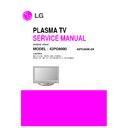

LG 42PG6000-ZA (CHASSIS:PD81A) Service Manual ▷ View online

- 6 -

ADJUSTMENT INSTRUCTION

1. Application Object

These instructions are applied all of the 42” PLASMA TV,

PD81A

PD81A

Chassis.

2. Note

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

there is no specific designation.

(4) The input voltage of the receiver must keep 100-240V~,

50/60Hz.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

O

After RGB Full white HEAT-RUN Mode, the receiver must

be operated prior to adjustment.

O

Enter into HEAT-RUN MODE

1) Press the POWER ON KEY on R/C for adjustment.

2) OSD display and screen display PATTERN MODE.

2) OSD display and screen display PATTERN MODE.

- Select “3. Test Pattern” by using

D

/

E

(CH+/-) and

press ENTER(

V

)

- Select “White” by using (

F

/

G

VOL+/-) and press

ENTER(

V

)

* Set is activated HEAT-RUN without signal generator in

this mode.

* Single color pattern(RED/BLUE/GREEN) of HEAT-RUN

mode uses to check PANEL.

3. S/W auto download using the USB

Memory stick

(1) Insert the USB memory sick the PCB ASSEMBLY.

(2) Using ‘power on’ button of the control R/C, power on TV.

(3) S/W download process is executed automatically.

(2) Using ‘power on’ button of the control R/C, power on TV.

(3) S/W download process is executed automatically.

4. Auto-control adjustment process

V

All adjustment process is executed one time through RS-232C.

V

Command send -> ADC Calibration -> Model name

download -> EDID download.

V

Adjsutment process protocol(RS-232C)

5. Manual model name download

(1) Press ADJ KEY on R/C for model name D/L.

(2) Select “0.Model Option” and press ENTER(

(2) Select “0.Model Option” and press ENTER(

V

).

(3) Select model name by using

D

/

E

(CH+/-)and press

ENTER(

V

).

* Using ‘power on’ button off the control R/C, power on TV.

All adjustment process is executed one time through RS-232C.

Do not connect extrenal input calbe.

All adjustment process is executed one time through RS-232C.

Do not connect extrenal input calbe.

* Using ‘power on’ button of the control R/C, power on TV.

USB file(EPK) version must be bigger than downloaded

version of main B/D.

USB file(EPK) version must be bigger than downloaded

version of main B/D.

* Using ‘power on’ button off the control R/C, power on TV.

1

2

3

4

5

6

7

8

9

10

Ready

ADC

ADC

Confirmation

ADC

Mode Out

Download

Mode In

EDID

Download

Check EDID

Status

Define model

name

Adjustment

Confirmation

Download

Mode Out

NO

Item

Remark

CMD1 CMD2

Data 0

a

a

a

a

a

a

a

a

a

a

d

d

d

d

e

e

e

e

e

e

0

0

9

0

0

0~4,9

0~4,9

1~7

9

0

0

1

9

9

0

1

2

5

9

9

Ready

ADC start

Transmitting adjustment mode In

instruction, operate adjustment command.

All=0 ; HDMI1,2,3,4=1,2,3,4 ; RGB=9

All=0 ; HDMI1,2,3,4=1,2,3,4 ; RGB=9

Model define index(Data0) are listed at

next table.

EDID data existence check in SET

assembly

a

e

5

3

42PG6000-ZA

CMD1

CMD2

Data 0

Remark

42PG6000-ZA

56000000

Model Name

Model Option Value

- 7 -

6. Manual ADC Adjustment

V

Adjustment is done using internal ADC, so input signal is

not necessary.

V

Do not connect external input cable.

6-1. Required Equipment

(1) Press ADJ KEY on R/C and enter EZ ADJUST.

(2) Select “1.EDID D/L” by using

(2) Select “1.EDID D/L” by using

D

/

E

(CH+/-) and press

ENTER(

V

).

