LG WFT1100 Service Manual ▷ View online

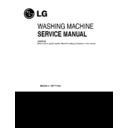

4-1. WIRING DIAGRAM

BA

SE/

LI

N

E

W

IR

IN

G

D

IA

GR

AM

C

O

NT

ROL

LER

A

SM

B

L

R

D

B

L

N

A

B

L

(W

H

)

B

L

(W

H

)

B

N

(BK

)

B

N

(BK

)

B

L

B

L

B

L

B

L

PK

W

H

B

L

(W

H

)

B

L

(W

H

)

B

K

BN

(BK

)

G

N

/Y

L

(G

N

)

B

L

D

R

A

IN

M

O

TO

R

M

O

TO

R

(R

)

W

H

(L

)

YL

YL

R

D

CA

PA

C

IT

O

R

W

H

B

L

D

R

A

IN

PU

M

P

R

D

G

Y

1

2

1

R

D

W

H

H

.V

C

.V

B

L/

W

H

#25

0

R

EC

E

PT

A

C

LE

N

O

TE

S

1

PI

N

H

O

U

SI

N

G

2

PI

N

H

O

U

SI

N

G

3

PI

N

H

O

U

SI

N

G

4

PI

N

H

O

U

SI

N

G

B

L

B

.P.

SEN

S

O

R

1

3

2

O

R

W

H

VL

….

10

3

4

1

2

3

4

1

2

R

.V

W

H

/B

K

O

R

YL

B

L/

W

H

R

D

B

L/

W

H

P/

N

o.

:M

EZ

62

04

330

1

FU

SE

G

Y

PK

4. SERVICE INFORMATION

29

4-2. PROGRAM TIME CHART

Rinse times

Deep rinse addition

Program

Water

Level

Wash

Rinse

1st Deep Rinse

2nd Deep Rinse

3nd Deep Rinse

Spin

Fuzzy

(Normal)

Jean

Extra

Cleaning

Wool

Quick

Wash

Silent

Tub Clean

min sec

sec sec sec sec sec sec sec

sec sec sec

sec sec

sec

c

e

s

n

i

m

n

i

m

n

i

m

n

i

m

n

i

m

n

i

m

n

i

m

n

i

m

n

i

m

n

i

m

min

W

ate

r

Su

pp

y

S

oa

k

W

as

hin

g

D

ra

in

In

te

rm

itt

ent

S

pi

n

N

o

P

ow

er

s

pi

n

S

ho

w

er

D

ra

in

In

te

rm

itt

ent

S

pi

n

Hig

h

Sp

eed

Sp

in

In

te

rm

itt

ent

S

pi

n

W

ate

r

Su

pp

y

R

in

sin

g

D

ra

in

In

te

rm

itt

ent

S

pi

n

N

o

P

ow

er

s

pi

n

W

ate

r

Su

pp

y

R

in

sin

g

D

ra

in

In

te

rm

itt

ent

S

pi

n

N

o

P

ow

er

s

pi

n

W

ate

r

Su

pp

y

R

in

sin

g

D

ra

in

In

te

rm

itt

ent

S

pi

n

Hig

h

Sp

eed

Sp

in

N

o

P

ow

er

s

pi

n

Program

10

9

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

8

7

6

5

4

3

(11)

