Sharp AU-X08 (serv.man15) Service Manual ▷ View online

51

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

AH/AY-X10CR

AH/AY-X13CR

(3) Lubricationg Oils for R410A

As the lubricating oils for R22, mineral oils, alkylbenze synthetic oils, etc. have so far been used. As R410A

features less solubility with these conventional lubricating oils such as mineral oils, the lubricating oils tend

to stay within the refrigeration cycle. As the lubricating oils highly soluble with R410A, ester, ethereal and

other synthetic oils are available. However, as these synthetic oils are very hygroscopic, they must be

treated even more carefully than the conventional lubricating oils. Furthermore, if these synthetic oils are

mixed with mineral oils, alkylbenzene synthetic oils, etc., they may deteriorate, and block the capillary

tubes, or cause the compressor to fail. So, never mix these synthetic oils.

features less solubility with these conventional lubricating oils such as mineral oils, the lubricating oils tend

to stay within the refrigeration cycle. As the lubricating oils highly soluble with R410A, ester, ethereal and

other synthetic oils are available. However, as these synthetic oils are very hygroscopic, they must be

treated even more carefully than the conventional lubricating oils. Furthermore, if these synthetic oils are

mixed with mineral oils, alkylbenzene synthetic oils, etc., they may deteriorate, and block the capillary

tubes, or cause the compressor to fail. So, never mix these synthetic oils.

1.2 Safety during Installation/Servicing

As R410A's pressure is about 1.6 times higher than that of R22, improper installation/servicing may cause a

serious trouble. By using tools and materials exclusive for R410A, it is necessary to carry out installation/servicing

safely while taking the following precautions into consideration.

1) Never use refrigerant other than R410A in an air conditioner which is designed to operate with R410A.

2) If a refrigeration gas leakage occurs during installation/servicing, be sure to ventilate fully.

serious trouble. By using tools and materials exclusive for R410A, it is necessary to carry out installation/servicing

safely while taking the following precautions into consideration.

1) Never use refrigerant other than R410A in an air conditioner which is designed to operate with R410A.

2) If a refrigeration gas leakage occurs during installation/servicing, be sure to ventilate fully.

If the refrigerant gas comes into contact with fire, a poisonous gas may occur.

3) When installing or removing an air conditioner, do not allow air or moisture to remain in the refrigeration cycle.

Otherwise, pressure in the refrigeration cycle may become abnormally high so that a rupture or personal injury

may be caused.

may be caused.

4) After completion of installation work, check to make sure that there is no refrigeration gas leakage.

If the refrigerant gas leaks into the room, coming into contact with fire in the fandriven heater, space heater,

etc., a poisonous gas may occur.

etc., a poisonous gas may occur.

5) When an air conditioning system charged with a large volume of refrigerant (e. g. multi type air conditioner) is

installed in a small room, it is necessary to exercise care so that, even when refrigerant leaks, its concentration

does not exceed the marginal level.

If teh refrigerant gas leakage occurs and its concentration exceeds the marginal level, an oxygen starvation

accident may result.

does not exceed the marginal level.

If teh refrigerant gas leakage occurs and its concentration exceeds the marginal level, an oxygen starvation

accident may result.

6) Be sure to carry out installation or removal according to the installation manual. Improper installation may

cause refrigeration troule, water leakage, electric shock, fire, etc.

7) Unauthorized modifications to the air conditioner may be dangerous. If a breakdown occurs please call a

qualified air conditioner technician or electrician.

Improper repair's may result in water leakage, electric shock and file, etc.

Improper repair's may result in water leakage, electric shock and file, etc.

2. Refrigerant Piping Installation

2.1 Piping Materials and Joints Used

For the refrigerant piping installation, copper pipes and joints are mainly used. Copper pipes and joints suitable for

the refrigerant must be chosen and installed. Furthermore, it is necessary to use clean copper pipes and joints

whose interior surfaces are less affected by contaminants.

the refrigerant must be chosen and installed. Furthermore, it is necessary to use clean copper pipes and joints

whose interior surfaces are less affected by contaminants.