(3) Select “Start” by using

F

/

G

(VOL+/-) and press ENTER(

V

).

(4) ADC Adjustment is executed automatically.

7. EDID Download

7-1. Required Equipment

(1) Press ADJ KEY on R/C and enter EZ ADJUST.

(2) Select “5.EDID D/L” by using

(2) Select “5.EDID D/L” by using

D

/

E

(CH+/-) and press

ENTER(

V

).

(3) Select “Start” and press ENTER(

V

).

(4) EDID download is executed automatically.

(5) Press EXIT key on R/C.

(5) Press EXIT key on R/C.

7-2. EDID DATA

(1) HDMI1(256bytes)

(2) RGB(128bytes)

-> Detail EDID Options are below (

ⓐ

,

ⓑ

,

ⓒ

,

ⓓ

,

ⓔ

)

ⓐ

Product ID

ⓑ

Serial No

=> Controlled on production line

ⓒ

Month, Year

=> Controlled on production line:

ex) Monthly: ‘11’ -> ‘0B’

Year: ‘2007’ -> ‘11’

ⓓ

Model Name(Hex)

ⓔ

Checksum

=> Changeable by total EDID data.

8. PCMCIA CARD Checking Method

: You must adjust DTV29 Channel and insert PCMCIA CARD

to socket.

1) If PCMCIA CARD works normally, normal signals display

on screen. But it works abnormally, “No CA module” words

display on screen.

display on screen.

*Do not connect HDMI and RGB cable.

NO SIGNAL or White noise

NO SIGNAL

RF Input

AV / Component / RGB input

42PG6000-ZA

EDID MODEL

Product ID

FUCTION

Model Name

Analog

Digital

40239(9D2F)

40240(9D30)

42PG6000-ZA

42PG6000

00 00 00 FC 00 34 32 50 47 36 30 30 30 0A 20 20 20 20

Model Name

Model Name(Hex)

* Set up “RF mode” before launching products.

- 8 -

9. POWER PCB Assy Voltage

Adjustments

(Va, Vs Voltage adjustments)

9-1. Test Equipment :

D.M.M. 1EA

9-2.Connection Diagram for Measuring

: refer to Fig.1

9-3. Adjustment Method

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M to Va pin of P811, connect

2) Connect + terminal of D.M.M to Va pin of P811, connect

- terminal to GND pin of P811.

3) After turning VR901, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

(Deviation; ±0.5V)

(2) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P811, connect

– terminal to GND pin of P811.

2) After turning VR951, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

(Deviation; ±0.5V)

10. Adjustment of White Balance

10-1. Required Equipment

(1) Color Analyzer : CS-100, CA-100+(CH.10), CA-

210(CH.10))

* Please adjust CA-100+/CA-210 by CS-1000 before

* Please adjust CA-100+/CA-210 by CS-1000 before

measuring.

-> You should use Channel 10 which is Matrix

compensated.

N

Color temperature standards according to CSM and Module.

N

Change target luminance and range of the Auto adjustment

W/B equipment.

N

White balance adjustment coordinate and color temperature.

Each PCB assembly must be checked by check JIG set.

(Because power PCB Assembly damages to PDP Module,

especially be careful)

(Because power PCB Assembly damages to PDP Module,

especially be careful)

(Fig.1) Connection diagram of power adjustment for measuring

* Before adjusting White-balance, the AV ADC should be done.

If ADC status were “NG”, Need to ADC adjustment.

