LG 42LN5200 (CHASSIS:LT36M) Service Manual ▷ View online

- 11 -

4. Total Assembly line process

4.1. Adjustment Preparation

■ W/B Equipment condition

CA210 : CH14, Test signal : Inner pattern (80IRE) – in case of

LED back light

■ Above 5 minutes H/run in the inner pattern. (“power on” key of

adjust remote control)

► The spec of color temperature and coordinate

Model

Mode

Color Temp

Color coordinate

Remark

All

Cool (C50)

13,000k

x = 0.271 (±0.002)

y = 0.270 (±0.002)

※

Test signal

- Inner pattern for W/B adjust

- External white pattern

(80IRE, 204gray)

Medium (0)

9,300k

x = 0.286 (±0.002)

y = 0.289 (±0.002)

Warm (W50)

6,500k

x = 0.313 (±0.002)

y = 0.329 (±0.002)

► CA210 : CH 14, Test signal : Inner pattern (80IRE)

- Standard color coordinate and temperature using CA-1000 (by

H/R time)

▪ Normal line

model: (normal line)LN5xxx, LA6xxx, LA7xxx, LA8xxx

H/R Time(Min)

Cool

Medium

Warm

x

y

x

x

y

x

271

270

286

289

313

329

1

0-2

283

287

298

306

322

342

2

3-5

282

285

297

304

321

340

3

6-9

281

284

296

303

320

339

4

10-19

279

281

294

300

318

336

5

20-35

277

277

292

296

316

332

6

36-49

275

274

290

293

314

329

7

50-79

273

272

288

291

312

327

8

80-119

272

271

287

290

311

326

9

Over 120

271

270

286

289

310

325

▪ Aging chamber line

model: (aging chamber)LN5xxx, LA6xxx, LA7xxx, LA8xxx

H/R Time(Min)

Cool

Medium

Warm

x

y

x

x

y

x

271

270

285

293

313

329

1

0-5

280

285

294

308

319

340

2

6-10

276

280

290

303

315

335

3

11-20

272

275

286

298

311

330

4

21-30

269

272

283

295

308

327

5

31-40

267

268

281

291

306

323

6

41-50

266

265

280

288

305

320

7

51-80

265

263

279

286

304

318

8

81-119

264

261

278

284

303

316

9

Over 120

264

260

278

283

303

315

※

Connecting picture of the measuring instrument

(On Automatic control)

Inside PATTERN is used when W/B is controlled. Connect to

auto controller or push Adjustment R/C POWER-ON -> Enter

the mode of White-Balance, the pattern will come out.

●

Auto-control interface and directions

(1) Adjust in the place where the influx of light like floodlight

around is blocked. (Illumination is less than 10ux).

(2) Adhere closely the Color Analyzer ( CA210 ) to the module

less than 10cm distance, keep it with the surface of the

Module and Color Analyzer’s Prove vertically.(80~100°).

(3) Aging time

- After aging start, keep the power on (no suspension of

power supply) and heat-run over 5 minutes.

- Using ‘no signal’ or ‘full white pattern’ or the others, check

the back light on.

● Auto adjustment Map(RS-232C)

RS-232C COMMAND

[ CMD ID DATA ]

Wb 00 00 White Balance Start

Wb 00 ff White Balance End

RS-232C COMMAND

[CMD ID DATA]

MIN

CENTER

(DEFAULT)

MAX

Cool

Mid

Warm

Cool

Mid

Warm

R Gain

jg

Ja

jd

00

172

192

192

192

G Gain

jh

Jb

je

00

172

192

192

192

B Gain

ji

Jc

jf

00

192

192

172

192

R Cut

64

64

64

128

G Cut

64

64

64

128

B Cut

64

64

64

128

- 12 -

*Manual W/B process using adjusts Remote control.(TBD)

■ Color analyzer(CA100+, CA210) should be used in the

calibrated ch by CS-1000

■ Operate the zero-calibration of the CA100+ or CA-210, then

stick sensor to the module when adjusting.

■ After enter Service Mode by pushing “ADJ” key,

■Enter White Balance by pushing “►” key at “8. White Balance”.

■ For manual adjustment, it is also possible by the following

sequence.