(1) Copper Pipes

It is necessary to use seamless copper pipes which are made of either copper or copper alloy and it is

desirable that the amount of residual oil is less than 40 mg/10m. Do not use copper pipes having a collapsed,

deformed or discolored portion (especially on the interior surface). Otherwise, the expansion valve or capillary

tube may become blocked with contaminants.

As an air conditioner using R410A incurs pressure higher than when using R22, it is necessary to choose

adequate materials.

Thicknesses of copper pipes used with R410A are as shown in Table 3. Never use copper pipes thinner than

0.8 mm even when it is available on the market.

desirable that the amount of residual oil is less than 40 mg/10m. Do not use copper pipes having a collapsed,

deformed or discolored portion (especially on the interior surface). Otherwise, the expansion valve or capillary

tube may become blocked with contaminants.

As an air conditioner using R410A incurs pressure higher than when using R22, it is necessary to choose

adequate materials.

Thicknesses of copper pipes used with R410A are as shown in Table 3. Never use copper pipes thinner than

0.8 mm even when it is available on the market.

Table 3. Thicknesses of Annealed Copper Pipes

Normal diameter

Thicknesses (mm)

Outer diameter (mm)

[ref.] R22

6.35

0.80

9.52

0.80

12.70

0.80

15.88

1.00

R410

0.80

0.80

0.80

1.00

1/4

3/8

1/2

5/8

52

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

AH/AY-X10CR

AH/AY-X13CR

2.2 Processing of Piping Materials

When performing the refrigerant piping installation, care should be taken to ensure that water or dust does

not enter the pipe interior, that no other oil other than lubricating oils used in the installed air conditioner is

used, and that refrigerant does not leak. When using lubricating oils in the piping processing, use such

lubricating oils whose water content has been removed. When stored, be sure to seal the container with an

airtight cap or any other cover.

(1) Flare Processing Procedures and Precautions

not enter the pipe interior, that no other oil other than lubricating oils used in the installed air conditioner is

used, and that refrigerant does not leak. When using lubricating oils in the piping processing, use such

lubricating oils whose water content has been removed. When stored, be sure to seal the container with an

airtight cap or any other cover.

(1) Flare Processing Procedures and Precautions

a) Cutting the Pipe

By means of a pipe cutter, slowly cut the pipe so that it is not deformed.

b) Removing Burrs and Chips

If the flared section has chips or burrs, refrigerant leakage may occur. Carefully remove all burrs and

clean the cut surface before installation.

clean the cut surface before installation.

c) Insertion of Flare Nut

d) Flare Processing

d) Flare Processing

Make certain that a clamp bar and copper pipe have been cleaned.

By means of the clamp bar, perform the flare processing correctly.

Use either a flare tool for R410A or conventional flare tool.

Flare processing dimensions differ according to the type of flare

tool. Be careful. When using a conventional flare tool, be sure to

secure "dimension A" by using a gage for size adjustment.

By means of the clamp bar, perform the flare processing correctly.

Use either a flare tool for R410A or conventional flare tool.

Flare processing dimensions differ according to the type of flare

tool. Be careful. When using a conventional flare tool, be sure to

secure "dimension A" by using a gage for size adjustment.

Table 4. Dimensions related to Flare Processing for R410A

Norminal

diameter

Norminal

diameter

(mm)

A (mm)

Conventional flare tool

Clutch type

Wing nut type

1.5 ~ 2.0

1.5 ~ 2.0

2.0 ~ 2.5

2.0 ~ 2.5

1.0 ~ 1.5

1.0 ~ 1.5

1.0 ~ 1.5

1.0 ~ 1.5

0 ~ 0.5

0 ~ 0.5

0 ~ 0.5

0 ~ 0.5

Flare tool fot R410A

Clutch type

1/4

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

3/8

1/2

5/8

Table 5. Dimensions related to Flare Processing for R22

Norminal

diameter

Norminal

diameter

(mm)

A (mm)

