Panasonic KX-DT543RU / KX-DT546RU Service Manual ▷ View online

41

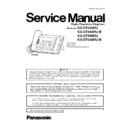

KX-DT543RU/KX-DT543RU-B/KX-DT546RU/KX-DT546RU-B

10 Miscellaneous

10.1. Terminal Guide of the ICs Transistors and Diodes

10.1.1.

Main Board

10.1.2.

Operation Board

42

KX-DT543RU/KX-DT543RU-B/KX-DT546RU/KX-DT546RU-B

10.2. How To Replace a Flat Package IC

Even if you do not have the special tools (for example, a spot heater) to remove the Flat IC, with some solder (large amount), a sol-

dering iron and a cutter knife, you can easily remove the ICs that have more than 100 pins.

dering iron and a cutter knife, you can easily remove the ICs that have more than 100 pins.

10.2.1.

Preparation

• PbF (: Pb free) Solder

• Soldering Iron

• Soldering Iron

Tip Temperature of 700

F ± 20F (370C ± 10C)

Note: We recommend a 30 to 40 Watt soldering iron. An

expert may be able to use a 60 to 80 Watt iron where some-

one with less experience could overheat and damage the

PCB foil.

expert may be able to use a 60 to 80 Watt iron where some-

one with less experience could overheat and damage the

PCB foil.

• Flux

Recommended Flux: Specific Gravity

0.82.

Type

RMA (lower residue, non-cleaning type)

Note: See About Lead Free Solder (PbF: Pb free) (P.4).

10.2.2.

Removal Procedure

1. Put plenty of solder on the IC pins so that the pins can be

completely covered.

Note:

Note:

If the IC pins are not soldered enough, you may give

pressure to the P.C. board when cutting the pins with

a cutter.

pressure to the P.C. board when cutting the pins with

a cutter.

2. Make a few cuts into the joint (between the IC and its

pins) first and then cut off the pins thoroughly.

3. While the solder melts, remove it together with the IC

pins.

When you attach a new IC to the board, remove all solder

left on the land with some tools like a soldering wire. If some

solder is left at the joint on the board, the new IC will not be

attached properly.

left on the land with some tools like a soldering wire. If some

solder is left at the joint on the board, the new IC will not be

attached properly.

10.2.3.

Procedure

1. Tack the flat pack IC to the PCB by temporarily soldering

two diagonally opposite pins in the correct positions on

the PCB.

the PCB.

Be certain each pin is located over the correct pad on the PCB.

2. Apply flux to all of the pins on the IC.

3. Being careful to not unsolder the tack points, slide the sol-

dering iron along the tips of the pins while feeding enough

solder to the tip so that it flows under the pins as they are

heated.

solder to the tip so that it flows under the pins as they are

heated.

10.2.4.

Removing Solder From Between

Pins

Pins

1. Add a small amount of solder to the bridged pins.

2. With a hot iron, use a sweeping motion along the flat part

2. With a hot iron, use a sweeping motion along the flat part

of the pin to draw the solder from between the adjacent

pads.

pads.

43

KX-DT543RU/KX-DT543RU-B/KX-DT546RU/KX-DT546RU-B

10.2.5.

Memo

44

KX-DT543RU/KX-DT543RU-B/KX-DT546RU/KX-DT546RU-B

11 Schematic Diagram

11.1. Main No.1

DG

DG

DG

SPI2_DO

PCM_RXD

PCM_TXD

PCM_FSYNC

SPI2_DI

PCM_SCLK

SPI2_CS

SPI2_CLK

RESET

CK4M

VCC33

PEP1

PSYNC

DG

INTN

DG

R324

820

R323

1M

GPIO3

GPIO4

C323 0.1u

C324

0.1u

C326 0.1u

C327 1000p

C328

1000p

C329

1000p

C362

0.01u

16

X301

16.384M

C566

NC

AGND

DG

R561

NC

PG

DG

R562

NC

R330

1k

C563

0

C564

0

C565

0

C567

0

R332

1k

R331

1k

R333

270

C572

0

C573

0

C383

7p

C382

7p

R334

R571

NC

R572

NC

R573

0

AGND

DG

IC300

13 CK4M

14 VSS2

15 GPIO0

16 VSS3

17 GPIO1

18 GPIO2

19 VDD1

20 GPIO3

21 DVRL

22 DDR

23 DVRH

24 NC1

25

GPIO4

26

PVRL

27

PDR

28

PVRH

29

NC2

30

VDD2

31

VSS4

32

PDX1

33

PDX0

34

GPIO5

35

GPIO6

36

GPIO7

37

VSS5

38

OSI

39

OSO

40

VSS6

41

INTN

42

VSS7

43

VDD3

44

NC3

45

STEST0

46

STEST1

47

DDX0

48

DDX1

1

RSTN

2

OSR

3

OEP0

4

OEP1

5

OSYNC

6

VSS1

7

OCLK

8

OSX

9

SPITX

10

SPIRX

11

SPICLK

12

SPICS

(1)

(2)

(3)

(4)

(2)

(3)

(4)

(5)

(6)

(7)

(7)

(8)

(9)

(10)

(10)

(11)

(12)

KX-DT543

58/KX-DT54658 MAIN BOARD NO.1 (1/2)

(4) Clock (IC300:ASIC1) 16.384MHz

(8) IC300(ASIC1) - IC410(DCX81) signal (Reset)

(9) IC300(ASIC1) -IC410(DCX81) signal (SPI2)

(10) IC300(ASIC1) - IC410(DCX81) signal (PCM)

(11) DPT - PBX signal (Receiving signals)

(16) DXDP signal (Receiving signals)

Click on the first or last page to see other KX-DT543RU / KX-DT546RU service manuals if exist.