure to connect this terminal to 0V.

12

CLV+

Outout

Output for disc motor control. 3-value output is enabled according to command.

13

CLV-

Output

Output for disc motor control. 3-value output is enabled according to command.

14

V/P

Output

Rough servo/phase control automatic selection monitor output terminal.

"H": Rough servo, "L": Phase servo

"H": Rough servo, "L": Phase servo

15

HLF

Intput

Track detection signal input terminal. Schmidt input.

16

TES

Input

Tracking error signal input terminal. Schmidt input.

17

TOFF

Output

Tracking OFF output terminal.

18

TGL

Output

Output terminal for tracking gain selection. "L": Gain raising.

19

JP+

Output

Output for track jump control. 3-value output is enabled according to command.

20

JP-

Output

Output for track jump control. 3-value output is enabled according to command.

21*

PCK

Output

Clock monitor terminal for EFM data play-back. Phase lock: 4.3218 MHz.

22*

FSEQ

Output

Sync signal detection output terminal.

When the sync signal detected from the EFM signal coincides with the internally generated sync

signal: "H"

When the sync signal detected from the EFM signal coincides with the internally generated sync

signal: "H"

23

VDD

—

Digital system power terminal.

24

CONT1

Input/Output General-use input/output terminal 1.

25

CONT2

Input/Output General-use input/output terminal 2.

26

CONT3

Input/Output General-use input/output terminal 3.

27

CONT4

Input/Output General-use input/output terminal 4.

28*

CONT5

Input/Output General-use input/output terminal 5.

29*

EMPH/CONT6

Output

Deemphasis monitor terminal. "H": Deemphasis disc play-back. General-use output terminal 6.

30*

C2F

Output

C2 flag output terminal.

31*

DOUT

Output

Digital OUT output terminal. (EIAJ format)

32*

TEST3

Input

Input terminal for test. Pull-down resistor built-in. Be sure to connect this terminal to 0V.

33

TEST4

Input

Input terminal for test. Pull-down resistor built-in. Be sure to connect this terminal to 0V.

34

PCCL

Input

General-use input/output command recognition terminal. Pull-down resistor built in.

When this terminal is used for the same function as that of LC78622E, open or connect this

terminal to 0V.

H: Only the general-use input/output port command is controllable.

L: All command controls are enabled.

When this terminal is used for the same function as that of LC78622E, open or connect this

terminal to 0V.

H: Only the general-use input/output port command is controllable.

L: All command controls are enabled.

35*

MUTEL/CONT7

Output

L channel 1-bit DAC

Mute output terminal for L channel. General-use output terminal 7.

36

LVDD

—

Power terminal for L channel.

37

LCHO

Output

L channel output terminal.

38

LVSS

—

Grounding terminal for L channel. Be sure to connect this terminal to 0V.

39

RVSS

—

R channel 1-bit DAC

Grounding terminal for R channel. Be sure to connect this terminal to 0V.

40

RCHO

Output

R channel output terminal.

41

RVDD

—

Power terminal for R channel.

42*

MUTER/CONT8

Output

Mute output terminal for R channel. General-use output terminal 8.

43

XVDD

—

Power terminal for crystal oscillation.

44

XOUT

Output

16.9344 MHz crystal oscillator connection terminal.

45

XIN

Input

16.9344 MHz crystal oscillator connection terminal.

46

XVSS

—

Grounding terminal for crystal oscillation. Be sure to connect this terminal to 0V.

IC2 VHiLC78622N-1: Servo/Signal Control (LC78622NE) (1/2)

Pin

No.

No.

Function

Terminal Name Input/Output

Control with serial data command from microcomputer.

When this terminal is not used, set it as an input terminal

and connect to 0V or set it as an output terminal and

open.

When this terminal is not used, set it as an input terminal

and connect to 0V or set it as an output terminal and

open.

In this unit, the terminal with asterisk mark (*) is (open) terminal which is not connected to the outside.

CD-C621H

– 46 –

IC2 VHiLC78622N-1: Servo/Signal Control (LC78622NE) (2/2)

47*

SBSY

Output

Sub-code clock sync signal output terminal.

48*

EFLG

Output

C1, C2, single, double correction monitor terminal.

49*

PW

Output

Sub-code P, Q, R, S, T, U, and W output terminal.

50*

SFSY

Output

Sub-code frame sync signal output terminal. Falling occurs when the sub-code is in standby state.

51

SBCK

Input

Sub-code read clock input terminal. Schmidt input (When this terminal is not used, connect it to 0V.)

52*

FSX

Output

7.35 kHz sync signal (frequency-divided from crystal oscillation) output terminal.

53

WRQ

Output

Sub-code Q output standby output terminal.

54

RWC

Input

Read/Write control input terminal. Schmidt input.

55

SQOUT

Output

Sub-code Q output terminal.

56

COIN

Input

Command input terminal from microcomputer.

57

CQCK

Input

Command input taking-in clock or sub-code taking-out (from SQOUT) clock input terminal.

Schmidt input

Schmidt input

58

RES

Input

LSI resetting input terminal. When power is turned on, once "L" is set.

59*

TEST11

Output

Output terminal for test. Use this terminal in open state (usually "L" output).

60*

16M

Output

16.9344 MHz output terminal.

61

4.2M

Output

4.2336 MHz output terminal.

62

TEST5

Input

Input terminal for test. Pull-down resistor built-in. Be sure to connect this terminal to 0V.

63

CS

Input

Chip selection input terminal. Pull-down resistor built-in.

In noncontrol state connect this terminal to 0V.

In noncontrol state connect this terminal to 0V.

64

TEST1

Input

Input terminal for test. Pull-down resistor is not provided. Be sure to connect this terminal to 0V.

Note: The same potential must be supplied to the power terminals (VDD, VVDD, LVDD, RVDD, XVDD).

In this unit, the terminal with asterisk mark (*) is (open) terminal which is not connected to the outside.

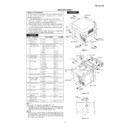

Figure 46 BLOCK DIAGRAM OF IC

Pin

No.

No.

Function

Terminal Name Input/Output

DEFI

EFMIN

FSEQ

V/P

PW

SBCK

SBSY

SFSY

CS

WRQ

SQOUT

COIN

RWC

CQCK

HFL

TES

TOFF

JP-

JP+

RES

TGL

CONT1

PCCL

CONT2

CONT3

CONT4

CONT5

EMPH/CONT6

EFLG

16M

4.2M

XVss

FSX

XIN

XOUT

XV

DD

RVss

RV

DD

MUTER/CONT7

RCHO

LCHO

MUTEL/CONT8

LVss

LV

DD

DOUT

C2F

EFMO

VV

DD

VVss

PDO

I SET

FR

PCK

TAI

TST11

TEST1

TEST2

TEST3

TEST4

TEST5

V

DD

Vss

CLV+

CLV-

Slice level

control

VCO colck oscillation

clock control

2 K x 8 b i t

R A M

RAM address

generator

Interpolation mute

Bilingual

Digital OUT

Digital

attenuator

X4 oversampling

digital filter

1 b i t D A C

L . P . F

XTAL system timing

generator

General-use port

Servo commander

µ

C O M

Interface

Subcode division

QCRC

C L V

Digital servo

Sync detection

EFM demodulation

Flag processing of C1/C2

error detection and correction

Display