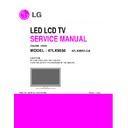

LG 47LX9550-CA (CHASSIS:LC03M) Service Manual ▷ View online

- 9 -

- Adjust sequence

A

Press the PIP key of the ADJ remote control. (This PIP

key is hot key to enter the VCOM adjusting mode)

key is hot key to enter the VCOM adjusting mode)

(Or After enter Service Mode by pushing “ADJ” key, then

Enter V-Com Adjust mode by pushing “

Enter V-Com Adjust mode by pushing “

G

” key at “12. V-

Com”)

A

As pushing the right or the left button on the remote

control, And find the V-COM value Which is no or

minimized the Flicker.

control, And find the V-COM value Which is no or

minimized the Flicker.

(If there is no flicker at default value, Press the exit key

and finish the VCOM adjustment.)

and finish the VCOM adjustment.)

A

Push the OK key to store value. Then the message

“Saving OK” is pop.

“Saving OK” is pop.

A

Press the exit key to finish VCOM adjustment.

3.6. Model name & serial number download

(1) Model name & Serial number D/L

A

Press “Power on” key of service remote control.(Baud

rate : 115200 bps)

rate : 115200 bps)

A

Connect RS232 Signal Cable to RS-232 Jack.

A

Write Serial number by use RS-232.

A

Must check the serial number at Instart menu.

(2) Method & notice

A. Serial number download is using of scan equipment.

B. Setting of scan equipment operated by Manufacturing

B. Setting of scan equipment operated by Manufacturing

Technology Group.

C. Serial number download must be conformed when it is

produced in production line, because serial number

download is mandatory by D-book 4.0

download is mandatory by D-book 4.0

* Manual Download (Model Name and Serial Number)

If the TV set is downloaded by OTA or service man,

sometimes model name or serial number is initialized.(Not

always)

There is impossible to download by bar code scan, so It

need Manual download.

a. Press the ‘instart’ key of ADJ remote control.

b. Go to the menu ‘5.Model Number D/L’ like below photo.

c. Input the Factory model name(ex 42LE5500-CA) or Serial

sometimes model name or serial number is initialized.(Not

always)

There is impossible to download by bar code scan, so It

need Manual download.

a. Press the ‘instart’ key of ADJ remote control.

b. Go to the menu ‘5.Model Number D/L’ like below photo.

c. Input the Factory model name(ex 42LE5500-CA) or Serial

number like photo.

d. Check the model name Instart menu -> Factory name

displayed (ex 42LE7500-CB)

e. Check the Diagnostics (DTV country only) -> Buyer model

displayed (ex 42LE7500-CB)

4. Manual Adjustment

4.1. ADC(GP2) Adjustment

4.1.1. Overview

ADC adjustment is needed to find the optimum black level and

gain in Analog-to-Digital device and to compensate RGB

deviation.

gain in Analog-to-Digital device and to compensate RGB

deviation.

4.1.2. Equipment & Condition

1) Adjust Remocon

2) 801GF(802B, 802F, 802R) or MSPG925FA Pattern Generator

2) 801GF(802B, 802F, 802R) or MSPG925FA Pattern Generator

- Resolution :

480i, 720*480 (MSPG-925FA -> Model: 209, Pattern: 65)

- 480i

1080p, 1920*1080 (MSPG-925FA -> Model: 225, Pattern:

65) - 1080p

- 480i

1080p, 1920*1080 (MSPG-925FA -> Model: 225, Pattern:

65) - 1080p

- Pattern : Horizontal 100% Color Bar Pattern

- Pattern level: 0.7 ± 0.1 Vp-p

- Image

- Pattern level: 0.7 ± 0.1 Vp-p

- Image

3) Must use standard cable

4.1.3. Adjust method

(1) ADC 480i, 1080p Comp1

1) Check connected condition of Comp1 cable to the equipment

2) Give a 480i, 1080p Mode, Horizontal 100% Color Bar

2) Give a 480i, 1080p Mode, Horizontal 100% Color Bar

Pattern to Comp1.

(MSPG-925FA -> Model: 209, Pattern: 65) - 480i

(MSPG-925FA -> Model: 225, Pattern: 65) - 1080p

(MSPG-925FA -> Model: 225, Pattern: 65) - 1080p

3) Change input mode as Component1 and picture mode

as “Standard”

4) Press the In-start Key on the ADJ remote after at least 1

min of signal reception. Then, select 7. External ADC ->

1. COMP 1080p on the menu. Press enter key. The

adjustment will start automatically.

