Panasonic WH-SDC07F3E5 / WH-SDC09F3E5 / WH-UD07FE5 / WH-UD09FE5 Service Manual ▷ View online

33

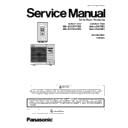

10.2.2 Noise Filter Printed Circuit Board

FG1

FG2

CN-WHT

CN-ACL

CN-ACN

CN-BLK

AC-BLK

10.2.3 Capacitor Printed Circuit Board

AC-C

DCN-IN

DCP-IN

DCN-OUT

34

11. Installation Instruction

11.1 Select the Best Location

INDOOR UNIT

There should not be any heat source or steam

near the unit.

A place where air circulation in the room is good.

A place where drainage can be easily done.

A place where noise prevention is taken into

consideration.

Do not install the unit near the door way.

Ensure the spaces indicated by arrows from the

wall, ceiling, fence or other obstacles.

Recommended installation height for indoor unit

shall be at least 800 mm.

Must install on a vertical wall.

When install electrical equipment at wooden

building of metal lath or wire lath, according to

electrical facility technical standard, no electrical

contact between equipment and building is

allowed. Insulator must be installed in between.

electrical facility technical standard, no electrical

contact between equipment and building is

allowed. Insulator must be installed in between.

Do not install the unit at outdoor. This is designed

for indoor installation only.

When connecting solar pump station cable

between indoor unit and solar pump station, the

distance between both apparatuses shall be 2 ~ 8

meters and the maximum length of 10 meter only.

Failure to do so may lead to abnormal operation

to the system.

distance between both apparatuses shall be 2 ~ 8

meters and the maximum length of 10 meter only.

Failure to do so may lead to abnormal operation

to the system.

OUTDOOR UNIT

If an awning is built over the unit to prevent direct

sunlight or rain, be careful that heat radiation from

the condenser is not obstructed.

the condenser is not obstructed.

Avoid installations in areas where the ambient

temperature may drop below -20°C.

Keep the spaces indicated by arrows from wall,

ceiling, fence or other obstacles.

Do not place any obstacles which may cause a

short circuit of the discharged air.

If outdoor unit installed near sea, region with high

content of sulphur or oily location (e.g. machinery

oil, etc), it lifespan maybe shorten.

oil, etc), it lifespan maybe shorten.

When installing the product in a place where it will

be affected by typhoon or strong wind such as

wind blowing between buildings, including the

rooftop of a building and a place where there is no

building in surroundings, fix the product with an

overturn prevention wire, etc. (Overturn prevention

fitting model number: K-KYZP15C)

wind blowing between buildings, including the

rooftop of a building and a place where there is no

building in surroundings, fix the product with an

overturn prevention wire, etc. (Overturn prevention

fitting model number: K-KYZP15C)

If piping length is over 10 m, additional refrigerant

should be added as shown in the table.

Model

Piping size

Standard

Length

(m)

Max.

Elevation

(m)

Min.

Piping

Length

(m)

Max.

Piping

Length

(m)

Additional

Refrigerant

(g/m)

Gas

Liquid

WH-SDC07/09F3E5

WH-UD07/09FE5

ø15.88mm

(5/8")

ø6.35mm

(1/4")

5~7.5

20

3

30

30

Example :

If piping length is 30 m, the quantity of additional

refrigerant should be 600 g. [(30-10)m × 30 g/m = 600

g]

11.2 Indoor/Outdoor

Unit

Installation Diagram

Check that all the

cables do not touch

the hot piping, etc.

cables do not touch

the hot piping, etc.

Check that the cables do not

touch the compressor, etc.

touch the compressor, etc.

Vinyl tape

(Wide)

Saddle

Indoor/Outdoor connecting cable (4-CORE WIRE min 4.0 or 6.0 mm²)

Type designation 60245 IEC 57 or heavier cord

ø15.88 mm (5/8")

Gas refrigerant piping

ø6.35 mm (1/4")

Liquid refrigerant piping

100mm

or more

1000

mm

or mo

re

100

mm

or m

ore

300mm

or more

300 mm

or more

300 mm or more

300 mm

or more

Drain Hose

ø15.88 mm (5/8") Gas

Refrigerant Piping

ø6.35 mm (1/4") Liquid

Refrigerant Piping

Water Outlet piping

Water Inlet piping

Type

designation

60245 IEC

57 or heavier

cord/ cable

designation

60245 IEC

57 or heavier

cord/ cable

•

Indoor unit/Outdoor unit connecting cable

(4

(4

×

min 4.0 or 6.0 mm²)

