Panasonic WH-SDC07F3E5 / WH-SDC09F3E5 / WH-UD07FE5 / WH-UD09FE5 Service Manual ▷ View online

37

11.3.3.6

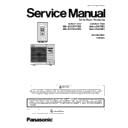

Drain Elbow and Hose Installation

Fix the drain elbow and packing to the bottom

of indoor unit, as shown in below illustration.

Use inner diameter 17 mm drain hose in the

market.

This hose must to be installed in a continuously

downward direction and in a frost-free

environment.

environment.

Guides this hose’s outlet to outdoor only.

Do not insert this hose into sewage or drain pipe

that may generate ammonia gas, sulfuric gas, etc.

If necessary, use hose clamp to further tighten the

hose at drain hose connector to prevent leakage.

Water will drip from this hose, therefore the outlet

of this hose must be installed in an area where the

outlet cannot become blocked.

outlet cannot become blocked.

Water Connector

Packing 9

Drain Elbow 10

11.3.4 Connect the Cable to the Indoor Unit

1 Connecting cable between indoor unit and outdoor unit shall be approved polychloroprene sheathed 4 × min

4.0 or 6.0 mm

2

flexible cord, type designation 60245 IEC 57 or heavier cord.

o

Ensure the colour of wires of outdoor unit and the terminal no. are the same to the indoor unit’s

respectively.

respectively.

o

Earth wire shall be longer than the other wires as shown in the figure for the electrical safety in case of

the slipping out of the cord from the Holder (Clamper).

the slipping out of the cord from the Holder (Clamper).

2 An isolating device must be connected to the power supply cable.

o

Isolating device (Disconnecting means) should have minimum 3.0 mm contact gap.

o

Connect the approved polychloroprene sheathed power supply 1 cord (3 × min 4.0 or 6.0 mm

2

) and

power supply 2 cord (3 × min 4.0 mm

2

), type designation 60245 IEC 57 or heavier cord to the terminal

board, and to the other end of the cord to isolating device (Disconnecting means).

3 To avoid the cable and cord being damaged by sharp edges, the cable and cord must be passed through a

bushing (located at the bottom of indoor unit) before being connected to the terminal block. The bushing must

be used and must not be removed.

be used and must not be removed.

Indoor unit/

Outdoor unit connection

1

2

3

2

3

1

L

N

N

L

Power Supply 1

Terminal on the outdoor unit

Colour of wires (Connecting cables)

Terminal on the indoor unit

(Power Supply Cord)

Terminals on the isolating device from

Colour of wires (Connecting cables)

Terminal on the indoor unit

(Power Supply Cord)

Terminals on the isolating device from

power supply (Disconnecting means)

L

1

N

1

L

1

N

1

Power Supply 2

Connecting with external device (optional)

1 All connections shall follow to the local national wiring standard.

2 It is strongly recommended to use manufacturer-recommended parts and accessories for installation.

3 Maximum output power of booster heater should be ≤ 3 kW. Booster Heater cord must be (3 × min 1.5 mm

2 It is strongly recommended to use manufacturer-recommended parts and accessories for installation.

3 Maximum output power of booster heater should be ≤ 3 kW. Booster Heater cord must be (3 × min 1.5 mm

2

),

of type designation 60245 IEC 57 or heavier.

4 Two-way Valve shall be spring and electronic type, refer to “Field Supply Accessories” table for details. Valve

cable shall be (3 × min 0.5 mm

2

), of type designation 60245 IEC 57 or heavier, or similarly double insulation

sheathed cable.

* note: - Two-way Valve shall be CE marking compliance component.

- Maximum load for the valve is 9.8 VA.

* note: - Two-way Valve shall be CE marking compliance component.

- Maximum load for the valve is 9.8 VA.

5 Three-Way Valve shall be spring and electronic type. Valve's cable shall be (3 × min 0.5 mm

2

), of type

designation 60245 IEC 57 or heavier, or similarly double insulation sheathed cable.

* note: - Shall be CE marking compliance component.

- It shall be directed to heating mode when it is OFF.

- Maximum load for the valve is 9.8 VA.

* note: - Shall be CE marking compliance component.

- It shall be directed to heating mode when it is OFF.

- Maximum load for the valve is 9.8 VA.

