Panasonic SA-MAX370GS / SA-MAX770GS Simplified Service Manual ▷ View online

5

1.4.

Caution For AC Cord

6

1.5.

Caution For Fuse Replacement

1.6.

Safety Parts Information

Safety Parts List:

There are special components used in this equipment which are important for safety.

These parts are marked by

in the Schematic Diagrams, Exploded View & Replacement Parts List. It is essential that these

critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the

original design without permission of manufacturer.

original design without permission of manufacturer.

Safety

Ref No.

Part No.

Part Name & Description

Remarks

25

RGR0455C-A1

REAR PANEL

MAX770

25

RGR0455F-A

REAR PANEL

MAX370

40

RKM0744-K2

TOP CABINET

301

RAE1045Z-V

TRAVERSE ASS'Y

A2

K2CJ2YY00097

AC CORD

A2

K2CP2YY00071

AC CORD

A2

K2CQ2YY00127

AC CORD

A2

K2CT2YY00103

AC CORD

A3

VQT5F33

O/I BOOK (En/CN/Ru/Ur/Ar)

MAX770

A3

VQT5F34

O/I BOOK (En/CN/Ru/Ur/Ar)

MAX370

PCB13

REP5035B

SMPS P.C.B.

(RTL)

DZ1001

D4EAY511A127

VARISTOR

(E.S.D)

L1001

G0B183J00002

LINE FILTER

L1002

G0B183J00002

LINE FILTER

T1101

G0C400K00001

TRANSFORMER

T1203

G0C400K00001

TRANSFORMER

T1401

G4DYZ0000076

TRANSFORMER

T1501

G4DYA0000520

TRANSFORMER

T1502

G4DYA0000520

TRANSFORMER

Q1403

B3PBA0000579

PHOTO COUPLER

Q1404

B3PBA0000579

PHOTO COUPLER

Q1405

B3PBA0000579

PHOTO COUPLER

Q1505

B3PBA0000579

PHOTO COUPLER

F1001

K5D103BNA005

FUSE

F1401

K5G501YA0081

FUSE PROTECTOR

F1501

K5G502Y00006

FUSE PROTECTOR

P1001

K2AZYA000005

AC INLET

R1001

D0GF105JA048

1M 1/4W

R1002

D0GF105JA048

1M 1/4W

C1001

F0CAF224A105

0.22uF

C1002

F0CAF224A105

0.22uF

C1003

F1BAF221A013

220pF

C1004

F1BAF221A013

220pF

C1006

F0CAF104A105

0.1uF

C1518

F1BAF471A013

470pF

7

2 Warning

2.1.

Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensi-

tive (ES) Devices

tive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Elec-

trostatically Sensitive (ES) Devices.

trostatically Sensitive (ES) Devices.

The following techniques should be used to help reduce the incidence of component damage caused by electrostatic discharge

(ESD).

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alumi-

num foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or compara-

ble conductive material).

ble conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION:

CAUTION:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) suf-

ficient to damage an ES device).

ficient to damage an ES device).

2.2.

Precaution of Laser Diode

Caution:

This product utilizes a laser diode with the unit turned “on”, invisible laser radiation is emitted from the pickup lens.

Wavelength: 790 nm (CD)

Maximum output radiation power from pickup: 100

Wavelength: 790 nm (CD)

Maximum output radiation power from pickup: 100

μ

W/VDE

Laser radiation from the pickup unit is safety level, but be sure the followings:

1. Do not disassemble the pickup unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pickup unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pickup lens for a long time.

2. Do not adjust the variable resistor on the pickup unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pickup lens for a long time.

8

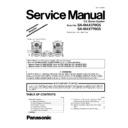

Figure 2-1

2.3.

General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86

°

F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30 degrees

C (662±86

°

F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn), 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

2.4.

Handling Precautions for Traverse Ass’y

The laser diode in the optical pickup unit may break down due to static electricity of clothes or human body. Special care must be

taken avoid caution to electrostatic breakdown when servicing and handling the laser diode in the traverse unit.

taken avoid caution to electrostatic breakdown when servicing and handling the laser diode in the traverse unit.

2.4.1.

Cautions to Be Taken in Handling the Optical Pickup Unit (OPU)

The laser diode in the optical pickup unit may be damaged due to electrostatic discharge generating from clothes or human body.

Special care must be taken avoid caution to electrostatic discharge damage when servicing the laser diode.

Special care must be taken avoid caution to electrostatic discharge damage when servicing the laser diode.

1. Do not give a considerable shock to the optical pickup unit as it has an extremely high-precise structure.

2. To prevent the laser diode from the electrostatic discharge damage, the flexible cable of the optical pickup unit removed

2. To prevent the laser diode from the electrostatic discharge damage, the flexible cable of the optical pickup unit removed

should be short-circuited with a short pin or a clip.

3. The flexible cable may be cut off if an excessive force is applied to it. Use caution when handling the flexible cable.

4. The antistatic FFC is connected to the new optical pickup unit. After replacing the optical pickup unit and connecting the flexi-

4. The antistatic FFC is connected to the new optical pickup unit. After replacing the optical pickup unit and connecting the flexi-

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

(See right figure)

Click on the first or last page to see other SA-MAX370GS / SA-MAX770GS service manuals if exist.