•

Power Supply 1 cord (3

×

min 4.0 or 6.0 mm²)

•

Power Supply 2 cord (3

×

min 4.0 mm²)

•

2-way Valve cable

(3

(3

×

min 0.5 mm²)

•

3-way Valve cable

(3

(3

×

min 0.5 mm²)

•

Booster Heater cord

(3

(3

×

min 1.5 mm²)

•

Room Thermostat cable

(4 or 3

(4 or 3

×

min 0.5 mm²)

•

Tank OLP cable

(2

(2

×

min 0.5 mm²)

•

Tank Sensor cable

(2

(2

×

min 0.3 mm²)

•

External Controller cable

(2

(2

×

min 0.5 mm²)

•

Solar Three-way Valve cable

(3

(3

×

min 0.5 mm²)

•

Solar Pump Station cable

(2

(2

×

min 0.5 mm²)

Cord/cable list:-

Optional

It is advisable to avoid more than 2 blockage directions.

For better ventilation & multiple-outdoor installation,

please consult authorized dealer/specialist.

This illustration is for explanation purposes only.

The indoor unit will actually face a different way.

35

11.3 Indoor

Unit

11.3.1 How to Fix Installation Plate

The mounting wall is strong and solid enough to prevent

it from vibration.

it from vibration.

Appropriate

Plugs (M8)

Bolt -

size M8

size M8

Washer

Wall

Wall

More than 551

More than 551

Wall

6

6

Indoor

unit

body

unit

body

≥1550 from

ground

ground

Installation

plate 1

Bolt - size M8

Installation

plate

plate

4

0

0

2

0

6

1

71

745

The centre of installation plate should be at more than

551 mm at right and left of the wall.

The distance from installation plate edge to ground

should more than 1550 mm.

551 mm at right and left of the wall.

The distance from installation plate edge to ground

should more than 1550 mm.

Always mount the installation plate horizontally by

aligning the marking thread and using a level gauge.

Mount the installation plate on the wall with 6 sets of

plug, bolt and washer (all non-supply) with size M8.

11.3.2 To Drill a Hole in the Wall and Install

a Sleeve of Piping

1 Insert the piping sleeve to the hole.

2 Fix the bushing to the sleeve.

3 Cut the sleeve until it extrudes about 15 mm

2 Fix the bushing to the sleeve.

3 Cut the sleeve until it extrudes about 15 mm

from the wall.

CAUTION

When the wall is hollow, please be sure to use the sleeve for

tube assembly to prevent dangers caused by mice biting the

connecting cable.

tube assembly to prevent dangers caused by mice biting the

connecting cable.

4 Finish by sealing the sleeve with putty or

caulking compound at the final stage.

15 mm

Putty or caulking compound

ø70 mm

through hole

Indoor

Sleeve

for tube

assembly

Approx. 5 - 7 mm

Bushing for tube

assembly

Wall

Outdoor

11.3.3 Indoor Unit Installation

11.3.3.1

Install the Indoor Unit

1 When connecting solar pump station cable

between indoor unit and solar pump station, the

distance between both apparatuses shall be 2 ~

8 meters and the maximum length of 10 meter

only. Failure to do so may lead to abnormal

operation to the system.

distance between both apparatuses shall be 2 ~

8 meters and the maximum length of 10 meter

only. Failure to do so may lead to abnormal

operation to the system.

2 Engage the slots on the indoor unit to the hooks

of installation plate . Ensure the hooks are

properly seated on the installation plate by

moving it left and right.

properly seated on the installation plate by

moving it left and right.

3 Fix the screws to the holes on the hooks of

installation plate, , as illustrated below.

Slots

Indoor unit (back)

Hooks

Wall

Installation

plate 1

plate 1

Installation

plate

plate

Screws

4

3

11.3.3.2

Water Piping Installation

The minimum requirement of water in the system is

30 litres. If this value could not be achieved, please

install additional buffer tank (field supply).

install additional buffer tank (field supply).

Water inlet and water outlet in indoor unit are used

for connection to water circuit. Please request a

licensed technician to install this water circuit.

licensed technician to install this water circuit.

This water circuit must comply with all relevant

European and national regulations, i.e. IEC/EN

61770.

