Panasonic WV-CP250 / WV-CP254E Service Manual ▷ View online

ORDER NO. AVS0402525C8

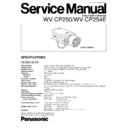

Colour CCTV Cameras

WV-CP250/WV-CP254E

WV

-

CP250

SPECIFICATIONS

Pick-up device:

752 (H) x 582 (V) pixels, interline transfer CCD

Scanning area:

5.59 (H) x 4.68 (V) mm (equivalent to scanning area of 1/3” pick-up tube)

Synchronization:

internal, line-locked or multiplexed vertical drive (VD2), selectable

Scanning system:

2 : 1 interlace

Scanning:

625 lines / 50 fields / 25 frames

Horizontal:

15.625 kHz

Vertical:

50 Hz

Horizontal resolution:

480 lines

Video output:

1.0 V[p-p] PAL composite 75

Ω

/ BNC connector

Signal-to-noise ratio:

50 dB (min) (at AGC Off, weight On)

Electronic light control:

equivalent to continuous variable shutter speed between 1/50 s and 1/15 000 s

Minimum illumination:

1.0 lx (0.1 foot-candle) at colour mode, 0.15 lx (0.015 foot-candle) at black and white mode with

F1.4 lens

F1.4 lens

Aperture:

SHARP or SOFT, selectable

Lens mount:

CS-mount

Ambient operating temperature: -10 °C - +50 °C (14 °F - 122 °F)

Ambient operating humidity:

Ambient operating humidity:

less than 90 %

Power source and

WV-CP250:

220 V - 240 V AC 50 Hz, 3.9 W

power consumption:

WV-CP254E:

12 V DC 300 mA

24 V AC 50 Hz, 3.3 W

24 V AC 50 Hz, 3.3 W

Dimensions (without lens):

70 mm (W) x 55 mm (H) x 118 mm (D)

2-3/4" (W) x 2-3/16" (H) x 4-5/8" (D)

2-3/4" (W) x 2-3/16" (H) x 4-5/8" (D)

Weights (without lens):

WV-CP250:

0.460 kg (1.01 lbs)

WV-CP254E:

0.450 kg (0.99 lbs)

Day/Night

selectable COLOUR FIX (

→

external terminal active) or AUTO

Weights and dimensions indicated are approximate.

Specifications are subject to change without notice.

Specifications are subject to change without notice.

2 0 0 3

M a t s u s h i t a E l e c t r i c I n d u s t r i a l C o . , L t d .

A l l r i g h t s r e s e r v e d . U n a u t h o r i z e d c o p y i n g a n d

d i s t r i b u t i o n i s a v i o l a t i o n o f l a w .

d i s t r i b u t i o n i s a v i o l a t i o n o f l a w .

The Product with PbF

(Lens: Option)

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION:

TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK). NO USER

SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK). NO USER

SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

This symbol warns the user that uninsulated voltage within

the unit may have sufficient magnitude to cause electric

shock. Therefore, it is dangerous to make any kind of contact

with any inside part of this unit.

the unit may have sufficient magnitude to cause electric

shock. Therefore, it is dangerous to make any kind of contact

with any inside part of this unit.

This symbol alerts the user that important literature concerning

the operation and maintenance of this has been included.

Therefore, it should be read carefully in order to avoid

any problems.

the operation and maintenance of this has been included.

Therefore, it should be read carefully in order to avoid

any problems.

T

here are special components used in this equipment which are important for safety. These parts are indicated

by the ”

Y

” mark on the schematic diagram and the replacement parts list. It is essential that these critical

parts should be replaced with manufacturer's specified parts to prevent X-radiation, shock, fire, or other hazards.

Do not modify the original design without permission of manufacture.

IMPORTANT SAFETY NOTICE

About Lead Free Solder (PbF)

Distribution of PbF PCB:

PCBs (manufactured) using lead free solder (PbF) will have a stamp on the PCB.

Caution:

8

Lead free solder has a higher melting point than standard solder. Typically the melting points is 35

°

C – 40

°

C

(95

°

F – 104

°

F) higher. Please use a soldering iron with temperature control and adjust it to 360

°

C – 370

°

C

(680

°

F – 698

°

F). In case of using high temperature soldering iron, please be careful not to heat too long.

8

Lead free solder will tend to splash when heated too high (600

°

C / 1112

°

F).

8

Lead free solder (Sn - 3.0Ag – 0.5Cu) or equivalents are recommended on repairing our lead free soldered PCB.

Y

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the

general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to

service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any

attempt to service or repair the product or products dealt with in this service information by anyone else could

result in serious injury or death.

general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to

service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any

attempt to service or repair the product or products dealt with in this service information by anyone else could

result in serious injury or death.

STANDARD ACCESSORIES

Operating Instructions ............................................................ 1 pc.

The following parts are for installation:

Body cap ................................................................................ 1 pc.

ALC lens connector (YWM1943A) ......................................... 1 pc.

AC Power Cord (only for WV-CP250) .................................... 1 pc.

The following parts are for installation:

Body cap ................................................................................ 1 pc.

ALC lens connector (YWM1943A) ......................................... 1 pc.

AC Power Cord (only for WV-CP250) .................................... 1 pc.