6 Room Thermostat cable must be (4 or 3 × min 0.5 mm

2

), double insulation layer of PVC-sheathed or rubber-

sheathed cable.

7 Tank OLP cable must be (2 × min 0.5 mm

2

), double insulation layer of PVC-sheathed or rubber-sheathed

cable.

* note: - if such connection deemed NO necessary for tank OLP, please connect jumper between terminal

* note: - if such connection deemed NO necessary for tank OLP, please connect jumper between terminal

no. 13 and 14.

8 Tank Sensor shall be resistance type, please refer to Graph 5.1 for the characteristic and details of sensor.

Its cable shall be (2 × min 0.3 mm

2

), double insulation layer (with insulation strength of min 30 V) of PVC-

sheathed or rubber-sheathed cable.

38

9 External Controller shall be connected to 1-pole switch with min 3.0 mm contact gap. (connection refer to

Diagram 5.2). Its cable must be (2 × min 0.5 mm

2

), double insulation layer of PVC-sheathed or rubber-

sheathed cable.

* note: - When making such connection, kindly remove the jumper between terminal no. 17 and 18.

- Switch used shall be CE compliance component.

- Maximum operating current shall be less than 3A

* note: - When making such connection, kindly remove the jumper between terminal no. 17 and 18.

- Switch used shall be CE compliance component.

- Maximum operating current shall be less than 3A

rms

.

10 Must install Solar Connection PCB (optional) to indoor unit when Solar Pump Station is utilized. Refer

Solar Connection PCB’s installation instruction for detail of installation.

11 Solar Three-way Valve cable shall be (3 × min 0.5 mm

2

), double insulation layer PVC-sheathed or rubber-

sheathed cable.

12 Solar Pump Station cable shall be (2 × min 0.5 mm

2

), of double insulation PVC-sheathed or rubber-sheathed

cable. Strongly recommended install with maximum length of 10 meter only.

Tank

OLP

Cable

Terminals on the indoor

Lead wire cord

1

2

3

4

5

6

Three-way

Valve Cable

Two-way

Valve Cable

Solar Pump

Station Cable

External

Controller

Cable

7

8

9 10 11 12

13 14 15 16 17 18

19 20 21

23

22

24

Booster Heater

Cord

Room Thermostat

Cable

Solar Three-way

Valve Cable

Only if Solar Connection PCB installed

Tank

Sensor

Cable

H

EAT

CO

O

O

L

N

N

L

L

N

N

O

PEN

O

PEN

CL

O

O

S

E

CL

O

O

S

E

N

CL

O

O

S

E

O

PEN

A

LN11

N

L 11

How to guide the lead wires and power supply cord

(view without internal wiring)

Bind all optional

cables and cords

with this band

Earth wire must be longer than other

cables for safety reasons.

Bind all optional cables and cords with this band

Holder (Clamper)

Holder (Clamper)

Power Supply 1

RCCB/ELCB

Power Supply 2

RCCB/ELCB

Earth wire must

be longer than

other cables for

safety reasons.

Indoor unit bottom

Holder (Clamper)

Power

Supply 2

Power

Supply 1

Connecting

cables

Bushing

Indoor terminal for

connecting cables

39

Solar Three-way Valve

Cable (Optional)

External Control Cable

External Control Cable

(Optional)

Tank Sensor Cable

Tank Sensor Cable

(Optional)

Tank OLP Cable (Optional)

Tank OLP Cable (Optional)

Detail A

Solar Pump Station Cable

(Optional)

Three-way Valve Cable

(Optional)

Two-way Valve Cable

Two-way Valve Cable

(Optional)

Earth wire must be longer

than other cables for safety

reasons.

