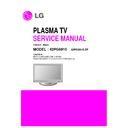

LG 42PG6910-ZF (CHASSIS:PD84A) Service Manual ▷ View online

2) 50” Module

- 5 -

Display Screen Device

Aspect Ratio

PDP Module

Operating Environment

Storage Environment

Input Voltage

1

2

3

4

5

6

No

Item

Specification

Remark

50 inch Wide Color Display Module

16:9

PDP50G1####,

RGB Closed Type Glass Filter

1)Temp.

: 0 ~ 40deg

2)Humidity : 20 ~ 80%

3)Temp.

: -20 ~ 60deg

4)Humidity : 10 ~ 90%

100-240V~, 50/60Hz

PDP

LGE SPEC.

Maker : LG

Market

Broadcasting system

Receiving system

Scart Jack (2EA)

Video Input (2EA)

S-Video Input (1EA)

Component Input (1EA)

RGB Input

HDMI Input(3EA)

Audio Input (4EA)

1

2

3

4

5

6

7

8

9

10

No

Item

Specification

Remark

UK, France, Germany, Spain, Sweden,

Finland, Italy

1) PAL-BG

2) PAL-DK

3) PAL-I, I’

4) DVB-T(ID TV)

5) SECAM-L/L’

Analog: Upper Heterodyne

Digital: COFDM

PAL, SECAM

PAL, SECAM, NTSC

PAL, SECAM, NTSC

Y/Cb/Cr, Y/Pb/Pr

RGB-PC

HDMI-PC(HDMI 1 only)

HDMI-DTV & SOUND

PC Audio, Component, AV

Scart1 is Full scart and support RF-

OUT(Analog).

Scart2 is Half scart and support DTV/MNT-

OUT.

4 System: PAL, SECAM, NTSC, PAL60

4 System: PAL, SECAM, NTSC, PAL60

Rear 2EA

Side 1EA

L/R Input

V

Model General Specification

- 6 -

1. Application Range

This spec sheet is applied all of the PD84A chassis by

manufacturing LG TV Plant or sort plants.

manufacturing LG TV Plant or sort plants.

2. Specification

Caution: The module keeping condition

O

The module keeping condition: The normal temperature

condition(more than 15°C)

--> Immediately the line supply.

--> Immediately the line supply.

O

The module keeping condition: 0°C

--> The module must be kept for more than 2 hours at the

normal temperature.

O

The module keeping condition: -20°C

--> The module must be kept for more than 3 hours at the

normal temperature.

O

The case of Gu-mi factory at the winter season.

--> The module must be kept for more than 5 minutes at

the heating zone(40°C~45°C).

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer.

However, the use of isolation transformer will help protect

test instrument.

However, the use of isolation transformer will help protect

test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

there is no specific designation.

(4) The input voltage of the receiver must keep 100~240V,

50/60Hz.

(5) The receiver must be operated for about 5 minutes prior to

the adjustment.

O

After RGB Full White in HEAT-RUN Mode, the receiver

must be operated prior to the adjustment.

O

Enter into HEAT-RUN MODE

1) Press the POWER ON KEY on R/C for adjustment.

2) OSD display and screen display PATTERN MODE.

2) OSD display and screen display PATTERN MODE.

- Set is activated HEAT run without signal generator in this

mode.

- Caution: If you turn on a still screen more than 20 minutes

(Especially digital pattern, cross hatch pattern), an after

image may be occur in the black level part of the

screen.

image may be occur in the black level part of the

screen.

PCB assembly Adjustment Method

Caution: Using ‘power on’ button of the control R/C, power on

TV.

TV.

[

ADC Calibration Protocol (RS232)

- Baud rate : 115200 bps

- RS232 Host : PC

- echo : none

- RS232 Host : PC

- echo : none

3. ADC Adjustment

3-1. Adjustment of AV(CVBS)

O

Standard equipment : 802F Pattern Generator. Master

Pattern Generator(MSPG-925, etc) or same product

O

Required Equipment

1) Remote controller for adjustment

2) MSPG-925FS Pattern Generator (Which has Video

2) MSPG-925FS Pattern Generator (Which has Video

Signal: 7 Color Bar Pattern shown in Fig. 1).

- Model: 202 / Pattern: 65 EC and FC model use PAL-

- Model: 202 / Pattern: 65 EC and FC model use PAL-

BGDHI (composite signal)

(1) Input the Video signal: 7 color Bar signal into AV3.

(2) Set the PSM to Vivid mode in the Picture menu

(2) Set the PSM to Vivid mode in the Picture menu

(3) Press INSTART key on R/C for adjustment.

(4) Press the

(4) Press the

G

(Vol. +) key operate to set, then it becomes

automatically.

Auto-RGB OK means completed adjustment

Auto-RGB OK means completed adjustment

ADJUSTMENT INSTRUCTION

<Fig. 1> Color Bar Signal

- 7 -

3-2. Adjustment of Component

O

Standard equipment : 802F Pattern Generator. Master

Pattern Generator(MSPG-925, etc) or same product

O

Required Equipments

1) Remote controller for adjustment

2) MSPG-925FS Pattern Generator (Which has Video

2) MSPG-925FS Pattern Generator (Which has Video

Signal: 7 Color Bar Pattern shown in Fig. 1).

==> Model: 215 / Pattern: 65

==> Model: 215 / Pattern: 65

(1) Input the Component 720p/50Hz 7 Color Bar(MSPG-

925FS model: 215, pattern: 65) signal into Component.

(2) Set the PSM to Vivid mode in the Picture menu.