10

9

8

7

6

5

4

3

2

1

8

7

6

5

4

3

2

1

10

4

3

2

1

3

2

1

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

5

5

3

2

7

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

5

5

3

2

7

7

7

6

6

6

6

5

5

3

3

7

15

15

15

14

14

14

13

13

15

15

14

14

14

13

13

9

9

9

15

15

15

14

14

14

13

13

15

15

14

14

14

13

13

9

9

9

15

15

15

14

14

14

13

13

15

15

14

14

14

13

13

9

9

6

6

6

6

6

6

6

6

2

2

2

2

9

6

6

6

6

6

6

6

6

2

2

2

2

15

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

25

125

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

2

2

5

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

2

2

5

5

5

4

4

4

4

3

3

3

3

5

130

130

120

120

120

120

100

100

100

100

130

130

120

120

120

120

100

100

100

100

130

130

120

120

120

120

100

100

100

100

100

100

100

130

120

120

120

120

100

100

100

100

130

130

120

120

120

120

100

100

100

100

130

130

120

120

120

120

100

100

100

100

100

100

100

90

90

90

80

80

90

90

70

70

90

90

80

80

90

90

70

70

130

130

130

120

120

120

120

100

100

100

100

130

130

120

120

120

120

100

100

100

100

130

130

120

120

120

120

100

100

100

100

130

120

120

120

120

100

100

100

100

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

5

5

3

2

7

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

5

5

3

2

7

7

7

6

6

6

6

5

5

3

3

7

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

2

2

5

5

5

4

4

4

4

3

3

3

3

0

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

2

2

5

5

5

4

4

4

4

3

3

3

3

0

5

5

5

5

5

5

4

4

4

4

5

5

5

5

5

5

4

4

4

4

5

5

5

5

5

5

4

4

4

4

5

5

5

5

5

4

4

4

4

5

5

5

5

5

5

4

4

4

4

5

5

5

5

5

5

4

4

4

4

150

150

150

130

130

130

110

110

100

100

150

150

150

130

130

130

110

110

100

100

150

150

150

130

130

130

110

110

100

100

150

150

150

130

130

130

110

110

150

150

130

130

130

110

110

100

100

150

150

150

130

130

130

110

110

100

100

150

150

150

130

130

130

110

110

100

100

150

150

150

130

130

130

110

110

90

90

70

70

90

70

70

150

150

150

150

130

130

130

110

110

100

100

150

150

150

130

130

130

110

110

100

100

80

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

5

5

5

4

4

4

4

3

3

3

3

5

5

4

4

4

4

3

3

3

3

130

130

120

120

120

120

100

100

100

100

130

130

120

120

120

120

100

100

100

100

100

100

100

130

120

120

120

120

100

100

100

100

130

130

120

120

120

120

100

100

100

100

100

100

100

90

900

90

80

80

80

80

130

130

130

120

120

120

120

100

100

100

100

130

130

120

120

120

120

100

100

100

100

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

7

7

7

6

6

6

6

5

5

3

3

7

7

6

6

6

6

5

5

3

3

5

5

4

4

4

4

3

3

3

3

5

4

4

4

4

3

3

3

3

7

7

6

6

6

6

5

5

3

3

7

6

6

6

6

5

5

3

3

130

130

120

120

120

120

100

100

100

100

130

120

120

120

120

100

100

100

100

120

30 60 60 20

120

120

60

60

120

120

120

60

120

3

3

3

3

3

120

3

3

3

3

3

3

200

200

200

60

102

200

200

30

4-3. ADJUSTMENT

1) Brake lever adjustment

•

Shown as in the figure, untighten the adjustment

screw to keep clearance less than 1.9°æ0.1mm

between the tip and the brake lever.

And turn on the lock nut then paint it red.

•

Painting part is adjusted in factory, it does not

need adjusting.

•

Adjust the screw properly if the brake doesn't

work during spin.

CAUTION

2) Keeping clearance

•

Keep the clearance about 2.0~3.5mm between

brake lever and P.V link as shown in the figure.

•

Clutch pulley must be turning to one side P.V

Link is pulling the brake Lever.

•

Clutch pulley must be turning to the left and the

right when P.V Linke does not pull the brake

Lever.

CAUTION

3) V-belt adjustment

•

Adjust the motor pulley by pushing the motor like

arrow , to make V-belt tension parallel when

pushed at the point of arrow .

•

When the V-belt is not properly adjusted, the

motor will not be running or the belt will be

slipping.

CAUTION

31

4-4. DISASSEMBLY INSTRUCTION

Be sure to unplug the power to repair and

replace electric parts.

1) Disassembly of Front Panel

& PCB Assembly

Remove two screw caps using a sharp tool

and two front panel fixing screws.

Push the front panel to the left side then

Push the front panel to the left side then

pull it out.

Disconnect the leads from the controller.

Remove 6 screw from the front panel.

Disconnect the leads from the controller.

Remove 6 screw from the front panel.

Remove the PCB Assembly.

Fuse is located in the PCB assembly For fuse

replacement use the following rated fuse

* Rating of fuse

- 250V 6A fusing type for 220-240V product

- 125V 12A fusing type for 100-127V product

leads

PCB Assembly

Fuse

Be sure to make earth connection for trouble

diagnosis and parts replacement. If impossible,

touch earth wire on the body to remove electric

deviation between the body and product before

work.

CAUTION FOR ELECTROSTATICS

32

Click on the first or last page to see other WFT1100 service manuals if exist.