CONTENTS

MAJOR OPERATING CONTROLS AND THEIR FUNCTIONS ......................................................... 1-1

ADJUSTMENT PROCEDURE ............................................................................................................ 2-1

WIRING DIAGRAM ............................................................................................................................. 3-1

SCHEMATIC DIAGRAM

SENSOR BOARD

PARTITION DIAGRAM ...........................................................................................................4-1-1

(1/4).........................................................................................................................................4-1-2

(2/4).........................................................................................................................................4-1-3

(3/4).........................................................................................................................................4-1-4

(4/4).........................................................................................................................................4-1-5

MAIN BOARD

PARTITION DIAGRAM ..........................................................................................................4-2-1

(1/4).........................................................................................................................................4-2-2

(2/4).........................................................................................................................................4-2-3

(3/4).........................................................................................................................................4-2-4

(4/4).........................................................................................................................................4-2-5

I/F BOARD .....................................................................................................................................4-3

POWER BOARD

(WV-CP250) ..............................................................................................................................4-4

(WV-CP254E).............................................................................................................................4-5

CONDUCTOR VIEW

SENSOR BOARD ...........................................................................................................................5-1

MAIN BOARD .................................................................................................................................5-2

I/F BOARD ......................................................................................................................................5-3

POWER BOARD

(WV-CP250) ..............................................................................................................................5-4

(WV-CP254E).............................................................................................................................5-5

EXPLODED VIEW

(WV-CP250) .....................................................................................................................................6-1

(WV-CP254E)...................................................................................................................................6-2

REPLACEMENT PARTS LIST ...........................................................................................................7-1

1-1

MAJOR OPERATING CONTROLS AND THEIR FUNCTIONS

WV-

CP250

CP250

<WV-CP250>

<WV-CP254>

Fixing screws

Camera mounting

screw holes

screw holes

Mount adapter

WV-

CP250

WV-

CP25

BLC

ONAGC

HI

SHARP

COCOUR

FIX

VIDEO

HI

1MIN

ATW1

ALC

INT

5SEC

ATW2

ELC

LL LOW

AUTO

DC

OFF

DAY/NIGHT

SOFT

LOW

DAY/

NIGHT

GND

GND

IN

VIDEO OUT

POWER

1-L

2-L

AC 24V IN

DC 12V IN

DAY/

NIGHT

GND

IN

VIDEO OUT

POWER

220-240V E 50Hz

0

!5

!5

!6

!7

!6

!7

!9

!8

e

r

q

w

o

u

t

!1

!3

!0

i

y

!2

!4

q

Auto Iris Lens Connector

Supplies power and control signals to an auto iris lens (not

supplied).

supplied).

w

Focus Lock Knob

This knob adjusts the back-focal distance or picture focus.

e

Lens (option)

r

Mount Adapter

The camera mounting screw hole is for mounting the camera

onto a mounting bracket. The camera is originally designed to

be mounted from the bottom, however, a top-mounting type is

also available. To mount from the top, remove the mount

adapter from the bottom of the camera by removing two fixing

screws. Attach the mount adapter to the top as shown in the

diagram, then mount the camera on the mounting bracket.

Make sure that two original screws are used when mounting

the mount adapter; longer type screws may damage inner

components, too shorter type screws may cause the camera

drop.

onto a mounting bracket. The camera is originally designed to

be mounted from the bottom, however, a top-mounting type is

also available. To mount from the top, remove the mount

adapter from the bottom of the camera by removing two fixing

screws. Attach the mount adapter to the top as shown in the

diagram, then mount the camera on the mounting bracket.

Make sure that two original screws are used when mounting

the mount adapter; longer type screws may damage inner

components, too shorter type screws may cause the camera

drop.

t

Synchronization Mode Selector (INT, LL)

Selects the camera synchronization mode as either internal

sync mode (INT) or line-lock mode (LL).

sync mode (INT) or line-lock mode (LL).

INT:

Sets to internal 2:1 interlace.

LL:

Sets to Line-lock mode.

Note:

Do not set the switch to the LL position when sup-

plying 12 V DC to avoid a synchronization error.

y

Back Light Compensation Mode Selector (BLC ON, OFF)

Lets you select the mode according to the position of the

object and light conditions on the screen.

object and light conditions on the screen.

ON:

Select this mode when a strong light such as a spotlight

is in the background.

OFF:

Normal picture

The factory default setting is OFF.

u

AGC Level Selector

AGC level can be selected with this selector. AGC automati-

cally controls the gain of Image brightness level.

cally controls the gain of Image brightness level.

HI:

This setting raises more the gain and brightness of images

under low light conditions.

LOW:

Normal position

i

Detail/Aperture Level Selector (SHARP, SOFT)

The detail/aperture level can be selected with this selector.

Set it to the desired position while observing the picture on the

monitor.

Set it to the desired position while observing the picture on the

monitor.

SHARP:

Normal position.

SOFT:

Select this position when a Quad System is connected

to this camera.

o

Automatic Light Control/Electronic Light Control Selector

(ALC, ELC)

(ALC, ELC)

Lets you select the mode according to the lens type used.

ALC:

Select this mode when an auto iris lens (ALC lens) is

used with this camera.

ELC:

Select this mode when a fixed iris lens or manual iris

lens is used with this camera.

!0

Lens Drive Signal Selector (VIDEO, DC)

Lets you select the mode according to the type of auto iris

lens drive signal to be supplied to the lens from the auto iris

lens connector.

lens drive signal to be supplied to the lens from the auto iris

lens connector.

VIDEO:

Select this mode if you are using a auto iris lens that

requires a video drive signal.

DC:

Select this mode if you are using a auto iris lens that

requires a DC drive signal.

!1

Auto-Tracing White Balance mode (ATW) Selector

The ATW mode can be selected with this selector.

ATW1:

Normal picture

ATW2:

ATW in sodium lamp mode