61770.

Be careful not to deform the piping with excessive

force when doing piping connection job.

Use Rp 1¼" nut for both water inlet and outlet

connection and clean all pipings with tap water

before connecting to the indoor unit.

before connecting to the indoor unit.

Cover the pipe end to prevent dirt and dust when

inserting it through a wall.

Choose proper sealer which can withstand the

pressures and temperatures of the system.

If an existing tank is to be connected to this

indoor/outdoor unit, ensure the pipes are clean

before water pipe installation is carried out.

before water pipe installation is carried out.

36

An external filter (30 mesh or more, field supplied)

must be installed before the water inlet of the indoor

unit (with “WATER IN” indication).

unit (with “WATER IN” indication).

Refer to Diagram 4.1 for pipe connection of

Radiator, Floor Heater, Tank Unit, Solar Pump

Station, 3-way Valve Kit, 2-way Valve Kit and etc.

Fail to connect the pipes appropriately might cause

the unit malfunction.

Station, 3-way Valve Kit, 2-way Valve Kit and etc.

Fail to connect the pipes appropriately might cause

the unit malfunction.

Fan Coil Unit

Radiator/ Floor

Heater

3-Way Valve Kit

(Complete with

Tank Unit)

Tank Unit

Water

Outlet

Water Inlet

Panasonic

Air-to-Water

Heatpump

Indoor Unit

External Filter

(Field Supply)

Solar Pump

Station

(Field supply)

3-Way

Valve Kit

(Field

supply)

Do not install radiator /

floor heater in the

cooling circuit.

Fail to do so might

cause radiator / floor

heater malfunction.

Room Thermostat

(Field Supply)

Space cooling can be achieved

through the fan coil unit ONLY.

Make sure the fan coil unit is

installed in the cooling circuit.

Diagram 4.1: Typical Water Piping Installation

Be sure to use two spanners to tighten the

connection. Tighten the nuts with torque wrench:

117.6 N•m.

117.6 N•m.

If non-brass metallic piping is used for installation,

make sure to insulate the pipes to prevent galvanic

corrosion.

corrosion.

Make sure to insulate the water circuit pipes to

prevent reduction of heating capacity.

After installation, check the water leakage condition

in connection area during test run.

Water Outlet

Water Inlet

CAUTION

Do not over tighten, over tightening cause water leakage.

11.3.3.3 Insulation

Mount the PS foam and long banding strap

to water

inlet and outlet connectors, as shown in below illustration.

Water Connector

PS Foam

7

Water Connector

Long Banding Strap

PS Foam

7

8

11.3.3.4

Indoor Unit Refrigerant Pipe

Installation

Installation

1 Please make flare after inserting flare nut

(located at joint portion of tube assembly) onto

the copper pipe. (In case of using long piping)

the copper pipe. (In case of using long piping)

2 Do not use pipe wrench to open refrigerant

piping. Flare nut may be broken and cause

leakage. Use proper spanner or ring wrench.

leakage. Use proper spanner or ring wrench.

3 Connect the piping:

o

Align the center of piping and sufficiently

tighten the flare nut with fingers.

tighten the flare nut with fingers.

o

Further tighten the flare nut with torque

wrench in specified torque as stated in the

table.

wrench in specified torque as stated in the

table.

Model

Piping size (Torque)

Gas

Liquid

WH-SDC07/09F3E5

WH-UD07/09FE5

ø15.88 mm

(5/8")

[65 N•m]

Ø6.35 mm

(1/4")

[18 N•m]

CAUTION

Do not over tighten, over tightening cause gas leakage.

Liquid Refrigerant Pipe

Gas Refrigerant

Pipe

11.3.3.5

Drain Hose Installation

Use inner diameter 15 mm drain hose in the market.

This hose must to be installed in a continuously

downward direction and in a frost-free environment.

Do not insert this hose into sewage or drain pipe

that may generate ammonia gas, sulfuric gas, etc.

If necessary, use hose clamp to further tighten the

hose at drain hose connector to prevent leakage.

Water will drip from this hose, therefore the outlet of

this hose must be installed in an area where the

outlet cannot become blocked.

outlet cannot become blocked.

Drain water outlet

Drain hose

connector

connector

Drain hose

Click on the first or last page to see other WH-SDC07F3E5 / WH-SDC09F3E5 / WH-UD07FE5 / WH-UD09FE5 service manuals if exist.