Conventional flare tool

Clutch type

Wing nut type

1.0 ~ 1.5

1.0 ~ 1.5

1.5 ~ 2.0

1.5 ~ 2.0

0.5 ~ 1.0

0.5 ~ 1.0

0.5 ~ 1.0

0.5 ~ 1.0

0 ~ 0.5

0 ~ 0.5

0 ~ 0.5

0 ~ 0.5

Flare tool fot R410A

Clutch type

1/4

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

3/8

1/2

5/8

Table 6. Flare and Flare Nut Dimensions for R410A

Norminal

diameter

Norminal

diameter

(mm)

Dimension (mm)

Flare nut

width

9.1

13.2

16.6

19.7

A

9.2

13.5

16.0

19.0

B

6.5

9.7

12.9

16.0

C

13

17

22

26

29

20

23

25

D

1/4

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

3/8

1/2

5/8

[Unit: mm]

ØD

A

Fig. 3 Flare Processing DImensions

53

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

AH/AY-X10CR

AH/AY-X13CR

Table 7. Flare and Flare Nut Dimensions for R22

Norminal

diameter

Norminal

diameter

(mm)

Dimension (mm)

Flare nut

width

9.0

13.0

16.2

19.4

A

9.2

13.5

16.0

19.0

B

6.5

9.7

12.9

16.0

C

13

17

22

24

27

20

20

23

D

1/4

6.35

9.52

12.70

15.88

Thickness

(mm)

0.8

0.8

0.8

1.0

3/8

1/2

5/8

[Unit: mm]

45

˚ ~ 46

˚

43

˚ ~ 45

˚

B

C

D

A

Fig. 4 Relations between Flare Nut and Flare Seal Surface

(2) Flare Connecting Procedures and Precautions

a) Make sure that the flare and union portions do not have any scar or dust, etc.

b) Correctly align the processed flare surface with the union axis.

c) Tighten the flare with designated torque by means of a torque wrench. The tightening torque for

b) Correctly align the processed flare surface with the union axis.

c) Tighten the flare with designated torque by means of a torque wrench. The tightening torque for

R410A is same as that for conventional R22. Incidentally, when the torque is wekd, the gas leakage

may occur. When it is strong, the flare nut may crack and may be made nonremovable. When

choosing the tightening torque, comply with values designated by manufacturers. Table 9 shows

reference values.

Note:When applying oil to the flare surface, be sure to use oil designated by the manufacturer. If any

other oil is used, the lubricating oils may deteriorate and cause the compressor to burn out.

may occur. When it is strong, the flare nut may crack and may be made nonremovable. When

choosing the tightening torque, comply with values designated by manufacturers. Table 9 shows

reference values.

Note:When applying oil to the flare surface, be sure to use oil designated by the manufacturer. If any

other oil is used, the lubricating oils may deteriorate and cause the compressor to burn out.

Table 8. Tightening Torque of R410A [Reference Values]

Norminal

diameter

Norminal

diameter

(mm)

16 (160), 18 (180)

42 (420)

55 (550)

65 (650)

1/4

6.35

9.52

12.70

15.88

14 ~ 18 (140 ~ 180)

33 ~ 42 (330 ~ 420)

50 ~ 62 (500 ~ 620)

63 ~ 77 (630 ~ 770)

3/8

1/2

5/8

Tightening torque

N m (kgf cm)

Tightening torque of torque

wrenches available on the market

N m (kgf cm)

54

AH/AY-X08CR

AH/AY-X10CR

AH/AY-X13CR

AH/AY-X10CR

AH/AY-X13CR

2.3 Storage of Piping Materials

(1) Types and Storage of Piping Materials

Refrigerant piping materials for air conditioners are broadly classified into the following types.

Refrigerant piping

materials

materials

with heat

insulation

without heat

insulation

(bare copper pipe)

insulation

without heat

insulation

(bare copper pipe)

with flare processing

without flare processing

without flare processing

without flare processing

without flare processing

General name

: (a) Piping set

: (b) Copper pipe with insulation

: (c) Bare copper pipe

: (a) Piping set

: (b) Copper pipe with insulation

: (c) Bare copper pipe

As R410A features pressure about 1.6 times higher than R22, it is necessary to use a copper pipe which has

a thickness stated in Table 3 and which contains less contaminants. It is necessary to carefully treat/store

copper pipes so that they are not collapesd, deformed or damaged. Due care must also be exercised so that

foreign matters such as dust and water do not enter the pipe interior.

copper pipes so that they are not collapesd, deformed or damaged. Due care must also be exercised so that

foreign matters such as dust and water do not enter the pipe interior.