(3) Press IN-START key on R/C for adjustment

(4) Press the

(4) Press the

G

(Vol. +) key to operate the set, then it

becomes automatically

(5) Auto-RGB OK means the adjustment is completed

3-3. Adjustment of RGB

O

Standard equipment: PC Pattern Generator(VG828,

VG854, 801GF, MSP3240A) or same product

O

Required Equipments

1) Remote controller for adjustment

2) MSPG-925FS Pattern Generator

2) MSPG-925FS Pattern Generator

(Which has Video Signal: 7 Color Bar Pattern shown in

Fig. 1).

Fig. 1).

(1) Input the PC 1024x768 @ 60Hz 7 color bar (MSPG-

925FS, Model: 3, Pattern: 65) into RGB. (using D-sub to D-

sub cable)

sub cable)

(2) Set the PSM to Vivid mode in Picture menu.

(3) Press the IN-START key on R/C for adjustment.

(4) Press the

(4) Press the

G

(Vol. +) key operate To set , then it becomes

automatically.

(5) Auto-RGB OK means adjustment is completed.

(6) Press the

(6) Press the

G

(Vol. +) key to operate the set, then it

becomes automatically

(7) Auto-RGB OK means the adjustment is completed

3-4. Adjustment of SCART-RGB

O

Standard equipment : Master Pattern Generator(MSPG-

925, etc) or same product

O

Required Equipments

1) Remote controller for adjustment

2) MSPG-925FS Pattern Generator (Which has Video

2) MSPG-925FS Pattern Generator (Which has Video

Signal: 8 Color Bar Pattern shown in Fig. 2).

==> Model: 232/ Pattern: 8

==> Model: 232/ Pattern: 8

(1) Input the SCART-RGB 8 Color Bar(MSPG-925FS model:

232, pattern: 8) signal into AV1. (using Full Scart Cable)

(2) Set the PSM to Vivid mode in the Picture menu.

(3) Press IN-START key on R/C for adjustment

(4) Press the

(4) Press the

G

(Vol. +) key to operate the set, then it

becomes automatically

(5) Auto-RGB OK means the adjustment is completed

4. Channel Memory Setting Method

Recovery the channel memory by adjust R/C.

You can set channel memory by R/C for adjustment

(1) Press ADJ key on R/C for adjustment.

(2) Press VOL + key on “Channel Recover”

(1) Press ADJ key on R/C for adjustment.

(2) Press VOL + key on “Channel Recover”

5. PCMCIA CARD Checking Method

You must adjust DTV ## Channel and insert PCMCIA

CARD to socket.

CARD to socket.

(1) If PCMCIA CARD works normally, normal signals display

on screen.

But it works abnormally, “No CA module” words display on

screen.

But it works abnormally, “No CA module” words display on

screen.

[

Caution : Before power off, input mode must be changed

RF mode.

<Fig. 1> Color Bar Signal

<Fig. 2> 8 Color 16 Step Gray Signal

<Fig. 1> Color Bar Signal

SET Assembly Adjustment Method

Caution: Each PCB assembly must be checked by check JIG set.

(Because power PCB Assembly damages to PDP

Module, especially be careful)

Module, especially be careful)

6. 50” POWER PCB Ass’y Voltage

Adjustment

(Va, Vs Voltage Adjustment)

6-1. Model Name :

50PG6900,50PG6910

6-2. Adjustment Method

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D. M..M. to Va pin of P811, connect -

2) Connect + terminal of D. M..M. to Va pin of P811, connect -

terminal to GND pin of P811.

3) After turning VR901,voltage of D.M.M adjustment as same

as Va voltage which on label of panel right/top (deviation;

±0.5V)

±0.5V)

(2) Vs Adjustment

1) Input signal : RF noise signal

2) Connect + terminal of D. M..M. to Vs pin of P811, connect -

2) Connect + terminal of D. M..M. to Vs pin of P811, connect -

terminal to GND pin of P811.

3) After turning VR 951, voltage of D.M.M adjustment as same

as Vs voltage which on label of panel right/top (deviation ;

±0.5V)

±0.5V)

7. 42” POWER PCB Ass’y Voltage

Adjustment

(Va, Vs Voltage Adjustment)

7-1. Model Name:

42PG6900,42PG6910

7-2. Adjustment Method

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D. M..M. to Va pin of P811, connect -

2) Connect + terminal of D. M..M. to Va pin of P811, connect -

terminal to GND pin of P811.

3) After turning VR901,voltage of D.M.M adjustment as same

as Va voltage which on label of panel right/top (deviation;

±0.5V)

±0.5V)

(2) Vs Adjustment

1) Input signal : RF noise signal

2) Connect + terminal of D. M..M. to Vs pin of P811, connect -

2) Connect + terminal of D. M..M. to Vs pin of P811, connect -

terminal to GND pin of P811.

3) After turning VR 951, voltage of D.M.M adjustment as same

as Vs voltage which on label of panel right/top (deviation ;

±0.5V)

±0.5V)

8. EDID(The Extended Display

Identification Data) / DDC

(Display Data Channel) Download

(Display Data Channel) Download

8-1. Required Test Equipment

(1) Adjusting PC with S/W for writing EDID Data.(S/W: EDID

TESTER Ver.2.5)

(2) A Jig for EDID Download

(3) Cable : Serial(9Pin or USB) to D-sub 15Pin cable, D-sub

(3) Cable : Serial(9Pin or USB) to D-sub 15Pin cable, D-sub

15Pin cable, DVI to HDMI cable.

8-2. Setting of Device

- 8 -

<Fig. 3> 50inch Power PCB Assy Voltage adjustment

<Fig. 4> 42inch Power PCB Assy Voltage adjustment

<Fig. 5> Connection Diagram of DDC download

Click on the first or last page to see other 42PG6910-ZF (CHASSIS:PD84A) service manuals if exist.