PLASMA

Remark

11000K

9300K

6500K

Cool

Normal

Warm

CSM

65

20

Range

Target luminance

0.276

0.283

0.000

0.276±0.002

0.283±0.002

0.000

0.276±0.002

0.283±0.002

0.000

X

y

uv

Cool

CS-1000

CA-100+(CH.10) CA-210(CH.10)

0.285

0.293

0.000

0.285±0.002

0.293±0.002

0.000

0.285±0.002

0.293±0.002

0.000

X

y

uv

Medium

CS-1000

CA-100+(CH.10) CA-210(CH.10)

0.313

0.329

0.003

0.313±0.002

0.329±0.002

0.003

0.313±0.002

0.329±0.002

0.003

X

y

uv

Warm

CS-1000

CA-100+(CH.10) CA-210(CH.10)

- 9 -

10-2. Connection Picture of the Measuring

Instrument(On Automatic control)

(1) Inside PATTERN is used when W/B is controlled. Connect

to auto controller or push control R/C IN-START -> Enter

the mode of White-Balance, the pattern will come out.

the mode of White-Balance, the pattern will come out.

10-3. Auto-control interface and directions

(1) Adjust in the place where the influx of light like floodlight

around is blocked.(illumination is less than 10ux)

(2) Measure and adjust after sticking the Color Analyzer(CA-

100+, CA210) to the side of the module.

(3) Aging time

- After aging start, keep the power on(no suspension of

power supply) and heat-run over 15 minutes.

- keep white pattern using inside pattern.

A

Auto adjustment Map(RS-232C)

11. Adjustment of White Balance

(1) Press ADJ KEY on R/C and enter EZ ADJUST.

Select “3. Test Pattern” by using

D

/

E

(CH+/-) and press

ENTER(

V

)

Select “White” by using

F

/

G

(VOL+/-) and press ENTER(

V

)

and heat run over 15minutes.

(2) Zero Calibrate CA-100+/CA-210, and when controlling,

stick the sensor to the center of PDP module.

(3) Press ADJ KEY on R/C and enter EZ ADJUST.

Select “2. White Balance” and press

G

(VOL +).

Set test-pattern on and display inside pattern.

(5) Control is carried out on three color temperatures, COOL,

MEDIUM,WARM.

(Control is carried out thress times)

(Control is carried out thress times)

<Temperature : COOL>

- R-Cut / G-Cut / B-Cut is set to 64/

- Control R-Gain and G-Gain.

- Each Gain is limited to 192.

- Control R-Gain and G-Gain.

- Each Gain is limited to 192.

<Temperature : MEDIUM>

- R-Cut / G-Cut / B-Cut is set to 64/

- Control R-Gain and G-Gain.

- Each Gain is limited to 192.

- Control R-Gain and G-Gain.

- Each Gain is limited to 192.

<Temperature : WARM>

- R-Cut / G-Cut / B-Cut is set to 64/

- Control G-Gain and B-Gain.

- Each Gain is limited to 192.

- Control G-Gain and B-Gain.

- Each Gain is limited to 192.

12. Input the Shipping Option Data

1) Push the IN-START key in a Adjust Remocon.

2) Input the Option Number that was specified in the BOM, into

2) Input the Option Number that was specified in the BOM, into

the Shipping area.

3) The work is finished, Push

V

Key.

13. Set Information

(Serial No& Model name)

13-1. Check the serial number & Model Name

(1) Push the menu button in DTV mode.

(2) Select the SETUP -> Diagnostics -> To set.

(3) Check the Serial Number.

(2) Select the SETUP -> Diagnostics -> To set.

(3) Check the Serial Number.

(Fig.6) Auto AV(CVBS) Color Balance Test Pattern

Full White Pattern

RS-232C Communication

CA-210

Color

ANALYZER

TYPE : CA-210

R Gain

G Gain

B Gain

R Offset

G Offset

B Offset

Cool

Med

Warm

Cool

Med

Warm

jg

Ja

js

00

192

192

192

255

jh

Jb

je

00

192

192

192

255

ji

Jc

jf

00

192

192

192

255

65

65

62

128

56

56

53

128

71

70

76

128

RS-232C COMMAND

[CMD ID DATA]

Min

CENTER

(DEFAULT)

MAX

42PG1

Click on the first or last page to see other 42PG6000-ZA (CHASSIS:PD81A) service manuals if exist.