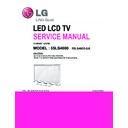

LG 55LS4600 / 55LS460E (CHASSIS:LA21B) Service Manual ▷ View online

- 13 -

5.2. Option selection per country

5.2.1. Overview

(1) Tool option selection is only done for models in Non-USA

(2) Applied model: LA02D and LA02E Chassis applied to

CANADA and MEXICO

5.2.2. Country Group selection

(1) Press ADJ key on the Adj. R/C, and then select Country

Group Menu

(2) Depending on destination, select KR or US, then on the

lower Country option, select US, CA, MX.

Selection is done using +, - KEY

5.2.3. Tool Option inspection

▪ Press Adj. key on the Adj. R/C, then select Tool option.

Model

Module

Tool 1

Tool 2

Tool 3

Tool 4

Tool 5

47LM4600-UA

LGD

32855

2423

10523 29612

7170

55LM4600-UA

LGD

32857

2423

11547

29612

7170

32LS5600-UA

LGD

16725

2423

10523 29612

7202

37LS5600-UC

LGD

16725

2423

9499

29612

7202

47LS5600-UC

AUO

20823

2423

9499

29612

7218

55LS5600-UC

LGD

20825

2423

9499

29612

7170

55LS5600-UC

AUO

20825

2423

9499

29612

7218

6. GND and HI-POT Test

6.1. GND & HI-POT auto-check preparation

(1) Check the POWER CABLE and SIGNAL CABE insertion

condition

6.2. GND & HI-POT auto-check

(1) Pallet moves in the station. (POWER CORD / AV CORD is

tightly inserted)

(2) Connect the AV JACK Tester.

(3) Controller (GWS103-4) on.

(4) GND Test (Auto)

- If Test is failed, Buzzer operates.

- If Test is passed, execute next process (Hi-pot test).

(Remove A/V CORD from A/V JACK BOX)

(5) HI-POT test (Auto)

- If Test is failed, Buzzer operates.

- If Test is passed, GOOD Lamp on and move to next process

automatically.

6.3. Checkpoint

(1) Test voltage

- GND: 1.5KV/min at 100mA

- SIGNAL: 3KV/min at 100mA

(2) TEST time: 1 second

(3) TEST POINT

- GND Test = POWER CORD GND and SIGNAL CABLE GND.

- Hi-pot Test = POWER CORD GND and LIVE & NEUTRAL.

(4) LEAKAGE CURRENT: At 0.5mArms

7. AUDIO output check

7.1. Audio input condition

(1) RF input: Mono, 1KHz sine wave signal, 100% Modulation

(2) CVBS, Component: 1KHz sine wave signal (0.4Vrms)

(3) RGB PC: 1KHz sine wave signal (0.7Vrms)

7.2. Specification

No

Item

Min

Typ

Max

Unit

Remark

1

Audio

practical

max Output,

L/R

practical

max Output,

L/R

9.0

8.5

8.5

10.0

8.9

12.0

9.9

W

Vrms

(1) Measurement

condition

- EQ/AVL/Clear

Voice: Off

(2) Speaker (8Ω

Impedance)

8. EYE-Q Check

Step 1) Turn on the TV..

Step 2) Press 'EYE button' on the adjustment remote-

controller.

Step 3) Cover 'Eye Q sensor' on the front of set with your

hands, hold it for 6 seconds.

Step 4) Check "the Sensor Data" on the screen, make certain

that Data is below 10. If Data isn’t below 10 in 6

seconds, Eye Q sensor would be bad. You should

change Eye Q sensor.

Step 5) Uncover your hands from Eye Q sensor, hold it for 6

seconds.

Step 6) Check "Back Light(xxx)" on the screen, check data

increase . You should change Eye Q sensor.

<Step 2>

<Step 5>

<Step 6>

<Step 3>

<Step 4>

- 14 -

9. USB S/W Download

(optional, Service only)

(1) Put the USB Stick to the USB socket

(2) Automatically detecting update file in USB Stick

- If your downloaded program version in USB Stick is lower

than that of TV set, it didn’t work. Otherwise USB data is

automatically detected.

(3) Show the message “Copying files from memory”

(5) Updating Completed, The TV will restart automatically

(6) If your TV is turned on, check your updated version and

Tool option.

* If downloading version is more high than your TV have, TV

can lost all channel data. In this case, you have to channel

recover. If all channel data is cleared, you didn’t have a DTV/

ATV test on production line.

* After downloading, TOOL OPTION setting is needed again.

(1) Push "IN-START" key in service remote controller.

(2) Select "Tool Option 1" and Push “OK” button.

(3) Punch in the number. (Each model has their number.)

(4) Updating is staring.

- 15 -

SCREW ASSEMBLY WORKING GUIDE

• FAB31339402

(M3*L4.5, BK, Machine)

• 14EA

• FAB31339201

(M3*L10, BK, Taptite)

• 9EA

• FAB30016122

(M4*L20, BK, Taptite)

• 4EA

D

D

D

D

D

D

D

D

D

D

D

D

■ Screw specification and application situation

C

A

A

A

A

A

A

A

A

A

A

A

A

B

C

C

C

C

C

C

C

• FAB30078812

(M6*L10, BK, Machine)

4EA

4EA

B

B

B

A

A

C

C

C

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

B

B

C

C

C

C

C

C

C

C

C

C

C

C

C

C

• FAB30078812

(M6*L10, BK, Machine)

4EA

4EA

B

B

B

B

B

B

A

A

A

A

C

A

C

※

Warning

Check Screw Type When Screw is assembled

at Part. If Screw is used at the part

Module will get damaged

at Part. If Screw is used at the part

Module will get damaged

A

A

C

※

Warning

Check Screw Type When Screw is assembled

at Part. If Screw is used at the part

Module will get damaged

at Part. If Screw is used at the part

Module will get damaged

A

- 16 -

TROUBLE SHOOTING

1. Power-up boot check

Check stand-by Voltage.

P403 9~12pin : +3.5V_ST

Check Power connector

Main B/D 3.5V Line

Short Check

Check X201 clock

24 MHz

Replace X201

Check P403 PWR_ON.

1pin : 3.3V

Replace Mstar(IC101) or Main board

Check Multi Voltage

P403 2pin:24V ,17pin:12V

Replace Power Board

Check Inverter Control & Error Out

P403 18 pin : High

P403 24 pin : low

Check Power Board or Module

Check IC402/3/7 Output Voltage

IC402 : 2.5V

IC403 : 1.1V

IC407 : 1.5V

Q403 : 3.3V

Replace IC402/3/7, Q403

Re-download software.

Check Micom Voltage

L404 : +3.5V

Replace L404

Check LVDS Power Voltage

Q409 : 12V

Replace Q409

Check Mstar LVDS Output

Replace Mstar(IC101) or Main Board

Change Module

ok

ok

ok

ok

ok

ok

ok

ok

ok

No

No

ok

Replace Power board.

ok

No

No

No

No

No

No

No

No

Click on the first or last page to see other 55LS4600 / 55LS460E (CHASSIS:LA21B) service manuals if exist.