1. COMP 1080p on the menu. Press enter key. The

adjustment will start automatically.

5) If ADC calibration is successful, “ADC RGB Success” is

displayed. If ADC calibration is failure, “ADC RGB Fail”

is displayed.

is displayed.

6) If ADC calibration is failure, after recheck ADC pattern or

condition retry calibration Error message refer to 5).

(2) ADC 1920*1080 RGB

1) Check connected condition of Component & RGB cable

to the equipment.

2) Give a 1920*1080 Mode, 100 % Horizontal Color Bar

Pattern to RGB port.

(MSPG-925 Series -> model: 126 , pattern: 65 )

3) Change input mode as RGB and picture mode as

“Standard”.

4) Press the In-start Key on the ADJ remote after at least 1

min of signal reception. Then, select 7. External ADC ->

1. COMP 1080p on the menu. Press enter key. The

adjustment will start automatically.

1. COMP 1080p on the menu. Press enter key. The

adjustment will start automatically.

5) If ADC calibration is successful, “ADC RGB Success” is

displayed. If ADC calibration is failure, “ADC RGB Fail”

is displayed.

is displayed.

6) If ADC calibration is failure, after recheck ADC pattern or

condition retry calibration Error message refer to 5).

[Visual Adjust and control the Voltage level]

Model

V-CAM default value

42LE8500

435

- 10 -

4.2.

EDID(The Extended Display Identification

Data)/DDC(Display Data Channel) download

(1) Overview

It is a VESA regulation. A PC or a MNT will display an

optimal resolution through information sharing without any

necessity of user input. It is a realization of “Plug and Play”.

(2) Equipment

- Adjust remote control

- Since embedded EDID data is used, EDID download JIG,

HDMI cable and D-sub cable are not need.

(3) Download method

1) Press Adj. key on the Adj. R/C, then select “10.EDID

D/L”, By pressing Enter key, enter EDID D/L menu.

2) Select [Start] button by pressing Enter key, HDMI1 /

HDMI2 / HDMI3 / HDMI4 / RGB are Writing and display

OK or NG.

4.3. White Balance Adjustment

4.3.1 Overview

(1) W/B adj. Objective & How-it-works

(2) Objective: To reduce each Panel’s W/B deviation

(3) How-it-works : When R/G/B gain in the OSD is at 192, it

means the panel is at its Full Dynamic Range. In order to

prevent saturation of Full Dynamic range and data, one of

R/G/B is fixed at 192, and the other two is lowered to find

the desired value.

(4) Adj. condition : normal temperature

1) Surrounding Temperature : 25 ºC ± 5 ºC

2) Warm-up time: About 5 Min

3) Surrounding Humidity : 20 % ~ 80 %

4.3.2 Equipment

1) Color Analyzer: CA-210 (LED Module : CH 14)

2) Adj. Computer(During auto adj., RS-232C protocol is

needed)

3) Adjust Remocon

4) Video Signal Generator MSPG-925F 720p/216-Gray

4) Video Signal Generator MSPG-925F 720p/216-Gray

(Model:217, Pattern:78)

-> Only when internal pattern is not available

A

Color Analyzer Matrix should be calibrated using CS-1000

4.3.3. Equipment connection MAP

D-sub to D-sub

DVI-D to HDMI or HDMI to HDMI

For HDMI EDID

For Analog EDID

Co lo r An alyzer

Co m p ut er

Pat t ern Gen erat o r

RS -232C

RS -232C

RS -232C

Probe

Signal Source

* If TV internal pattern is used, not needed

- 11 -

4.3.4. Adj. Command (Protocol)

<Command Format>

- LEN: Number of Data Byte to be sent

- CMD: Command

- VAL: FOS Data value

- CS: Checksum of sent data

- A: Acknowledge

Ex) [Send: JA_00_DD] / [Ack: A_00_okDDX]

- CMD: Command

- VAL: FOS Data value

- CS: Checksum of sent data

- A: Acknowledge

Ex) [Send: JA_00_DD] / [Ack: A_00_okDDX]

A

RS-232C Command used during auto-adj.

Ex) wb 00 00 -> Begin white balance auto-adj.

wb 00 10 -> Gain adj.

ja 00 ff -> Adj. data

jb 00 c0

...

