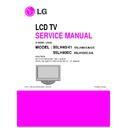

LG 55LH40 / 55LH41 / 55LH400С (CHASSIS:LA92B) Service Manual ▷ View online

4. Updating is staring.

5. Updating Completed, The TV will restart automatically.

6. If your TV is turned on, check your updated version and

Tool option. (explain the Tool option, next stage)

6. If your TV is turned on, check your updated version and

Tool option. (explain the Tool option, next stage)

* If downloading version is more high than your TV have, TV

can lost all channel data. In this case, you have to channel

recover. if all channel data is cleared, you didn’t have a

DTV/ATV test on production line.

can lost all channel data. In this case, you have to channel

recover. if all channel data is cleared, you didn’t have a

DTV/ATV test on production line.

* After downloading, have to adjust TOOL OPTION again.

1. Push "IN-START" key in service remote controller.

2. Select "Tool Option 1" and Push “OK” button.

3. Punch in the number. (Each model has their number.)

4. Completed selecting Tool option.

1. Push "IN-START" key in service remote controller.

2. Select "Tool Option 1" and Push “OK” button.

3. Punch in the number. (Each model has their number.)

4. Completed selecting Tool option.

4. Board-level adjustment

4.1 Board-level adjustment

• Adjust 480i Comp1 adj.(Comp1080i & RGB Adjust use internal

pattern).

• EDID/DDC download

Above adjustment items can be also performed in Final

Assembly if needed. Both Board-level and Final assembly

adjustment items can be check using In-Start Menu 1. Adjust

Check.

Above adjustment items can be also performed in Final

Assembly if needed. Both Board-level and Final assembly

adjustment items can be check using In-Start Menu 1. Adjust

Check.

* After Board level adjustment, set volume setting value 0

4.2 Final assembly adjustment

•White Balance adjustment

•RS-232C functionality check

•Factory Option setting per destination

•Ship-out mode setting (In-Stop)

•RS-232C functionality check

•Factory Option setting per destination

•Ship-out mode setting (In-Stop)

4.3 Etc.

•Ship-out mode

•Service Option Default

•USB Download(S/W Update, Option)

•Service Option Default

•USB Download(S/W Update, Option)

5. Board-level adjustment

5.1 ADC adjustment

5.1.1 Overview

ADC adjustment is needed to find the optimum black level

and gain in Analog-to-Digital device and to compensate

RGB deviation.

and gain in Analog-to-Digital device and to compensate

RGB deviation.

5.1.2 Equipment & Condition

1) Jig (RS-232C protocol)

2) Input : MSPG-925FS(Model : 209 ,Pattern : 65, Only

2) Input : MSPG-925FS(Model : 209 ,Pattern : 65, Only

component))

3) RGB Adjust use internal pattern.5.1.3 Adjustment

5.1.3 Adjustment

5.1.2.1 Method

• Using RS-232, adjust items listed in 3.1 in the order shown

in 5.1.2.3 Adj. protocol

in 5.1.2.3 Adj. protocol

Ref.) ADC adj. RS232C Protocol_Ver1.0

5.1.2.3 Adj. order

•ad 00 00 [Enter ADC adj. mode]

•ad 00 10 [Adjust 480i Comp1/1080i Comp1/1024*768 RGB]

•ad 00 90 End adj.

•ad 00 10 [Adjust 480i Comp1/1080i Comp1/1024*768 RGB]

•ad 00 90 End adj.

- 17-

C

2009

Model

Tool option1 Tool option2

Tool option3

Tool option4

47LH55-UA

33281

3400

35748

1024

55LH55-UA

45569

3400

35748

1024

55LH40-UA

45313

3400

35748

1024

Protocol

Command

Set ack

Enter adj.

ad 00 00

d 00 OK00x

mode

Begin adj.

ad 00 10

Return adj.

OKx (Success)

result

NGx (Fail)

Read adj.

(main)

(main)

data

ad 00 20

000000000000000000000000007c007b006dx

(sub )

(Sub)

ad 00 21

000000070000000000000000007c00830077x

Confirm adj.

ad 00 99

NG 03 00x (Fail)

NG 03 01x (Fail)

NG 03 02x (Fail)

OK 03 03x (Success)

End adj.

ad 00 90

d 00 OK90x

6. Final Assembly adjustment

6.1 White Balance adjstment

6.1.1 Overview

•W/B adj.: Objective & How-it-works

- Objective: To reduce each Panel’s W/B deviation

- How-it-works: When R/G/B gain in the OSD is at 192, it

means the panel is at its Full Dynamic Range. In order to

prevent saturation of Full Dynamic range and data, one of

R/G/B is fixed at 192, and the other two is lowered to find the

desired value.

- Objective: To reduce each Panel’s W/B deviation

- How-it-works: When R/G/B gain in the OSD is at 192, it

means the panel is at its Full Dynamic Range. In order to

prevent saturation of Full Dynamic range and data, one of

R/G/B is fixed at 192, and the other two is lowered to find the

desired value.