Room Thermostat Cable

(Optional)

Booster Heater Cord

Booster Heater Cord

(Optional)

11.3.4.1

Wire Stripping and Connecting Requirement

-30

-10

0

10

20

30

-20

16000

14000

12000

10000

14000

12000

10000

8000

˚C

6000

4000

2000

4000

2000

0

Graph 5.1: Tank sensor characteristic

Tank Sensor Resistance Vs Temperature

R

e

si

sta

n

ce

(

Ω)

Wire stripping

5mm or

more

(gap between

wires)

No loose strand

when insert

Indoor/outdoor

connecting

terminal board

1

0

±

1

m

m

ACCEPT

PROHIBITED

Conductor

over insert

over insert

Conductor not

fully insert

Conductor

fully insert

PROHIBITED

17

18

18

Diagram 5.2: External Controller connecting

diagram

External Controller

Terminal

Switch (ON/OFF)

Remove this

jumper if External

Controller

(Optional) is

connected to the

indoor unit

jumper if External

Controller

(Optional) is

connected to the

indoor unit

11.3.4.2 Connecting

Requirement

The equipment’s power supply 1 complies with IEC/EN 61000-3-12 provided that the short-circuit power S

sc

is

greater than or equal to 850 kW (for WH-SDC07/09F3E5/UD07/09FE5) at the interface point between the user’s

supply and the public system. It is the responsibility of the installer or user of the equipment to ensure, by

consultation with the distribution network operator if necessary, that the equipment is connected only to a supply

with a short-circuit power S

supply and the public system. It is the responsibility of the installer or user of the equipment to ensure, by

consultation with the distribution network operator if necessary, that the equipment is connected only to a supply

with a short-circuit power S

sc

greater than or equal to 850 kW.

The equipment's power supply 1 shall be connected to a suitable supply network, having service current capacity

≥ 100A per phase. Please liaise with supply authority to ensure that the service current capacity at the interface

point is sufficient for the installation of the equipment.

point is sufficient for the installation of the equipment.

The equipment’s power supply 2 complies with IEC/EN 61000-3-12.

The equipment’s power supply 2 shall be connected to a suitable supply network, having service current capacity

≥ 100A per phase. Please liaise with supply authority to ensure that the service current capacity at the interface

point is sufficient for the installation of the equipment.

point is sufficient for the installation of the equipment.

40

11.4 Outdoor

Unit

11.4.1 Install the Outdoor Unit

After selecting the best location, start installation

according to Indoor/Outdoor Unit Installation

Diagram.

1 Fix the unit on concrete or rigid frame firmly

Diagram.

1 Fix the unit on concrete or rigid frame firmly

and horizontally by bolt nut (ø10 mm).

2 When installing at roof, please consider strong

wind and earthquake. Please fasten the

installation stand firmly with bolt or nails.

(Unit in mm)

installation stand firmly with bolt or nails.

(Unit in mm)

140

355

44

620

140

20

2

5

450

(A

nc

hor

p

itc

h

)

(Anchor pitch)

11.4.2 CONNECTING THE PIPING

Model

Piping size (Torque)

Gas

Liquid

WH-SDC07/09F3E5

WH-UD07/09FE5

ø15.88 mm

(5/8")

[65 N•m]

Ø6.35 mm

(1/4")

[18 N•m]

Connecting The Piping To Outdoor Unit

Decide piping length and then cut by using pipe cutter.

Remove burrs from cut edge. Make flare after

inserting the flare nut (locate at valve) onto the copper

pipe.

Align center of piping to valves and then tighten with

torque wrench to the specified torque as stated in the

table.

Local pipes can project in any of four directions.

Make holes in the pipe panels for the pipes to

pass through.

Be sure to install the pipe panels to prevent rain

from getting inside the outdoor unit.

[Removing the service panel].

1 Remove the three mounting screws.

2 Slide the service panel downward to release

[Removing the service panel].

1 Remove the three mounting screws.

2 Slide the service panel downward to release

the pawls.

After this, pull the service panel toward you to remove

it.

it.

CAUTION

Do not over tighten, over tightening cause gas leakage.

Front pipe panel

Rear pipe

panel

Mounting

screws

Service panel

Forward

direction

Downward

direction

Side panel

Rear direction

Close the tube joining area

with putty heat insulator

(local supply) without any

gap as shown in right figure.

(To prevent insects or small

animal entering.)

Be sure to use two spanners

to tighten.

(If the nuts are over

tightened, it may cause

the flares to break

or leak.)

Do not attach

the spanners

here

the spanners

here

Putty or Heat

insulator

(local supply)

Click on the first or last page to see other WH-SDC07F3E5 / WH-SDC09F3E5 / WH-UD07FE5 / WH-UD09FE5 service manuals if exist.