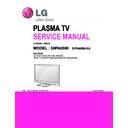

LG 50PA6500-SA (CHASSIS:PB21A) Service Manual ▷ View online

- 2 -

CONTENTS .............................................................................................. 2

SAFETY PRECAUTIONS ........................................................................ 3

SPECIFICATION ....................................................................................... 4

ADJUSTMENT INSTRUCTION ................................................................ 5

BLOCK DIAGRAM .................................................................................. 12

EXPLODED VIEW .................................................................................. 13

SCHEMATIC CIRCUIT DIAGRAM ..............................................................

CONTENTS

- 3 -

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An

isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1 W), keep the resistor 10 mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an

AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1 M

Ω and 5.2 MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Leakage Current Hot Check

(See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5 K / 10 watt resistor in parallel with a 0.15 uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5 mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

IMPORTANT SAFETY NOTICE

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

0.15u

SAFETY PRECAUTIONS

- 4 -

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement.

1. Application range

This spec sheet is applied all of the PDP TV with PB21A chassis.

2. Requirement for Test

Each part is tested as below without special appointment.

(1) Temperature: 25 °C ± 5 °C(77 °F ± 9 °F), CST: 40 °C ± 5 °C

(2) Relative Humidity: 65 % ± 10 %

(3) Power Voltage

: Standard input voltage (AC 100-240 V~, 50/60 Hz)

* Standard Voltage of each products is marked by models.

(4) Specification and performance of each parts are followed each drawing and specification by part number in accordance with

BOM.

(5) The receiver must be operated for about 5 minutes prior to the adjustment.

3. Test method

(1) Performance: LGE TV test method followed

(2) Demanded other specification

- Safety : CE, IEC specification

- EMC : CE, IEC

4. Model General Specification

No

Item

Specification

Remark

1

Receiving System

1) SBTVD / NTSC / PAL-M / PAL-N

50A6500-SA

50A4900-SA

2) DVB-T

42/50PA4500-DF

2

Available Channel

1) VHF : 02~13

2) UHF : 14~69

3) DTV : 07-69 (VHF high/UHF)

4) CATV : 02~135

50A6500-SA

50A4900-SA

1) VHF : 02~13

2) UHF : 14~69

3) DTV : 14~69 (UHF)

4) CATV : 02~135

42/50PA4500-DF

3

Input Voltage

1) AC 100 ~ 240V 50/60Hz

4

Market

Brazil / chile / Peru / Venezuela / Costarica / Uruguay

5

Screen Size

42 inch Wide(1024 × 768)

50 inch Wide(1024 × 768)

50 inch Wide(1920 × 1080)

60 inch Wide(1920 × 1080)

42PA all model

50PA4 all model

50PA6 all model

60PA6 all model

6

Aspect Ratio

16:9

7

Tuning System

FS

8

Module

PDP42T4#### (1024 × 768)

PDP50T4#### (1024 × 768)

PDP50R4#### (1920 × 1080)

PDP60R4#### (1920 × 1080)

42PA all model

50PA4 all model

50PA6 all model

60PA6 all model

9

Operating Environ-

ment

1) Temp : 0 ~ 40 deg

2) Humidity : ~ 80 %

10

Storage Environ-

ment

1) Temp : -20 ~ 60 deg

2) Humidity : ~ 85 %

- 5 -

ADJUSTMENT INSTRUCTION

1. Application Range

This spec. sheet applies to PB21A chassis applied PDP TV all

models manufactured in TV factory.

2. Specification

(1) Because this is not a hot chassis, it is not necessary to

use an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order. But it is

flexible when its factory local problem occurs.

(3) T he adjustment must be performed in the circumstance of

25 °C ± 5 °C of temperature and 65 % ± 10 % of relative

humidity if there is no specific designation.

(4) The input voltage of the receiver must keep AC 100-240

V~, 50/60 Hz.

(5) Before adjustment, execute Heat-Run for 5 minutes.

■ After Receive 100% Full white pattern (06CH) then

process Heat-run

(or “8. Test pattern” condition of Ez-Adjust status)

■ How to make set white pattern

1) Press Power ON button of Service Remocon

2) Press ADJ button of Service remocon. Select “10. Test

pattern” and, after select “White” using navigation

button, and then you can see 100% Full White pattern.

* In this status you can maintain Heat-Run useless any

pattern generator

* Notice: if you maintain one picture over 20 minutes

(Especially sharp distinction black with white

pattern – 13Ch, or Cross hatch pattern – 09Ch)

then it can appear image stick near black level.

3. Adjustment items

3.1. PCB Assembly adjustment

■ Adjust 480i Comp1

■ Adjust 1080p Comp1/RGB

● If it is necessary, it can adjustment at Manufacture Line

● You can see set adjustment status at “9. ADJUST

CHECK” of the “In-start menu”

3.2. Set Assembly Adjustment

■ EDID (The Extended Display Identification Data )

■ Color Temperature (White Balance) Adjustment

■ Make sure RS-232C control

■ Selection Factory output option

4. PCB Assembly Adjustment

4.1. Using RS-232C

- Adjust 3 items at 3.1. PCB assembly adjustments

" 4.1. ■ Adjustment sequence" one after the order.

■ Adjustment sequence

■ Necessary items before Adjustment items

● Pattern Generator : (MSPG-925FA)

● Adjust 480i comp1

(MSPG-925FA:model :209, pattern :65) - comp1 Mode

● Adjust 1080p comp1

(MSPG-925FA:model :225 , pattern :65) - comp1 Mode

● Addjust RGB (MSPG-925FA:model :225 , pattern :65)

- RGB-Pc Mode

* If you want more information then see the below Adjustment

method (Factory Adjustment)

■ Adjustment sequence

● aa 00 00: Enter the ADc Adjustment mode.

● xb 00 40: change the mode to component1 (No actions)

● ad 00 10: Adjust 480i comp

● ad 00 10: Adjust 1080p comp

● xb 00 60: change to RGB-Pc mode(No action)

● ad 00 10: Adjust 1080p RGB

● xb 00 90: Endo of Adjustmennt

Order

command

Set response

1. Inter the

Adjustment

mode

aa 00 00

a 00 OK00x

2. Change the

Source

XB 00 40

XB 00 60

b 00 OK40x (Adjust 480i Comp1 )

(Adjust 1080p Comp1)

b 00 OK60x (Adjust 1080p RGB)

3.Start Adjustment ad 00 10

4. Return the

4. Return the

Response

OKx ( Success condition )

NGx ( Failed condition )

5. Read

Adjustment

data

( main )

ad 00 20

( main )

ad 00 30

(main : component1 480i, RGB 1080p)

000000000000000000000000007c007b-

006dx

(main : component1 1080p)

000000070000000000000000007c0083

0077x

6. Confirm

Adjustment

ad 00 99

NG 03 00x (Failed condition)

NG 03 01x (Failed condition)

NG 03 02x (Failed condition)

OK 03 03x (Success condition)

7. End

of Adjustment

ad 00 90

d 00 OK90x

< See ADc Adjustment RS232c Protocol_Ver1.0 >