...

wb 00 1f -> Gain adj. completed

ja 00 ff -> Adj. data

jb 00 c0

...

...

wb 00 1f -> Gain adj. completed

*(wb 00 20(start), wb 00 2f(end)) -> Off-set adj.

wb 00 ff -> End white balance auto-adj.

A

Adj. Map

4.3.5. Adj. method

(1) Auto adj. method

1) Set TV in adj. mode using POWER ON key.

2) Zero calibrate probe then place it on the center of the

2) Zero calibrate probe then place it on the center of the

Display.

3) Connect Cable (RS-232C)

4) Select mode in adj. Program and begin adjustment.

5) When adj. is complete (OK Sing), check adj. status pre

4) Select mode in adj. Program and begin adjustment.

5) When adj. is complete (OK Sing), check adj. status pre

mode. (Warm, Medium, Cool)

6) Remove probe and RS-232C cable to complete adj.

A

W/B Adj. must begin as start command “wb 00 00” , and

finish as end command “wb 00 ff”, and Adj. offset if need.

finish as end command “wb 00 ff”, and Adj. offset if need.

(2) Manual adj. method

1) Set TV in Adj. mode using POWER ON

2) Zero Calibrate the probe of Color Analyzer, then place it

2) Zero Calibrate the probe of Color Analyzer, then place it

on the center of LCD module within 10cm of the surface.

3) Press ADJ key -> EZ adjust using adj. R/C -> 7. White-

Balance then press the cursor to the right (KEY

G

).

(When KEY(

G

) is pressed 216 Gray internal pattern will

be displayed)

4) One of R Gain / G Gain / B Gain should be fixed at 192,

and the rest will be lowered to meet the desired value.

5) Adj. is performed in COOL, MEDIUM, WARM 3 modes

of color temperature.

A

If internal pattern is not available, use RF input. In EZ

Adj. menu 7.White Balance, you can select one of 2

Test-pattern: ON, OFF. Default is inner(ON). By

selecting OFF, you can adjust using RF signal in 216

Gray pattern.

Adj. menu 7.White Balance, you can select one of 2

Test-pattern: ON, OFF. Default is inner(ON). By

selecting OFF, you can adjust using RF signal in 216

Gray pattern.

A

Adj. condition and cautionary items

1) Lighting condition in surrounding area

Surrounding lighting should be lower 10 lux. Try to

isolate adj. area into dark surrounding.

isolate adj. area into dark surrounding.

2) Probe location

: Color Analyzer (CA-210) probe should be within 10

cm and perpendicular of the module surface (80° ~

100°)

cm and perpendicular of the module surface (80° ~

100°)

3) Aging time

- After Aging Start, Keep the Power ON status during

5 Minutes.

- In case of LCD, Back-light on should be checked

using no signal or Full-white pattern.

LEN

CMD

VAL

CS

RS-232C COMMAND

Explanation

[CMD

ID

DATA]

wb

00

00

Begin White Balance adj.

wb

00

10

Gain adj.(internal white pattern)

wb

00

1f

Gain adj. completed

wb

00

20

Offset adj.(internal white pattern)

wb

00

2f

Offset adj. completed

wb

00

ff

ITEM

Command

Data Range

Default

(lower case ASCII)

(Hex.)

(Decimal)

Cmd 1

Cmd 2

Min

Max

Cool

R-Gain

j

g

00

C0

G-Gain

j

h

00

C0

B-Gain

j

i

00

C0

R-Cut

G-Cut

B-Cut

Medium

R-Gain

j

a

00

C0

G-Gain

j

b

00

C0

B-Gain

j

c

00

C0

R-Cut

G-Cut

B-Cut

Warm

R-Gain

j

d

00

C0

G-Gain

j

e

00

C0

B-Gain

j

f

00

C0

R-Cut

G-Cut

- 12 -

4.3.6. Reference (White Balance Adj. coordinate

and temperature)

A

Luminance : 216 Gray

A

Standard color coordinate and temperature using CS-1000

(over 66cm(26 inch))

(over 66cm(26 inch))

A

Standard color coordinate and temperature using CA-210

(CH 14)

(CH 14)

4.4. EYE-Q function check

Step 1) Turn on TV

Step 2) Press EYE key of Adj. R/C

Step 3) Cover the Eye Q II sensor on the front of the using

your hand and wait for 6 seconds

Step 4) Confirm that R/G/B value is lower than 10 of the “Raw

Data (Sensor data, Back light)”. If after 6 seconds,

R/G/B value is not lower than 10, replace Eye Q II

sensor.