(1) Set TV in Adj. mode using POWER ON

(2) Zero Calibrate the probe of Color Analyzer, then place it on

the center of LCD module within 10cm of the surface

(3) Press ADJ key -> EZ adjust using adj. R/C -> 8. White-

Balance then press the cursor to the right (KEY►). When

KEY(►) is pressed 206 Gray internal pattern will be displayed.

(4) Adjust Cool modes

(i). Fix the one of R/G/B gain to 192 (default data) and decrease

the others

(If G gain is adjusted over 172 and R and B gain less than

192, increase G gain to 192 and increase R gain and B gain

same amount of increasing G gain.)

(ii). If G gain is less than 172,

Increase G gain by up to 172, and then increase R gain and

G gain same amount of increasing G gain.

(iii). If R gain or B gain is over 255,

Readjust G gain less than 172, Conform to R gain is 255 or B

gain is 255

(5) Adjust two modes (Medium / Warm) Fix the one of R/G/B gain

to 192 (default data) and decrease the others.

(6) Adj. is completed, Exit adjust mode using “EXIT” key on

Remote controller.

▪ If internal pattern is not available, use RF input. In EZ Adj. menu

8. White Balance, you can select one of 2 Test-pattern: ON,

OFF. Default is inner (ON). By selecting OFF, you can adjust

using RF signal in 206 Gray pattern.

※

CASE Cool

First adjust the coordinate far away from the target value(x, y).

(1) x, y > target

i) Decrease the R, G.

(2) x, y < target

i) First decrease the B gain,

ii) Decrease the one of the others.

(3) x > target , y< target

i) First decrease B, so make y a little more than the target.

ii) Adjust x value by decreasing the R

(4) x < target , y >target

i) First decrease B, so make x a little more than the target.

ii) Adjust x value by decreasing the G

How to adjust

(1) If G gain is adjusted over 172 and R gain and B gain less

than 192 , Adjust is O.K.

(2) If G gain is less than 172 , increase G gain by up to 172,

and then increase R gain and B gain same amount of

increasing G gain.

(3) If R gain or B gain is over 255 , Readjust G gain less than

172, Conform to R gain is 255 or B gain is 255

※

CASE Medium / Warm

First adjust the coordinate far away from the target value(x, y).

(1) x, y > target

i) Decrease the R, G.

(2) x, y < target

i) First decrease the B gain,

ii) Decrease the one of the others.

(3) x > target , y< target

i) First decrease B, so make y a little more than the target.

ii) Adjust x value by decreasing the R

(4) x < target , y >target

i) First decrease B, so make x a little more than the target.

ii) Adjust x value by decreasing the G

▪ After You finish all adjustments, Press “In-start” button and

compare Tool option and Area option value with its BOM, if it is

correctly same then unplug the AC cable. If it is not same, then

correct it same with BOM and unplug AC cable. For correct it to

the model’s module from factory JIG model.

▪ Push the “IN STOP KEY” after completing the function

inspection.

- 13 -

4.2. DPM operation confirmation

(Only Apply for MNT Model)

Check if Power LED Color and Power Consumption operate

as standard.

■ Set Input to RGB and connect D-sub cable to set

■ Measurement Condition: (100~240V@ 50/60Hz)

■ Confirm DPM operation at the state of screen without Signal

4.3. DDC EDID Write (HDMI 256Byte)

■ Connect HDMI Signal Cable to HDMI Jack.

■ Write EDID DATA to EEPROM(24C02) by using DDC2B

protocol.

■ Check whether written EDID data is correct or not.

* For SVC Ass’y, EDID have to be downloaded.

4.4. EDID DATA

1) All Data : HEXA Value

2) Changeable Data :

*: Serial No : Controlled / Data:01

**: Month : Controlled / Data:00

***:Year : Controlled

****:Check sum

- Auto Download

■ After enter Service Mode by pushing “ADJ” key,

■ Enter EDID D/L mode.

■ Enter “START” by pushing “OK” key.

※

Edid data and Model option download (RS232C)

NO

Item

CMD 1 CMD 2

Data 0

Enter

download

MODE

Download

‘Mode In’

A

A

0

0

When transfer

the ‘Mode In’,

Carry the com-

mand

Edid data

and Model

option

download

Download

A

E

00

10

Automatically

download

(The use of a

internal Data)

※

Caution

* Use the proper signal cable for EDID Download

- Analog EDID : Pin3 exists

- Digital EDID : Pin3 exists

=> Caution

- Never connect HDMI & D-sub Cable at the same time.