6.1.2 Equipment

1) Color Analyzer : CA-210 (NCG: CH 9 / WCG: CH12 /LED

Module:CH14)

2) Adjustment Computer (During auto adj., RS-232C protocol

is needed)

3) Adjustment R/C

4) Video Signal Generator MSPG-925F 720p/216Gray

(Model:217, Pattern:78)

-> Only when internal pattern is not available

• Color Analyzer Matrix should be calibrated using CS-1000

Module:CH14)

2) Adjustment Computer (During auto adj., RS-232C protocol

is needed)

3) Adjustment R/C

4) Video Signal Generator MSPG-925F 720p/216Gray

(Model:217, Pattern:78)

-> Only when internal pattern is not available

• Color Analyzer Matrix should be calibrated using CS-1000

6.1.3 Equipment connection map

• Protocol

<Command Format>

<Command Format>

- LEN: Number of Data Byte to be send

- CMD: Command

- VAL: FOS Data

- CS: Checksum of sent Data

- A: Acknowledge

Ex) [Send: JA_00_DD] / [Ack: A_00_okDDX]

- CMD: Command

- VAL: FOS Data

- CS: Checksum of sent Data

- A: Acknowledge

Ex) [Send: JA_00_DD] / [Ack: A_00_okDDX]

• RS-232C Command used during auto-adjustment

Ex) wb 00 00 -> Begin white balance auto-adj.

wb 00 10 -> Gain adj.

ja 00 ff -> Adj. data

jb 00 c0

...

...

wb 00 1f -> Gain adj. complete

*(wb 00 20(Start), wb 00 2f(End)) -> Off-set adjustment

ja 00 ff -> Adj. data

jb 00 c0

...

...

wb 00 1f -> Gain adj. complete

*(wb 00 20(Start), wb 00 2f(End)) -> Off-set adjustment

wb 00 ff -> End white balance auto-adjustment

6.1.4 Adjustment method

6.1.4.1 Auto adjustment method

1) Set TV in adj. mode using POWER On Key

2) Zero calibrate probe then place it on the center of the

Display

3) Connect Cable(RS-232C)

4) Select mode in adj. Program and begin adj.

5) When adj. is complete (OK Sign), check adj. status per

4) Select mode in adj. Program and begin adj.

5) When adj. is complete (OK Sign), check adj. status per

mode (Warm, Medium, Cool)

6) Remove probe and RS-232C cable to complete adj.

• adj. must begin w/ command “Wb 00 00”, and end w/”wb 00

ff” and adjustment offset if needed.

6.1.4.2 Manual adj. method

Dynamic contrast : off

Dynamic color : off

OPC : Off

Energy saving mode : Off

Dynamic color : off

OPC : Off

Energy saving mode : Off

1) Set TV in adj. mode using POWER On Key

2) Press ADJ key Æ EZ adjust using adj. R/C

3) Using CH + / - KEY, select 7.TEST PATTERN then press

2) Press ADJ key Æ EZ adjust using adj. R/C

3) Using CH + / - KEY, select 7.TEST PATTERN then press

Enter to place inHEAT RUN mode and wait for 5 minutes.

4) Zero calibrate the probe of Color Analyzer, then place iton

the center of LCD module within 10 cm of the surface.

5) Press ADJ key Æ 6. White-Balance then press the cursor

to the right (KEY

)

(When

is pressed Full White internal pattern will be

displayed)

6) One of R Gain / G Gain / B Gain should be fixed at 192,

and the rest will be lowered to meet the desired value.

7) Adjustment is performed in COOL, MEDIUM, WARM 3

modes of color temperature

• If internal pattern is not available, use RF input(Full white

216 gray) In EZ Adjustment menu 6.White Balance, you can

select one of 2 options: Test pattern ON, Test pattern OFF.

Default is “ON” By selecting “OFF”, you can adjust using RF

signal.

select one of 2 options: Test pattern ON, Test pattern OFF.

Default is “ON” By selecting “OFF”, you can adjust using RF

signal.

• Adjustment condition and cautionary items

1) Lighting condition in surrounding area Surrounding lighting

should be lower than 10 lux.

Try to isolate adj. area into dark surrounding.

2) Probe location

- Color Analyzer (CA-210) probe should be within 10cm

and perpendicular of the module surface (80°~ 100°)

- B/L on should be checked using no signal or Full white

Pattern

6.1.5 Reference

(White Balance adj. coordinate and color temperature)

• Luminance: Full white 216 Gray

• Standard color coordinate and temperature using CS-1000

• Standard color coordinate and temperature using CS-1000

- 18 -

C

2009

Color Analyzer

Computer

RS-232C

# Pattern Generator

* If TV internal pattern is used,not needed

Signal Source

Probe

RS-232C

RS-232C

START 6E A 50 A

LEN A 03 A

CMD A 00 A

VAL A CS A

STOP

CMD

ID DATA

Explanation

wb

00

00

Begin White Balance adj.

wb

00

ff

End White Balance adj.