GP2

Aging time

(Min)

Cool

Medium

Warm

x

y

x

y

x

y

269

273

285

293

313

329

1

0-2

280

291

296

311

319

340

2

3-5

278

288

294

308

317

338

3

6-9

276

285

292

305

315

335

4

10-19

274

282

290

302

313

332

5

20-35

273

279

289

299

312

329

6

36-49

270

276

287

296

310

326

7

50-79

269

273

286

293

308

323

8

Over 80

269

273

285

293

308

323

1) Edge / IOP LED Models

4.3.7 Local Dimming Inspection

4.3.8 IOP LED models with local dimming

Press ‘TILT” key of the Adj. R/C and check moving patterns.

The black cross-bar patterns moves from top-left to Bottom-right.

If local dimming function does not work, a whole screen shows full white.

Edge LED models with local dimming

1) Press ‘TILT” key of the Adj. R/C and check moving patterns.

The black bar patterns moves from left to right.If local dimming function

does not work, a whole screen shows full white.

Step 5) Remove your hand from the Eye Q II sensor and wait

for 6 seconds.

Step 6) Confirm that “ok” pop up. If change is not seen,

replace Eye Q II sensor.

4.5. Option selection per country

(1) Overview

- Option selection is only done for models in Non-USA

- Applied model: LC03E Chassis applied None USA model

(CHINA, HONGKONG)

(2) Method

1) Press ADJ key on the Adj. R/C, then select Country

Group Menu

2) Depending on destination, select KR or US, then on the

lower Country option, select US, CA, MX. Selection is

done using +, - KEY.

done using +, - KEY.

4.8. Tool Option selection

- Method : Press Adj. key on the Adj. R/C, then select Tool

option.

4.9. Ship-out mode check(In-stop)

After final inspection, press IN-STOP key of the Adj. R/C and

check that the unit goes to Stand-by mode.

After final inspection, Always turn on the Mechanical S/W.

check that the unit goes to Stand-by mode.

After final inspection, Always turn on the Mechanical S/W.

5.1. Method

- Check that Power Cord is fully inserted to the SET.

(If loose, re-insert)

- Unit fully inserted Power cord, Antenna cable and A/V

arrive to the auto-check process.

- Connect D-terminal to AV JACK TESTER

- Auto CONTROLLER(GWS103-4) ON

- Perform GND TEST

- If NG, Buzzer will sound to inform the operator.

- If OK, changeover to I/P check automatically.

- Auto CONTROLLER(GWS103-4) ON

- Perform GND TEST

- If NG, Buzzer will sound to inform the operator.

- If OK, changeover to I/P check automatically.

(Remove CORD, A/V form AV JACK BOX)

- Perform I/P test

- If NG, Buzzer will sound to inform the operator.

- If OK, Good lamp will lit up and the stopper will allow the

- If NG, Buzzer will sound to inform the operator.

- If OK, Good lamp will lit up and the stopper will allow the

pallet to move on to next process.

5.2. Checkpoint

• TEST voltage

- GND: 1.5 KV / min at 100 mA

- SIGNAL: 3 KV / min at 100 mA

- SIGNAL: 3 KV / min at 100 mA

• TEST time: 1 second

• TEST POINT

• TEST POINT

- GND TEST = POWER CORD GND & SIGNAL CABLE

METAL GND

NEUTRAL

• LEAKAGE CURRENT: At 0.5 mArms

Mode

Color Coordination

Temp

∆UV

x

y

COOL

0.269

0.273

13000 K

0.0000

MEDIUM

0.285

0.293

9300 K

0.0000

WARM

0.313

0.329

6500 K

0.0000

Mode

Color Coordination

Temp

∆UV

x

y

COOL

0.269 ± 0.002 0.273 ± 0.002 13000 K 0.0000

MEDIUM 0.285 ± 0.002 0.293 ± 0.002 9300 K

0.0000

WARM

0.313 ± 0.002 0.329 ± 0.002 6500 K

0.0000

▪ Standard color coordinate and temperature using

CA-210(CH-14) – by aging time

MODEL

Tool 1

Tool 2

Tool 3

Tool 4

Tool 5

42LE85**

24896

32023

64572

14764

2995

Click on the first or last page to see other 47LX9550-CA (CHASSIS:LC03M) service manuals if exist.