- Use the proper cables below for EDID Writing.

- Download HDMI1, HDMI2 separately because HDMI1 is

different from HDMI2.

For Analog EDID

For HDMI EDID

D-sub to D-sub

DVI-D to HDMI or HDMI to HDMI

No.

Item

Condition

Hex Data

1

Manufacturer ID

GSM

1E6D

2

Version

Digital : 1

01

3

Revision

Digital : 3

03

●

EDID DATA

(1) FHD 2D EDID Data

CheckSum

Physical Address (0x9E)

HDMI 1

42/25

10

HDMI 2

42/15

20

- 14 -

4.5. V-COM Adjust (Only CDMS Module)

■ Why need Vcom adjustment?

The Vcom (Common Voltage) is a Reference Voltage of

Liquid Crystal Driving.

→ Liquid Crystal need for Polarity Change with every frame.

- Adjust sequence

■ Press “P-only” key, enter to power only mode. And Press

“yellow” key to enter module inspection mode. After then,

Press “number 0” key, Flicker Pattern is displayed.

(Or After enter Service Mode by pushing “ADJ” key, then

Enter V-Com Adjust mode by pushing “►” key at “13.

V-Com”)

■ As pushing the right or the left button on the remote

controller, And find the V-COM value Which is no or

minimized the Flicker.

(If there is no flicker at default value, Press “P-only” key and

finish the VCOM adjustment.)

■ Push the OK key to store value. Then the message “Saving

OK” is pop.

■ Press the “P-only” key to finish VCOM adjustment.

4.6. Outgoing condition Configuration

■ When pressing IN-STOP key by SVC remocon, Red LED

are blinked alternatively. And then automatically turn off.

(Must not AC power OFF during blinking)

4.7. GND & Hi-pot test

4.7.1. GND & HI-POT auto-check preparation

(1) Check the POWER CABLE and SIGNAL CABE insertion

condition

4.7.2. GND & HI-POT auto-check

(1) Pallet moves in the station. (POWER CORD / AV CORD is

tightly inserted)

(2) Connect the AV JACK Tester.

(3) Controller (GWS103-4) on.

(4) GND Test (Auto)

- If Test is failed, Buzzer operates.

- If Test is passed, execute next process (Hi-pot test).

(Remove A/V CORD from A/V JACK BOX)

(5) HI-POT test (Auto)

- If Test is failed, Buzzer operates.

- If Test is passed, GOOD Lamp on and move to next

process automatically.

4.7.3. Checkpoint

(1) Test voltage

①

①

3 Poles

- GND: 1.5KV/min at 100mA

- SIGNAL: 3KV/min at 100mA

②

②

2 Poles

- SIGNAL: 3KV/min at 100mA

(2) TEST time: 1 second

(3) TEST POINT

①

①

3 Poles

- GND Test = POWER CORD GND and SIGNAL CABLE

GND.

- Hi-pot Test = POWER CORD GND and LIVE & NEUTRAL.

②

②

2 Poles

- Hi-pot Test = Accessible Metal and LIVE & NEUTRAL.

(4) LEAKAGE CURRENT: At 0.5mArms

5. Local Dimming Function Check

Step1) Turn on TV.

Step2) Press “P-only” key, enter to power only mode and

escape the “P-only” Mode by pressing “Exit” key

Step3) Press “Tilt” key, entrance to Local Dimming mode.

Step4) At the Local Dimming mode, module Edge Backlight

moving Top to bottom Back light of module moving

Step5) confirm the Local Dimming mode

Step6) Press “Exit” key

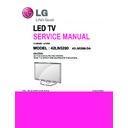

Row Line

Column Line

C

LC

C

ST

Panel

S

Y

S

T

E

Y

S

T

E

M

Gate Dri

ve

I

I

C

Source Drive IC

Circuit Block

Timing

Controller

Power

Block

V

COM

Gamma

Reference Voltage

Gamma Reference

Voltage

Data(R,G,B) & Control signal

Control signal

Data(R,G,B) &

Control signal

Interfac

e

TFT

Power Input

Power Input

Data Input

Data Input

V

COM

Liquid

Crystal

V

COM

Click on the first or last page to see other 42LN5200 (CHASSIS:LT36M) service manuals if exist.