(internal pattern disappears)

Coordinate

Mode

x

y

Temp

uv∆

Cool

0.276

0.283

11000K

0.0000

Medium

0.285

0.293

9300K

0.0000

Warm

0.313

0.329

6500K

0.0000

C

2009

- 19 -

• 55LH40-UA, 47/55LH55-UA (N-America)

Standard color coordinate and temperature using CA-

210(CH 09)

210(CH 09)

6.2 Option selection per country

6.2.1 Overview

America due to rating

• Applied model: LA92B Chassis applied None USA

Model(Canada, Mexico)

6.2.2 Method

1) Press ADJ key on the Adjustment R/C, then select Country

Group Menu

2) Depending on destination, select KR or US, then on the

lower option, select US, CA, MX. Selection is done using +,

- KEY

- KEY

6.3 EYE-Q function check

Step 1) Turn on TV

Step 2) Press EYE key of Adj. R/C

Step 3) Cover the Eye Q II sensor on the front of the using

Step 2) Press EYE key of Adj. R/C

Step 3) Cover the Eye Q II sensor on the front of the using

your hand and wait for 6 seconds

Step 4) Confirm that R/G/B value is lower than 10 of the “Raw

Data (R: G: B: )” .

If after 6 seconds, R/G/B value is not lower than 10,

replace Eye Q II sensor

replace Eye Q II sensor

Step 5) Remove your hand from the Eye Q II sensor and wait

for 6 seconds

Step 6) Confirm that “B. Light(xxx)” value increases from 0.

If change is not seen, replace Eye Q II sensor

< step 2> < step 3> < step 4>

< step 5> < step 6>

- Check that Power Cord is fully inserted to the set

(If loose, re-insert)

- Unit w/ fully inserted power cord and A/V arrives to the auto-

check process.

- Connect D-terminal AV JACK TESTER

- Auto CONTROLLER(GWS103-4) ON

- Perform GND TEST

- If NG, Buzzer will sound to inform the operator

- If OK, changeover to I/P check automatically

- Auto CONTROLLER(GWS103-4) ON

- Perform GND TEST

- If NG, Buzzer will sound to inform the operator

- If OK, changeover to I/P check automatically

(Remove CORD,A/V from AV Jack Box)

- Perform I/P test

- If NG, Buzzer will sound to inform the operator

- If OK, Good lamp will lit up and the stopper will allow the

- If NG, Buzzer will sound to inform the operator

- If OK, Good lamp will lit up and the stopper will allow the

pallet to move on to next process.

7.2 Checkpoint

NEUTRAL

• LEAKAGE CURRENT: At 0.5mArms

Coordinate

Mode

x

y

Temp

uv∆

Cool

0.276±0.002

0.283±0.002

11000K

0.0000

Medium 0.285±0.002

0.293±0.002

9300K

0.0000

Warm

0.313±0.002

0.329±0.002

6500K

0.0000

Green Eye-Check

Sensor Data:

1

Backlight: 0

O.K

Green Eye-Check

Sensor Data: 215

Backli ght : 100

C

2009

- 20 -

• VIDEO PATH

VIDEO TROUBLESHOOTING

SIDE

SIDE

JA

C

K

P

A

C

K

JA

C

K

P

A

C

K

D-sub RGB

HDMI 1

Side

A

V

CV

BS

,

L

/R

RS-232C (Ctrl./SVC)

RGB/

H

/V

Half-NIM Tuner

MAX3

232

Saturn5

Saturn5

(ATSC US)

(ATSC US)

LGE3159

MPEG2

L

inux

Scal

er

IF

+/-

SIF

TU_CVBS

R

e

set / IF

_AGC

…

SDA

/SCL_

5

V

HDMI4

HDMI 2

RX

/T

X

R

X

/TX

RE

A

R

RE

A

R

JA

C

K

P

A

C

K

JA

C

K

P

A

C

K

T

R

B

uffer

VS

B

D

e

m

od.

T

S

In[0…

7]

TS_

cl

k, SOP, Va

l

EEPR

OM

AV

Compone

nt 1

Y

Pb

Pr, L/R

CV

BS

,

Y/

C,

L

/R

Compone

nt 2

Y

Pb

Pr, L/R

SCL

,

SDA

_3

.3

V

LCD

Module

(FHD+120Hz)

(F

H

D

+

T

ru

m

o

tion240

H

z

)

FRC IC

(L

GE7329)

DDR2

Qimonda/Hy

nix

FRC Block

FRC Block

LV

D

S

HDMI 3

HDMI S/W

Click on the first or last page to see other 55LH40 / 55LH41 / 55LH400С (CHASSIS:LA92B) service manuals if exist.