A piping set's open end is sealed with a cap, etc. When storing it, make sure that it is sealed securely. When

storing a cladded copper pipe or bare copper pipe, securely seal the opening with pinching, taping, etc.

(2) Identification

a) Piping set

A copper pipe as piping set for R410A must have a thickness as stated in Table 3, and, as shown in Tables

5 and 6, it also differs from R22 in flare processing and flare nut dimensions. So, it is necessary to choose

a piping set suitable for R410A.

5 and 6, it also differs from R22 in flare processing and flare nut dimensions. So, it is necessary to choose

a piping set suitable for R410A.

b) Copper Pipe with Insulation

Before using a copper pipe with insulation, make sure that is has a thickness designated for R410A.

c) Bare Copper Pipe

It is necessary to use a bare copper pipe which has a thickness desigtnated in Table 3 and contains less

contaminants. As the bare copper pipe surface is naked, it is necessary to treat it with exceeding care and

adopt a means for identification to prevent improper usage by making it easily discriminable from other

piping materials.

contaminants. As the bare copper pipe surface is naked, it is necessary to treat it with exceeding care and

adopt a means for identification to prevent improper usage by making it easily discriminable from other

piping materials.

(3) Precautions before Installation

Observe the following precautions when performing the piping connection at the site.

a) Keep any open ends of pipes be sealed with a cap, etc. until connected with the equipment.

b) Exercise great care when performing piping installation on a rainy day.

a) Keep any open ends of pipes be sealed with a cap, etc. until connected with the equipment.

b) Exercise great care when performing piping installation on a rainy day.

When water enters into the piping, the lubricating oil may deteriorate and cause the equipment to fail.

c) Carry out the piping connection in as short a time as possible.

If the piping is left open for a long period, fully purge the interior with nitrogen gas or dry it with a vacuum

pump.

pump.

3. Installation, Removal and Servicing

3.1 Tools for R410A

In the case of an air conditioner using R410A, in order to prevent any other refrigerant from being

chargedaccidentally, the service port diameter of the outdoor unit control valve (3-way valve) has been changed.

Also, to increase the pressure resisting strength, flare processing dimensions and sizes of opposite sides of flare

nuts (for copper pipes with nominal diameters 1/2 and 5/8) have been changed. During installation/service,

therefore, prepare tools exclusive for R410A shown in (1) below and general tools shown in (2) on page 48.

chargedaccidentally, the service port diameter of the outdoor unit control valve (3-way valve) has been changed.

Also, to increase the pressure resisting strength, flare processing dimensions and sizes of opposite sides of flare

nuts (for copper pipes with nominal diameters 1/2 and 5/8) have been changed. During installation/service,

therefore, prepare tools exclusive for R410A shown in (1) below and general tools shown in (2) on page 48.

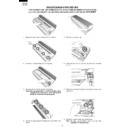

(1) Tools Exclusive for R410A

a) Gauge Manifold

As R410A is characterized by high pressure, conventional tools cannot be used.

Table 9. Differences between Conventional High/Low Pressure Gauges and Those for R410A

High pressure

gauge (red)

gauge (red)

Conventional gauges

Gauges exclusive for R410A

- 0.1 ~ 3.5 MPa

- 76 cmHg ~ 35 kgf/cm

2

- 0.1 ~ 1.7 MPa

- 76 cmHg ~ 17 kgf/cm

2

- 0.1 ~ 5.3 MPa

- 76 cmHg ~ 53 kgf/cm

2

- 0.1 ~ 3.8 MPa

- 76 cmHg ~ 38 kgf/cm

2

Compound

gauge (blue)

gauge (blue)

In order to prevent any other refrigerant from being charged accidentally, each port of yhe manifold has

been changed in shape.

been changed in shape.